6

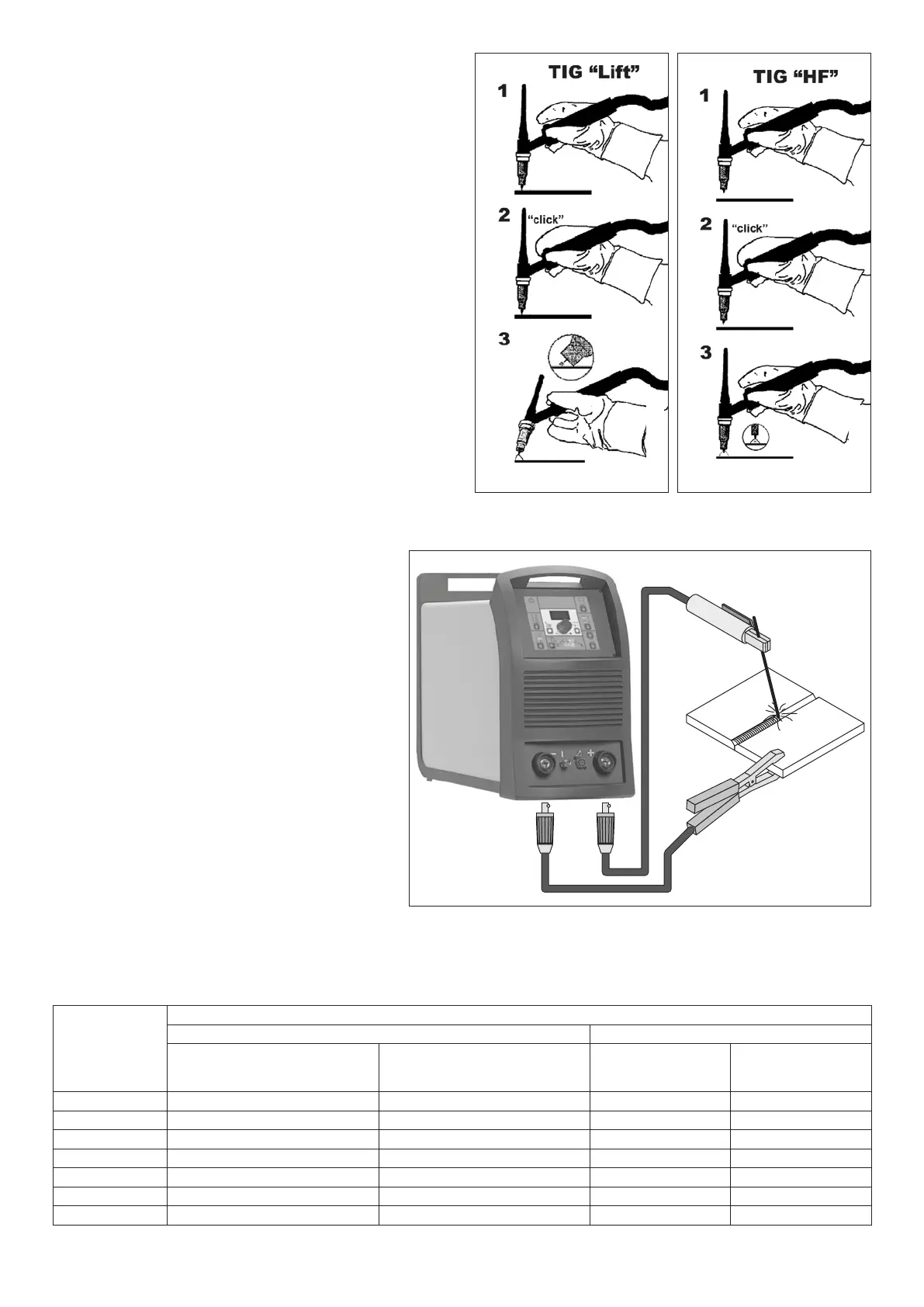

TIG WELDING WITH “Lift” TYPE STRIKING

4a) Open the gas cylinder and flow regulator.

5a) Put the electrode at the point at which welding is to begin,

put the TIG torch at an angle so that the edge of the gas

nozzle is not on top of the piece to be welded, keeping con-

tact between the point of the electrode and the piece to be

welded (Fig. E-1).

6a) Press the torch button.

7a) The “Lift” function strikes the arc when the TIG torch elec-

trode comes into contact with the workpiece and is then

removed (Fig. E-2)

8a) Carry out TIG welding (Fig. E-3).

To end welding:

•

Lift the torch slowly, at a certain point the welding current

decreases, and then stop.

•

The welding machine follows an automatic down slope

along with extinguishing of the arc.

9a) When finished welding remember to shut off the gas cylin-

der.

TIG WELDING WITH HIGH FREQUENCY STRIKING (HF)

4b) Open the gas cylinder and flow regulator.

5b) Put the electrode at the point at which welding is to begin,

put the TIG torch at an angle so that the edge of the gas

nozzle is not on top of the piece to be welded, keeping a

2-3 mm gap between the point of the electrode and the

piece to be welded (Fig. F-1).

6b) Press the torch button.

7b) The voltaic arc strikes even without contact between the

TIG torch electrode and the workpiece (Fig. F-2).

8b) To continue welding put the torch back in its normal posi-

tion (Fig. F-3).

IMPORTANT: The high frequency switches off auto-

matically after switching on.

