All Rights Reserved

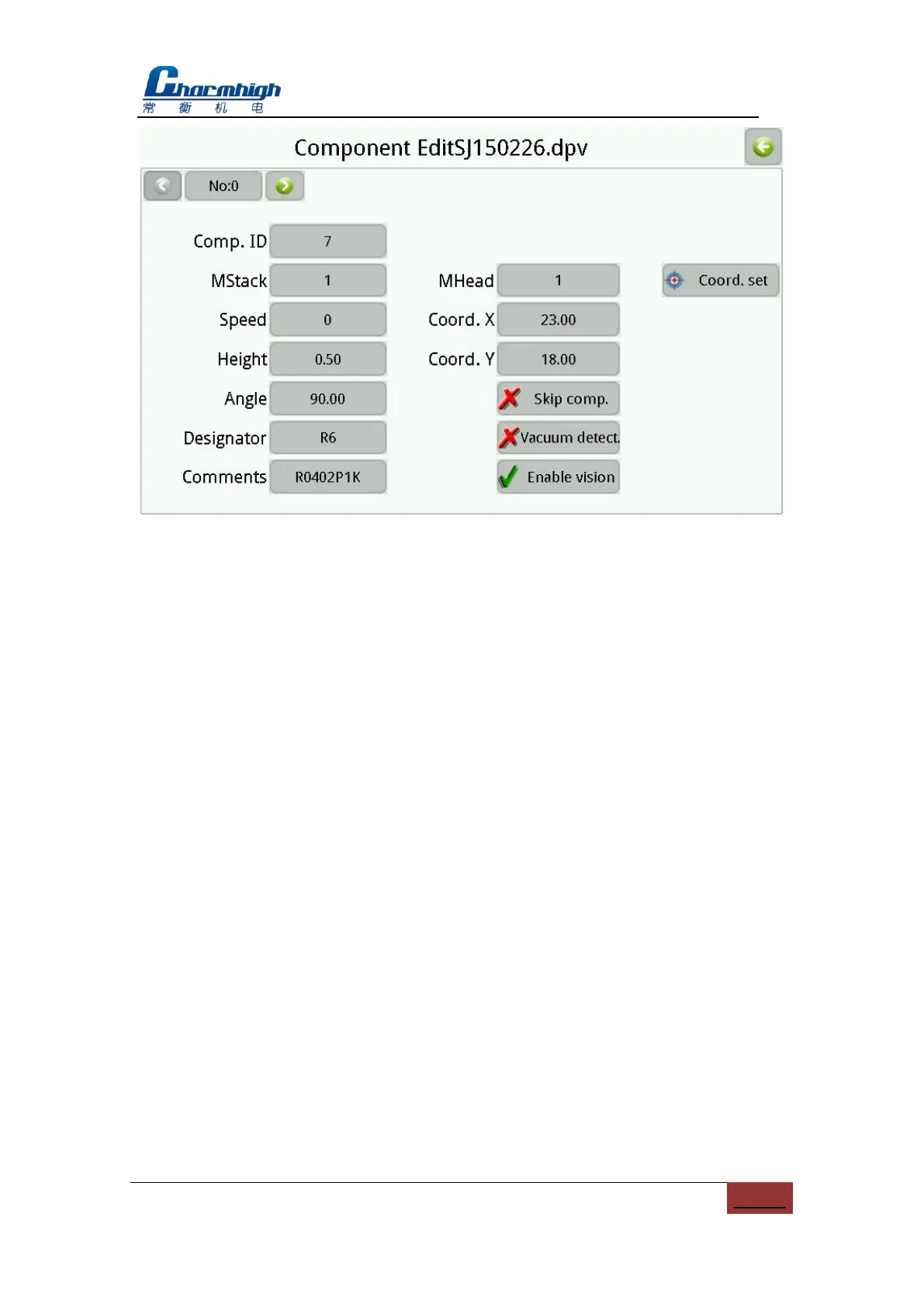

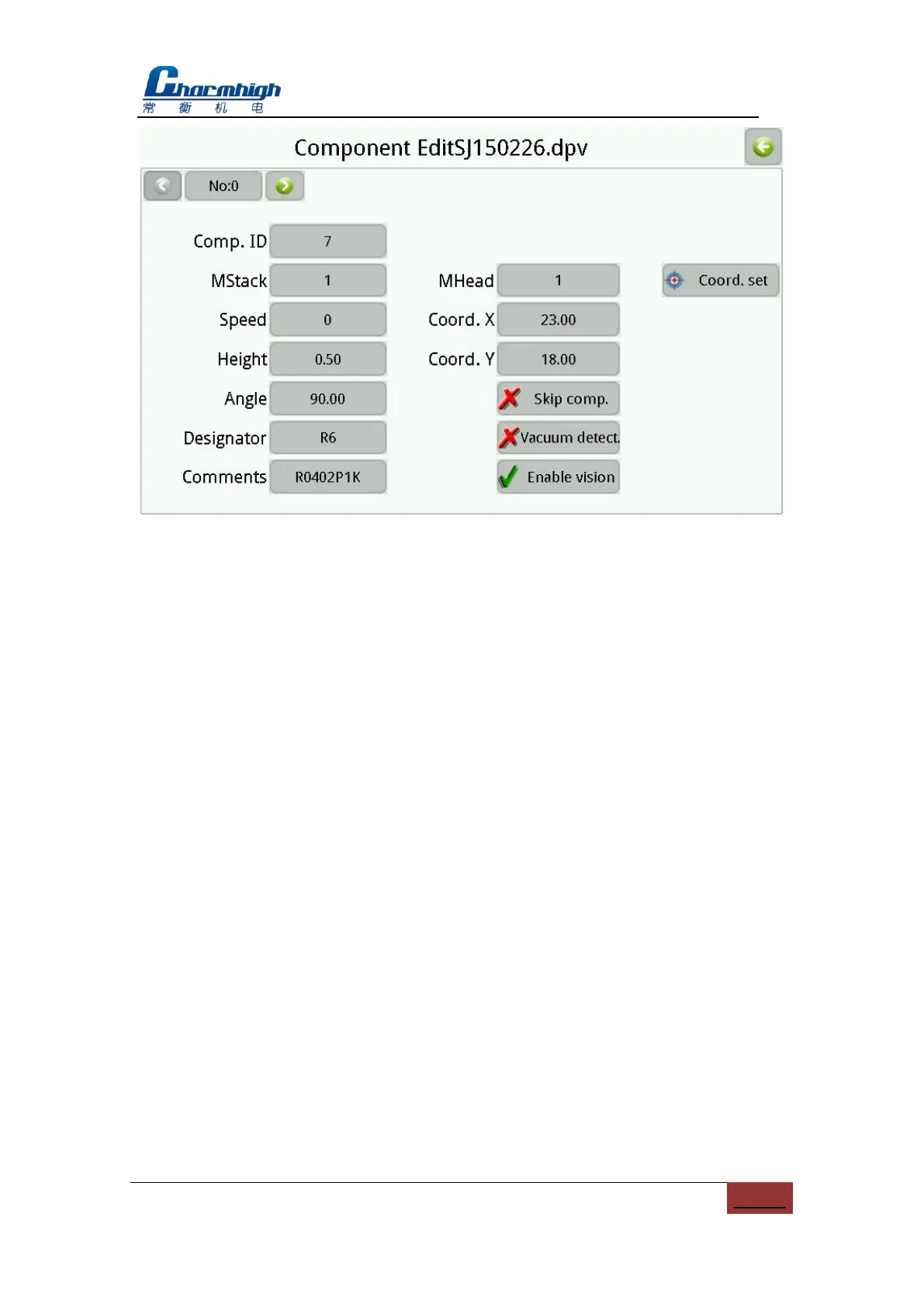

Figure.9-3

(1) Comp. ID: Set component ID number, component ID number can not repeat in

the same work file;

(2) MStack: Set the specified component‟s material stack, when specifying a new

material stack, the material stack list in work file will automatically add a new

similar material stack;

(3) Speed: Set the component speed, set to 0 indicate use system speed, tips,

reduce speed properly when mount IC can improve the accuracy, e.g. 50%;

(4) Height: Set component height, smaller values represent lower height, and the

nozzle down more; Note,in order to adapt the 1.6 mm height PCB board, the

factory default height is 0.5 mm. Do some adjust for different thickness boards.

(5) Angle: Set component rotation angle, counterclockwise is positive, clockwise is

negative;

(6) Designator: Component designate information, such as R1, R2, C1, U1 etc.;

(7) Comments: Component annotation information, such as 0402,0805;

(8) MHead: Select nozzle, e.g. nozzle 1;

(9) Coord. X: Component coordinate X, generally do not need to modify if it is

generated in work file;

(10) Coord. Y: Component coordinate Y, generally do not need to modify if it is

generated in work file;

(11) Skip comp.: Check indicate not mount;

(12) Vacuum detect: Check indicate not throw material due to vacuum insufficient,

Loading...

Loading...