8.

STANDARD ADJUSTMENTS

A

J'

t'

I o;us

mg

timing

tl1e

needle with

Adjusting the height of the

neeclle

<Needle

bar

highest point>

Needle plata

-

18-

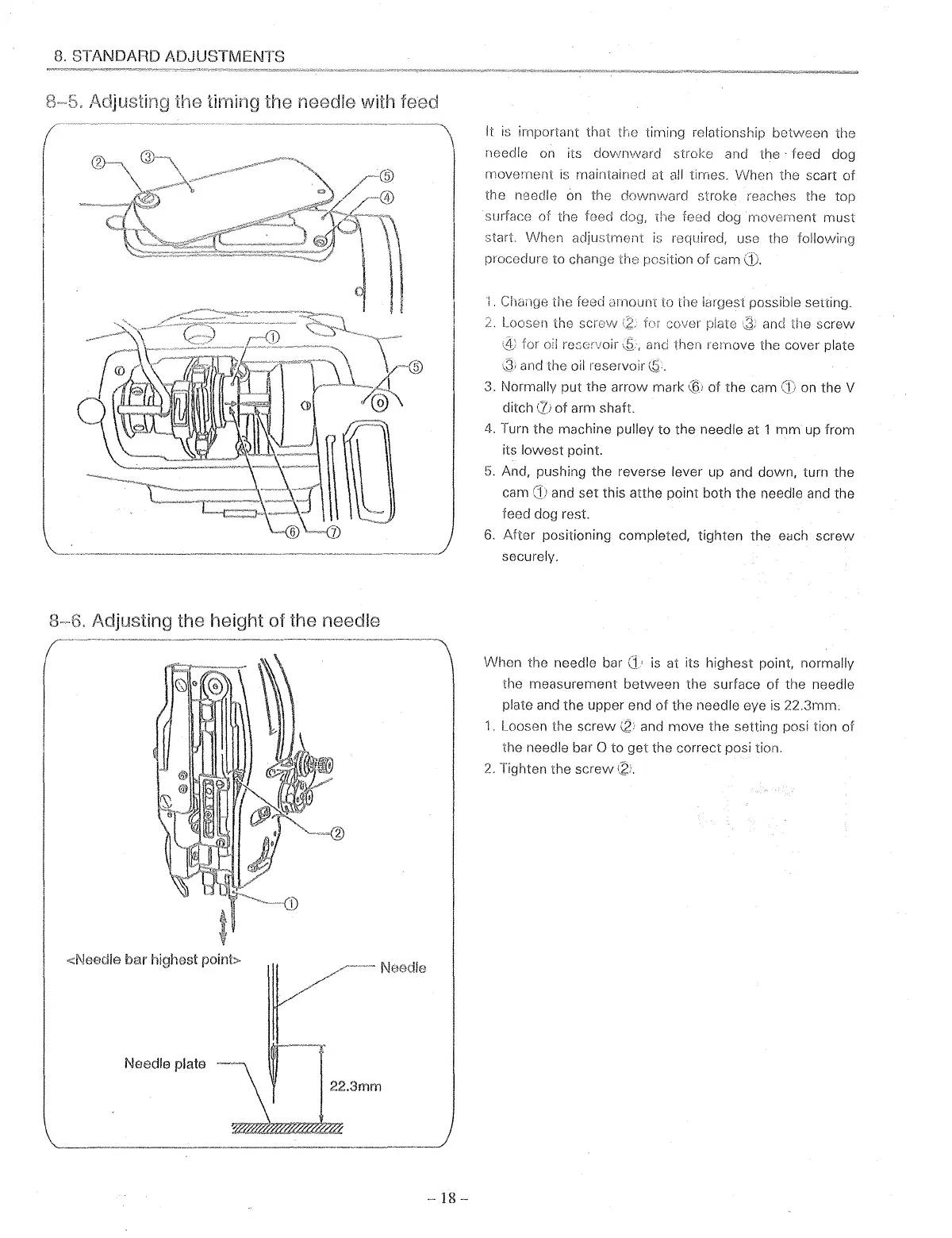

It

is

important that the tirning relationship

between

the

needle on its

downward

stroke and the · feed dog

movement

is

maintained at all tirnes.

When

the scart

of

the

needle on the

downward

stroke reaches the top

rhe feed dog moven1ent

must

start

When

use the following

procedure to change

the

1.

Clla:1ge the feed

amoum

to the largest possible setting.

2.

Loosen the

screw

for cover

and

the

screw

for oil resc-::voir

Q,

and then l"ernove the cover plate

and the

oil reservoir

3. Normally put the

arrow

mark

'~i

of

the

earn on

the

V

ditch

of

arm

shaft

4.

