PG96MSA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

54

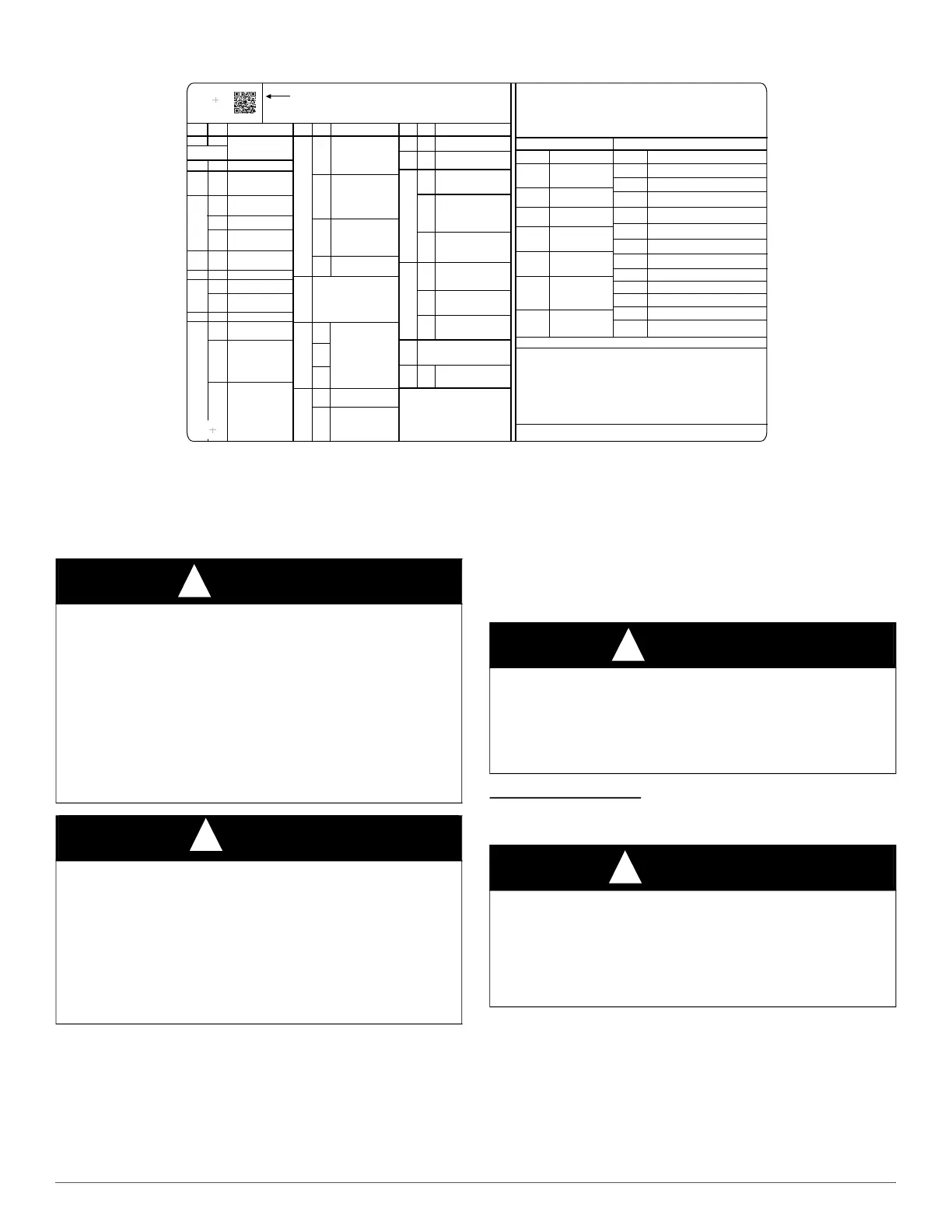

SERVICE LABEL

A210798

Fig. 59 – Service Label Information

START-UP, ADJUSTMENT, AND SAFETY

CHECK

General

1. Maintain 115-V wiring and ground. Improper polarity will result in

rapid flashing control diagnostic light and Status code (10.1) is

displayed. The furnace will NOT operate.

2. Make thermostat wire connections at the 24-V terminal block on

the furnace control. Failure to make proper connections will result

in improper operation.

3. Gas supply pressure to the furnace must be greater than 4.5-in. w.c.

(0.16 psig) but not exceed 14-in. w.c. (0.5 psig).

4. Check all manual-reset switches for continuity.

5. Natural gas service pressure must not exceed 0.5 psig (14- in. w.c.,

350 Pa), but must be no less than 0.16 psig (4.5-in. w.c., 1125 Pa).

6. Blower door must be in place to complete 115-V electrical circuit

and supply power to the furnace components.

Start-Up Procedures

1. Purge gas lines after all connections have been made.

2. Check gas lines for leaks.

3. To Begin Component Self-Test

a. Remove thermostat wire connected to R terminal on control to

ensure no thermostat demands are present.

b. Temporarily depress blower door switch to power the control

board to complete component self-test.

