PG96MSA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

28

A230219

A230220

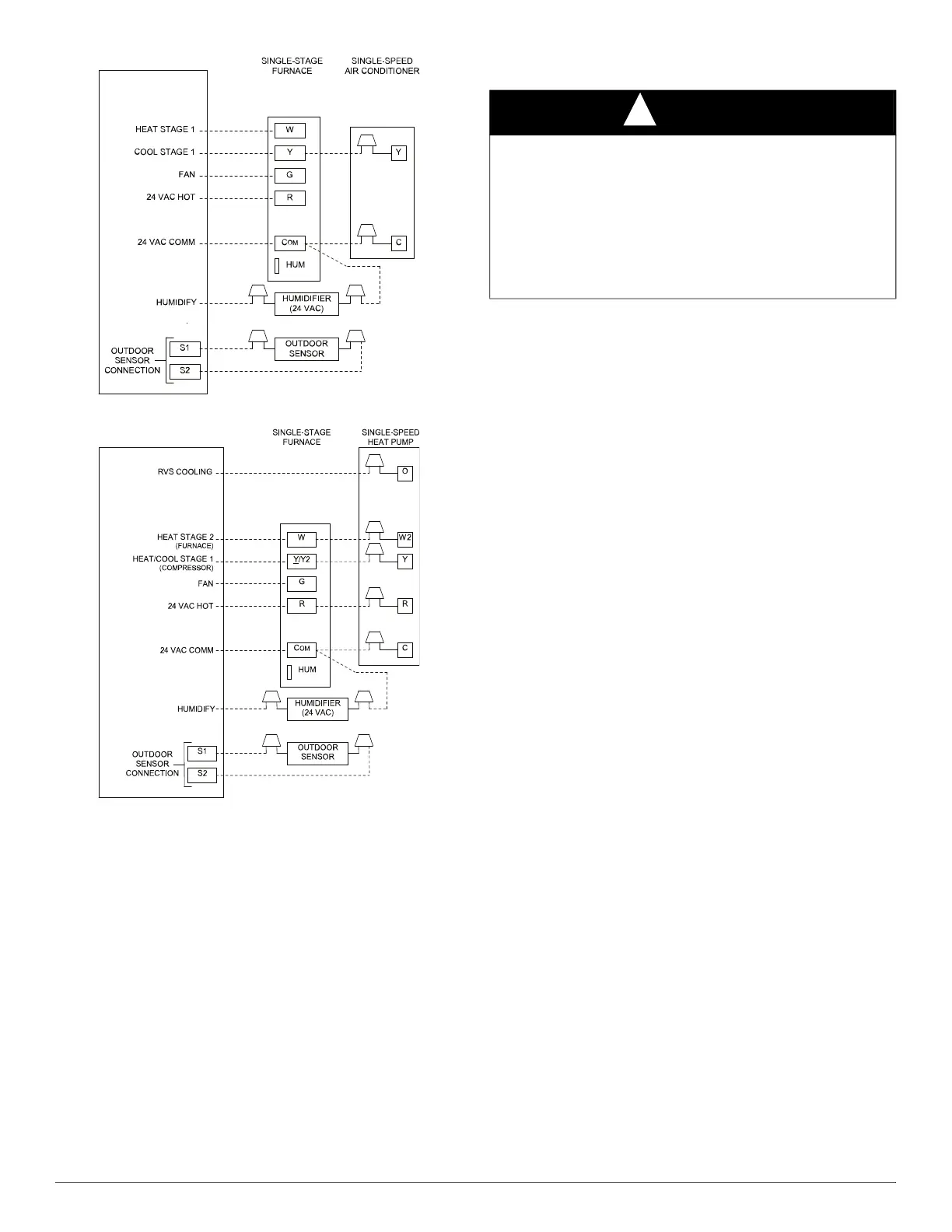

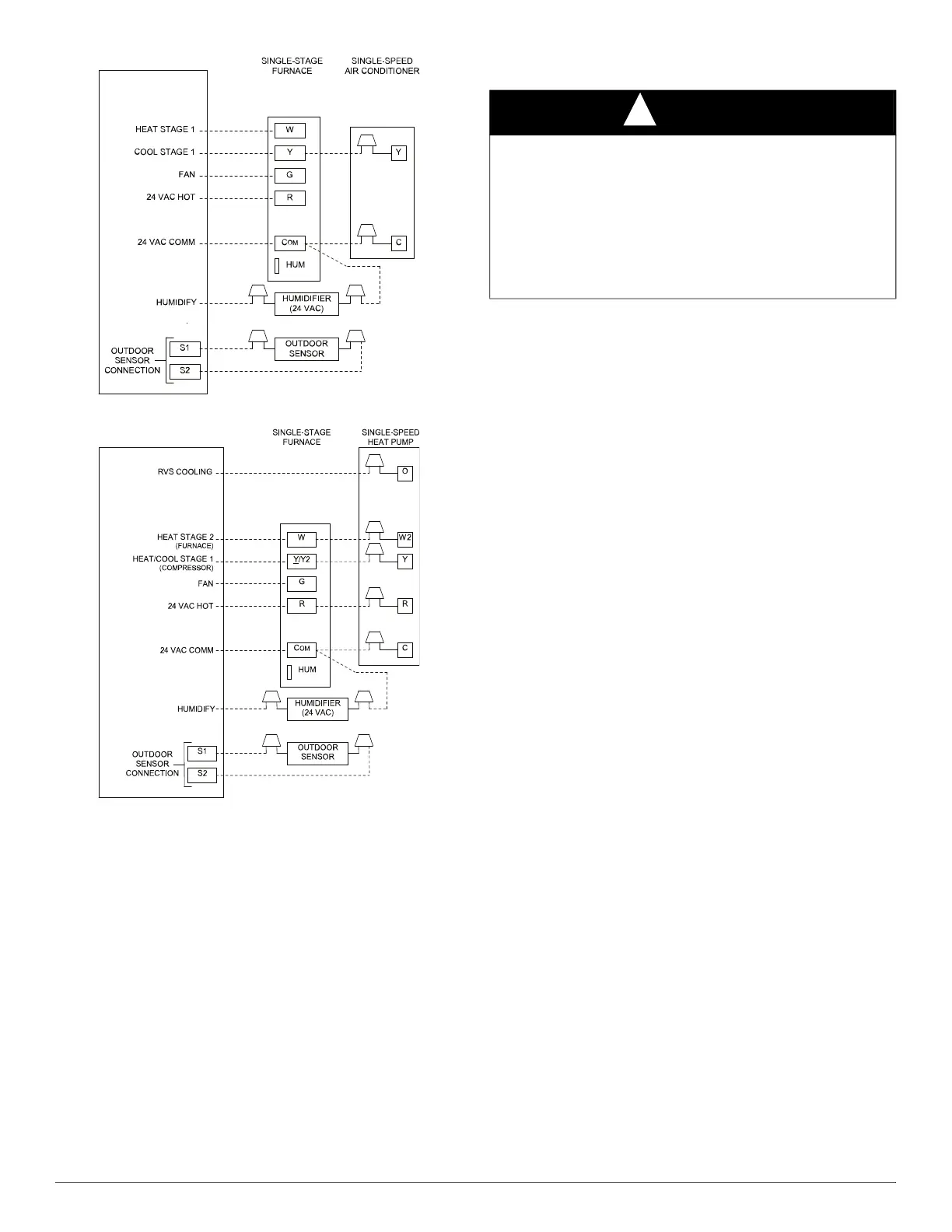

Fig. 38 – Thermostat Wiring Diagrams for Single Stage Furnace

with Single-Speed A/C & Heat Pump

Notes for thermostat wiring diagrams:

1. Thermostat output signals may vary. Consult thermostat installation

instructions for more information.

2. Refer to outdoor equipment Installation Instructions for additional

information and setup procedure.