Turn the machine pulley

to

the

needle at 1

mm

up

from

its

lowest

point.

5.

And, pushing

the

reverse lever up and down, turn

the

cam and

set

this atthe point both

the

needle and the

feed dog

rest

6.

After

positioning completed, tighten the each

screw

securely.

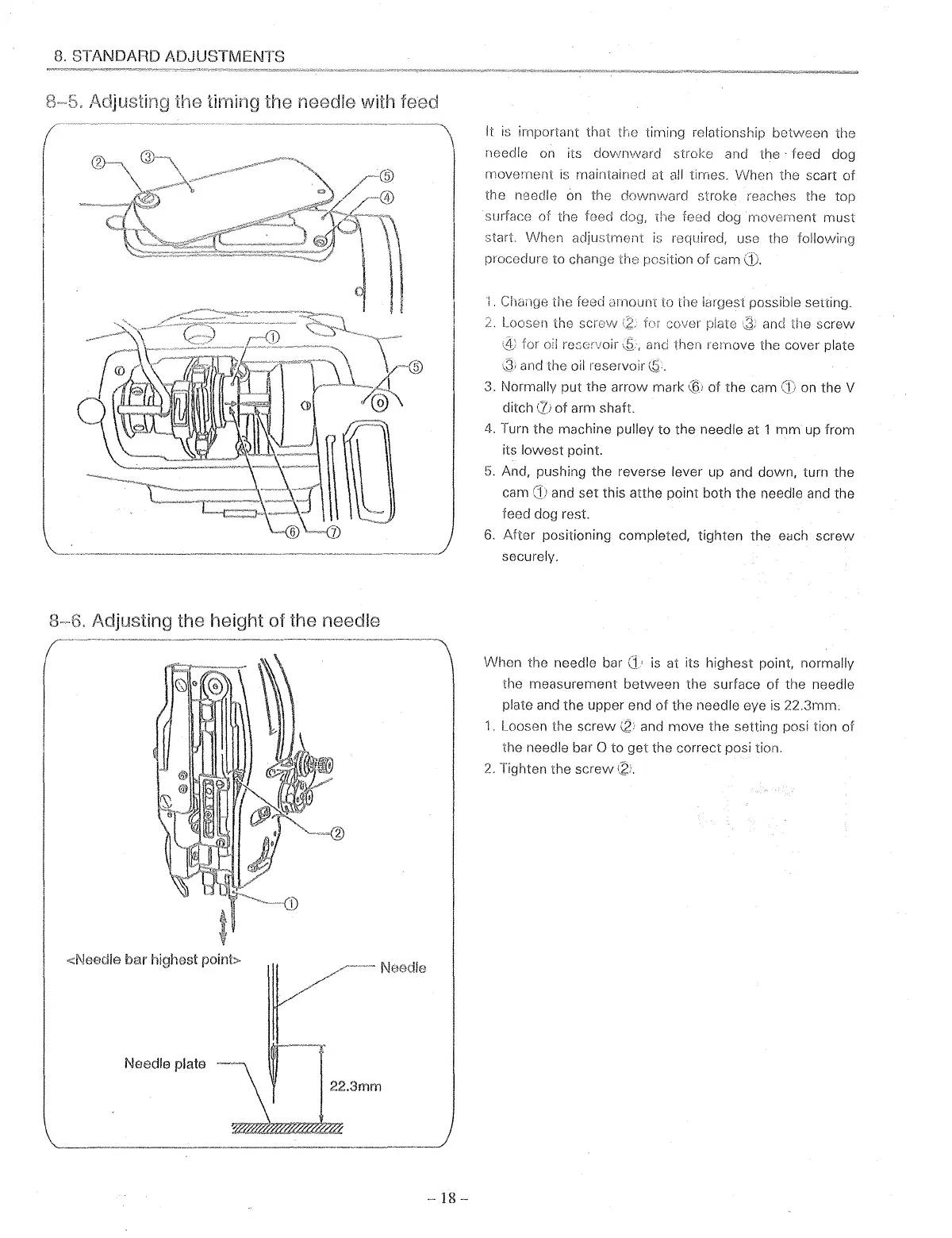

When the needle bar

G.•

is at its highest point, normally

the measurement

between

the

surface

of

the

needle

plate and the upper end

of

the

needle eye is 22.3mm.

1.

Loosen the

screw

\2' and

move

the setting posi tion

of

the needle bar 0

to

get

the correct posi tion.

2.

Tighten the

screw

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...