Chapter 5

After-use Care and Maintenance

Edition 1 – December 2019 SAFETY FIRST 123

MSA G1 Electronic Breathing Apparatus

If the facemask and the outside of the demand valve are contaminated with

combustible products it must be cleaned and washed using a mild cleaning

detergent in tepid drinkable quality water, then rinsed thoroughly before

disinfecting in BioGuard

®

.

Do not use any cleaning products that can or might attack any part of the BA.

Do not use alcohol, acetone, trichloroethylene, organic solvents such as

nitrous dilution, spirits, thinners, gasoline or petrol.

Facemasks must be cleaned individually to prevent cross-contamination.

Only totally clean BA components can be effectively disinfected.

Disinfecting the facemask

Step Description Illustration

1 Remove the demand valve from the

facemask.

Check that the nose cup is securely fitted,

ensuring the correct orientation.

Throughout the facemask after-use

maintenance and cleaning process, ensure

that the demand valve remains dry. Rinse the

facemask with fresh water to remove the

majority of particles, waste materials and

contaminants.

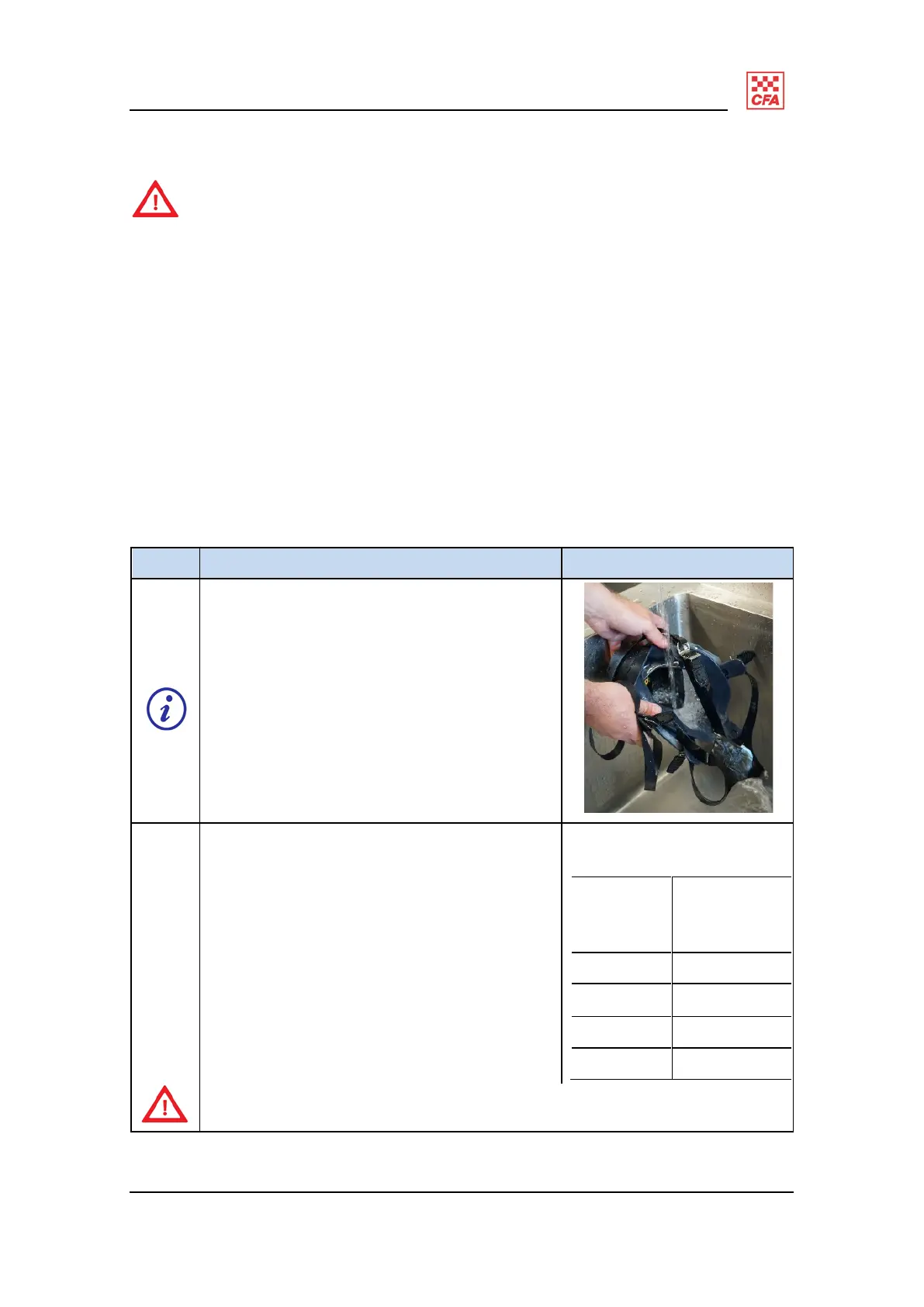

2 Where BioGuard

®

is supplied from State

PPE&C Management Centre, pre-diluted to a

1:3 ratio, further dilution in water is required

before use. See Approved Mixing Rations

under Illustration.

Mix BioGuard® in a suitable and clean vessel

such as a bucket, sink or container.

Completely submerge the mask for 10

minutes. Agitate if possible. Do not

exceed 10 minutes with the facemask

submerged.

Approved BioGuard®

mixing ratios

Fresh

water

BioGuard®

(1:20

solution)

5 ltrs 250 ml

10 ltrs 500 ml

15 ltrs 750 ml

20 ltrs 1000 ml

If agitating, chemical resistant gloves and eye protection must be worn.

Loading...

Loading...