3. Configure the thermostat for air conditioner installations. Refer to

thermostat instructions.

4. Configure thermostat for dual fuel operation. Refer to thermostat

instructions.

5. Heat pump MUST have a high-pressure switch for dual fuel

applications.

6. For Single-stage AC or HP, configure thermostat for single-stage

compressor operation. Refer to thermostat instructions.

7. NO connection should be made to the furnace HUM terminal when

utilizing the thermostat’s 24-volt humidifier output.

8. Thermostat terminal connection order on furnace control may vary-

reference furnace control labeling for designations

VENTING

NOTE: Planning for the venting system should be done in conjunction

with planning for the ductwork, drainage, and furnace accessories, such

as air cleaners and humidifiers. Begin assembling the venting system

AFTER the furnace is set in place in the required orientation.

Venting for this furnace shall follow all Local codes for Category IV

venting systems. This furnace is CSA approved for venting with

PVC/ABS DWV venting systems. This furnace is also CSA approved

for venting with M&G DuraVentRPolyProR or Centrotherm InnoflueR

polypropylene venting systems using single wall straight and flex, and

required fittings (elbows, reducers, increasers, connectors, adapters)

only.

NOTE: THESE INSTRUCTIONS DO NOT CONTAIN DETAILED

INSTALLATION INSTRUCTIONS FOR POLYPROPYLENE

VENTING SYSTEMS. Refer to the polypropylene venting system

manufacturer’s installation instructions for the polypropylene venting

system installation.

NOTE: When using polypropylene venting systems, all venting

materials used, including the vent terminations, must be from the same

manufacturer.

Special Venting Requirements for Installations in

Canada

Installation in Canada must conform to the requirements of CSA B149

code. Vent systems must be composed of pipe, fittings, cements, and

primers listed to ULC S636. The special vent fittings, accessory

concentric vent termination kits, (KGAVT0701CVT or

KGAVT0801CVT) and accessory external drain trap available from the

furnace manufacturer have been certified to ULC S636 for use with

those Royal Pipe and IPEX PVC vent components which have been

certified to this standard. In Canada, the primer and cement must be of

the same manufacturer as the vent system – GVS-65 Primer (Purple) for

Royal Pipe or IPEX System 636, PVC/CPVC Primer, Purple Violet for

Flue Gas Venting and GVS-65 PVC Solvent Cement for Royal Pipe or

IPEX System 636

(1)

t, PVC Cement for Flue Gas Venting, rated Class

IIA, 65 deg C. must be used with this venting system - do not mix

primers and cements from one manufacturer with a vent system from a

different manufacturer. Follow the manufacturers instructions in the use

of primer and cement and never use primer or cement beyond its

expiration date.

The safe operation, as defined by ULC S636, of the vent system is based

on following these installation instructions, the vent system

manufacturers installation instructions, and proper use of primer and

cement. All fire stop and roof flashing used with this system must be UL

listed material. Acceptability under Canadian standard CAN/CSA B149

is dependent upon full compliance with all installation instructions.

Under this standard, it is recommended that the vent system be checked

once a year by qualified service personnel.

THERMOSTAT

See notes 1, 2, 3, 6, 7 and 8

Single-Stage Furnace with Single-Speed Air Conditioner

NOTE 7

THERMOSTAT

See notes 1, 2, 3, 4, 5, 6, 7 and 8

Single-Stage Furnace with Single-Speed Heat Pump

NOTE 7

NOTICE

!

OPTIONAL VENTING BELOW THE FURNACE

The venting system may be positioned below the furnace ONLY IF the

factory accessory External Vent Trap Kit is used. The External Vent

Trap Kit is only approved for PVC/ABS DWV venting systems.

CAREFULLY FOLLOW THE INSTRUCTIONS PROVIDED

WITH THE EXTERNAL VENT TRAP KIT FOR LAYING OUT

THE VENTING SYSTEM AND THE DRAIN SYSTEM. The

instructions included with this furnace DO NOT APPLY to vent

systems that are located below the furnace.

Loading...

Loading...