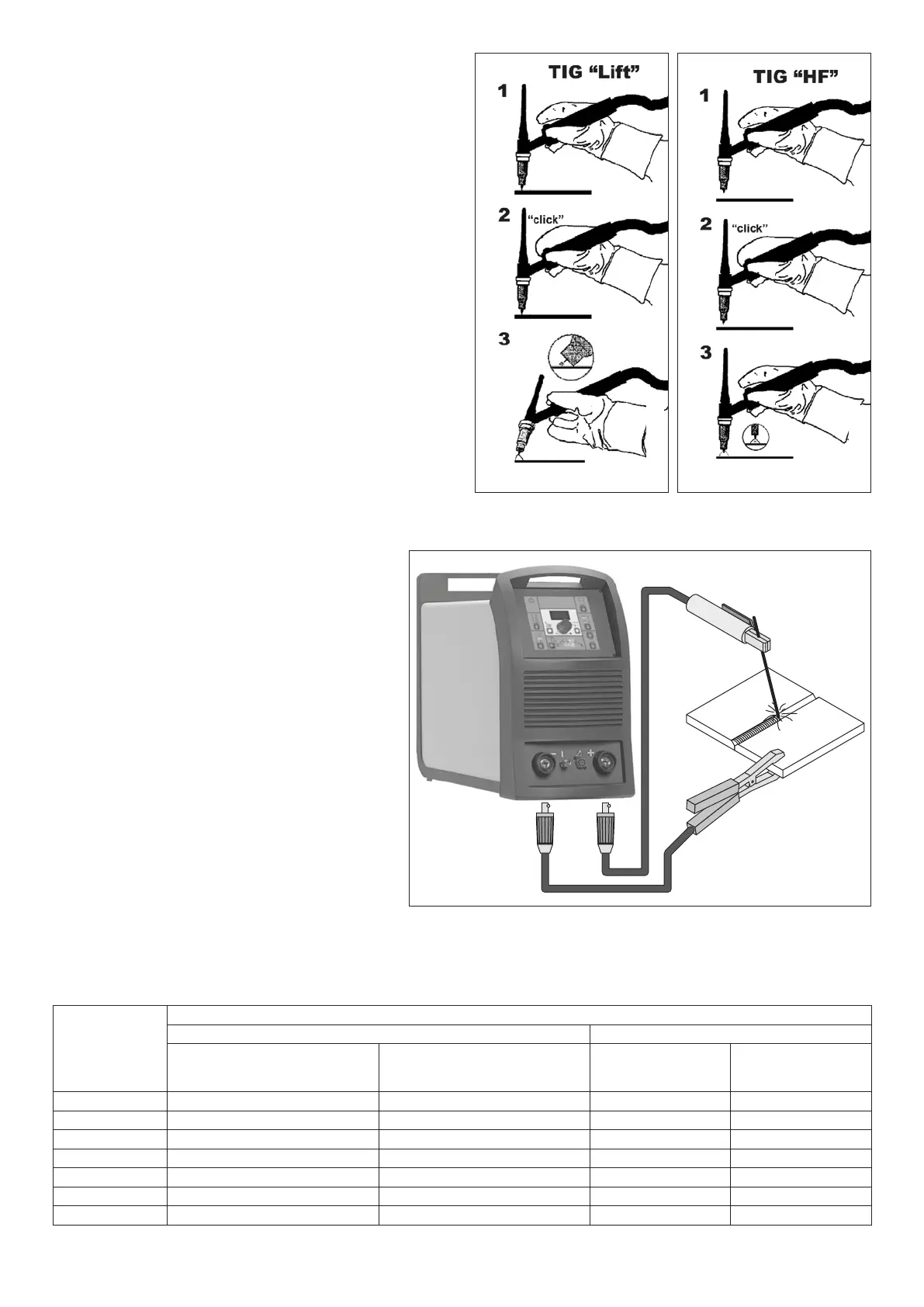

PART TO BE WELDED

The part to be welded must always be connected to

ground in order to reduce electromagnetic emission.

Much attention must be afforded so that the ground

connection of the part to be welded does not increase

the risk of accident to the user or the risk of damage

to other electric equipment. When it is necessary to

connect the part to be welded to ground, you should

make a direct connection between the part and the

ground shaft. In those countries in which such a con-

nection is not allowed, connect the part to be welded

to ground using suitable capacitors, in compliance

with the national regulations.

WELDING PARAMETERS

Table 3 shows the currents to use with the respective

electrodes for TIG AC and DC welding. This input is

not absolute but is for your guidance only; read the

electrode manufacturers’ instructions for a specific

choice. The diameter of the electrode to use is direct-

ly proportional to the current being used for welding.

2000HA73

2000HA72

FIG. E FIG. F

FIG. G

2000H809

Table 3

Ø ELECTRODE

(mm)

ELECTRODE TYPE - Current adjustment field (A)

TIG DC TIG AC

Tungsten

Ce 1%

Grey

Tungsten

Rare ground 2%

Turchoise

Tungsten

Pure

Green

Tungsten

Rare ground 2%

Turchoise

1 10-50 10-50 - -

1,6 50-80 50-80 30-60 30-60

2,4 80-150 80-150 60-120 60-120

3,2 150-250 150-250 80-160 80-160

4 200-400 200-400 100-240 100-240

4,8 - - 200-300 200-300

6,4 - - 275-400 275-400

Loading...

Loading...