Flt

Last 7 faults that occured

CL

Cooling and Heat Pump Blower speed

CFn

Continuous Fan speed

Hod

Heat OFF delay

Cod

Cool OFF delay

Orientation upflow or downflow

inF

Ct

r5t

Dir

tnn

Twinning Main or Secondary

Program # and Software version

Component test

Ht

Heating Blower speed

Major Minor

Description

Description

Description

Major Minor

Major Minor

1

12

L1 polarity fault

W on at power up

Rapid flash

LED

1

10

1

13

Limit Lockout -

switch open longer

than 3 minutes in

Main Limit circuit

1

33

A switch has opened in

the Main Limit circuit.

34

Ignition fault - during

four consecutive

ignition trials.

2

After successful

ignition (flame proven)

flame loss before

heating blower on

delay.

After successful

ignition (flame proven)

flame loss after heating

blower on delay.

3

45

46

1

Control failure – flame

circuit fault, memory

mismatch or sequence

error.

2

Control failure – gas

valve relay will not

close.

3

1

Control failure

– EEPROM memory

issue.

For code 45, cycle power, if

code 45 repeats, replace

control.

Momentary loss of

power

31

1

21

22

23

False flame

1

Open Main pressure

switch (LPS)

32

1

1

24

Fuse fault

1

27

1

2

3

1

Stuck closed Main

pressure switch

2

Stuck closed

secondary pressure

switch

1

14

Ignition Lockout

after 4 consecutive

ignition tries

2

Flame lost 3 times

after 70s of heating

3

Lockout - 7 loss of

flame events during

a heat request

24VAC sensed on

gas valve when

shouldn’t be

25

No program info in

micro, no heating

operation.

Corrupted program

file, reprogram

control using service

app or super plug

(supplied

separately), no

heating operation.

1

2

Twinned units are

not identical,

program #'s do not

match. Ensure

furnaces are

identical (same

program #)

when twinning.

Main unit will not

operate heating.

3

4

5

6

7

Installer settings

corrupted.Try

reselecting installer

settings, or reprogram

control. Control will

operate using default

installer settings.

Wrong program for

control used -

reprogram control so

program matches

control used. No

heating operation.

Non-Condensing

program detected in

a Condensing model.

Program in super

plug is missing, not

recognized, or

corrupted. Remove

super plug then

retry. If still have 27

code, try a different

super plug. If still

fails, replace control.

If program in furnace control

is missing, not recognized,

or corrupted. Reprogram

Reprogram control with

correct program # as listed

on the rating plate.Replace

control if issue remains.

Main program invalid,

using backup program

to operate. Reprogram

control to correct

issue. Control still

operates normally.

2

Open secondary

pressure switch (HPS)

3

Secondary PS

Lockout - failed to

close secondary

PS after three trials

25

To initiate the component test sequence, the control must be in (idl) mode. No

thermostat demands (W, Y, G). Select component test (Ct) from menu select

buttons to start the component test sequence. Once initiated the furnace control

will perform the following sequence:

1. PUr- Inducer ON (remains ON for test).

2. HSI- After waiting 10s, HSI ON for 15 seconds.

3. Fn- After HSI, then Blower ON for 10 seconds.

4. End- After Blower, Inducer ON for 10 more

seconds.

The test ends.

COMPONENT TEST

MAIN MENU

All copyrighted materials used herein are the property of their

respective owners.

DISPLAY

DESCRIPTION

DISPLAY

DESCRIPTION

STATUS CODE TABLE

Scan QR code or reference troubleshooting guide in installation manual.

SYSTEM STATUS

CFn

bLr

Continuous Fan

Mode

Heat Pump Defrost

Mode

HPd

Cooling Mode

CL

Heating Mode

HT

Idle / Stand by

Mode

iDL

Active Status Code

Secondary Unit

Operating Blower

during CFn, CL,

or HT

##.#

MENU NAVIGATION

Scroll through main menu by pressing the MENU/SELECT button.

Press NEXT/OPTION button to view current setting (will flash on

display) and to scroll through setting options. Press

MENU/SELECT button to save new setting and return to main

menu. The display will flash to confirm setting selection before

returning to the main menu.

The major status code is displayed in the first 2 digits of the display. The minor status

code is displayed in the third digit . The major status code is also displayed on the

LED indicator through the door with the first digit being the number of short flashes

and the second digit being the number of long flashes.

Reset All Installer Settings to

Factory Defaults

idL,Ht,…

Current System Status

CAUTION

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit operation

or performance dissatisfaction.

These furnaces are equipped with a manual reset limit switch in burner

assembly. This switch opens and shuts off power to the gas valve is an

overheat condition (flame rollout) occurs in the burner

assembly/enclosure. Correct inadequate combustion-air supply,

improper gas pressure setting, improper burner or gas orifice

positioning or improper venting condition before resetting switch. DO

NOT jumper this switch.

NOTICE

!

IMPORTANT INSTALLATION AND START-UP PROCEDURES

Failure to follow this procedure may result in a nuisance smoke or odor

complaint.

The manifold pressure, gas rate by meter clocking, temperature rise and

operation must be checked after installation. Minor smoke and odor

may be present temporarily after start-up from the manufacturing

process. Some occupants are more sensitive to this minor smoke and

odor. It is recommended that doors and windows be open during the

first heat cycle.

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing, safety glasses and gloves when

handling parts and servicing furnaces.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury, or death.

Blower access door switch opens 115-V power to control. No

component operation can occur unless switch is closed. Caution must

be taken. Do not touch uninsulated electrical components when

manually closing this switch for service purposes.

Loading...

Loading...