4-43

0

1

2

3

4

3

6

7

8

9

10

11

12

13

14

15

16

17

18

4B THERMIC MOT KO

Condition for error detection

Interrupted or disconnected motor temperature sensor.

Verify:

- The state of the wiring harness and the temperature sensor connector

- Connect a 600 ohm resistance to the sensor connector:

• If the alarm disappears, replace the temperature sensor

If the alarm persists replace the logic unit.

4C ENCODER LOCK

Condition for error detection

Interrupted or disconnected motor encoder.

The alarm appears after 10 seconds approximately with the accelerator pedal pressed.

The machine works at reduced speed and at maximum current.

• Disconnect the pump from the motor and see if the motor runs freely

• Check the state of the pump motor encoder

4D UNUSED

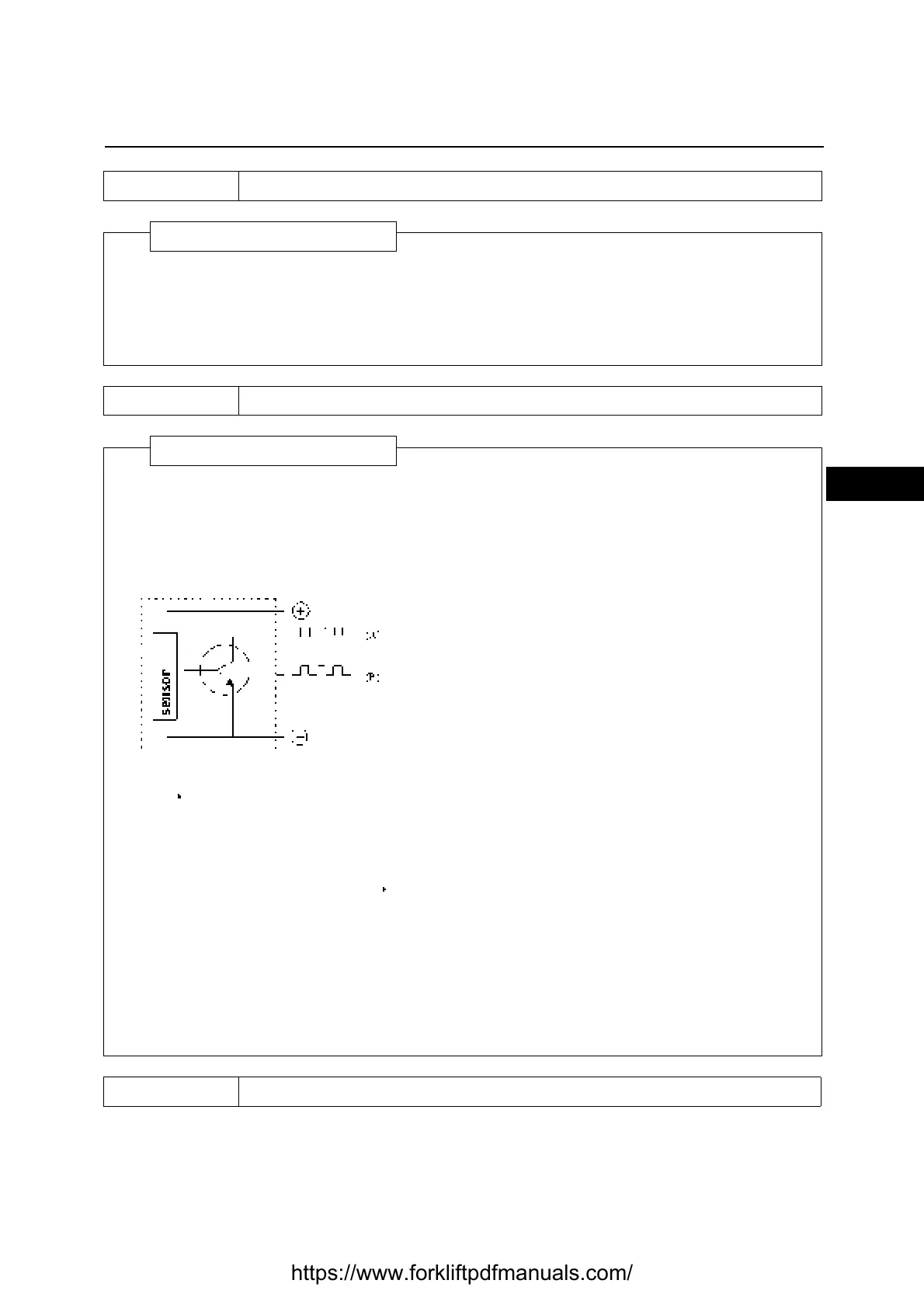

Encoder basic electric diagram.

In the figure there is only one signal (A).

The encoders used generate two equal signals,

with a 90° difference (A-B).

1. Connect the tester positive point (red) to the

encoder positive terminal.

2. Connect the tester COM point (black) to the

encoder signal (A).

According to the engine position, the following

values will be displayed:

• low signal: 0.5 -- 1.5 Volt

• high signal: 10.5 -- 11.5 Volt

Intermediate values cannot be read as the motor

is stopped.

If the motor is working, the multemeter will

automatically read the Mv (medium value)

Mv= 5,5 - 6,5 Volt

Carrying out this test directly on the logic

connectors it is possible to determine if the

signals are good (see upper description) or if the

channels are opened or in shour circuit. If the

signals are good, the problem should be

attributed to the logic unit.

https://www.forkliftpdfmanuals.com/

Loading...

Loading...