–16 –

Requirements:

1. The thumbpiece must be in the adjustment position(4) (Fig. 6).

2. The material thickness compensator (if existing) must be set to the adjustment

position (Section 5.2)

3. The unit for the material thickness must have been set (Section 4.3)

To perform the calibration procedure:

1. Select a new material or edit an existing one (by re-entering the values) from the

material menu.

2. Enter a designation (you can use the software supplied with the tension meter

alternatively).

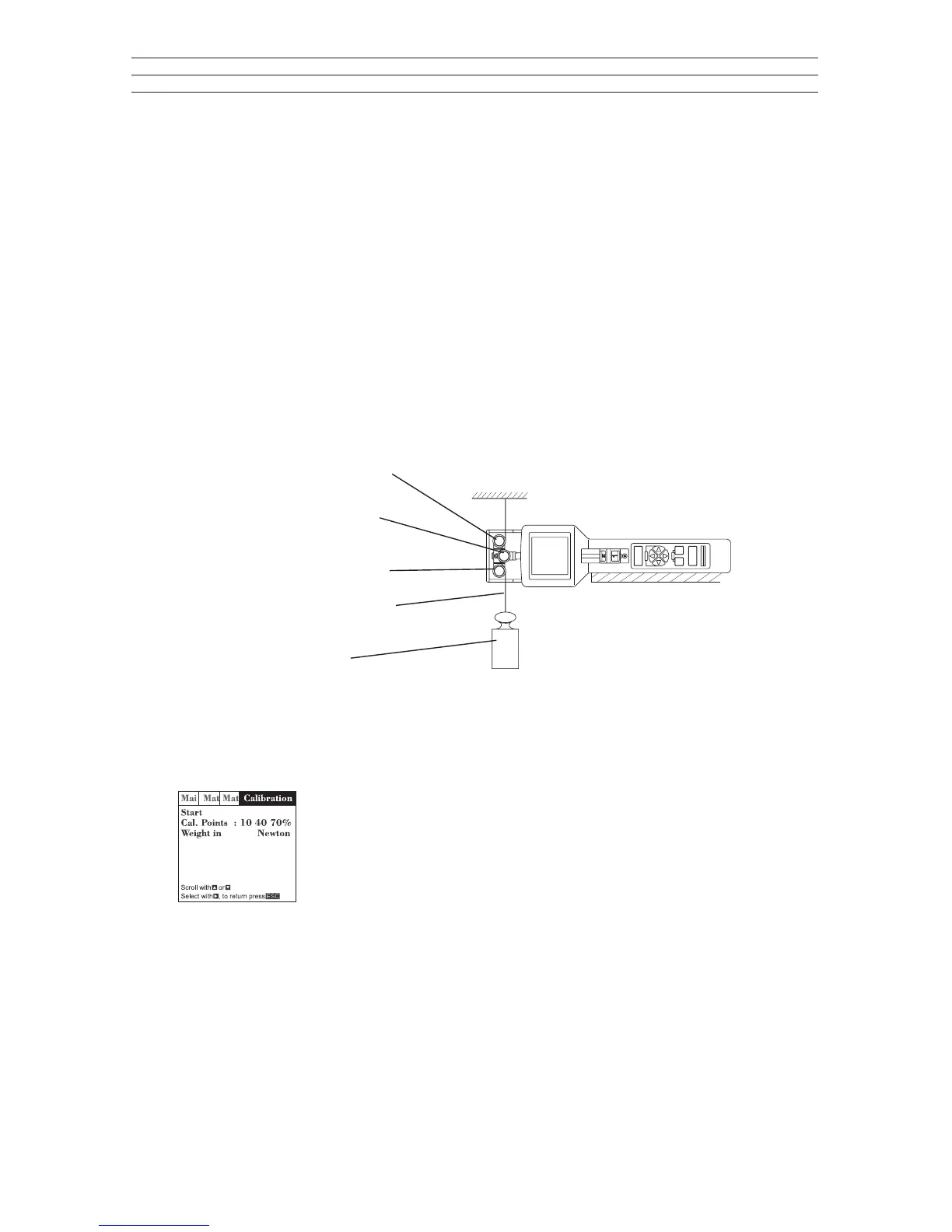

Guide roller

Guide roller

Measuring

Roller

Material to

be measured

Weight

NOTE: While performing the calibration, the tension meter must be xed in such a

way that the material to be measured runs smoothly between the guide rollers and the

measuring roller. The display gives detailed information on the calibration.

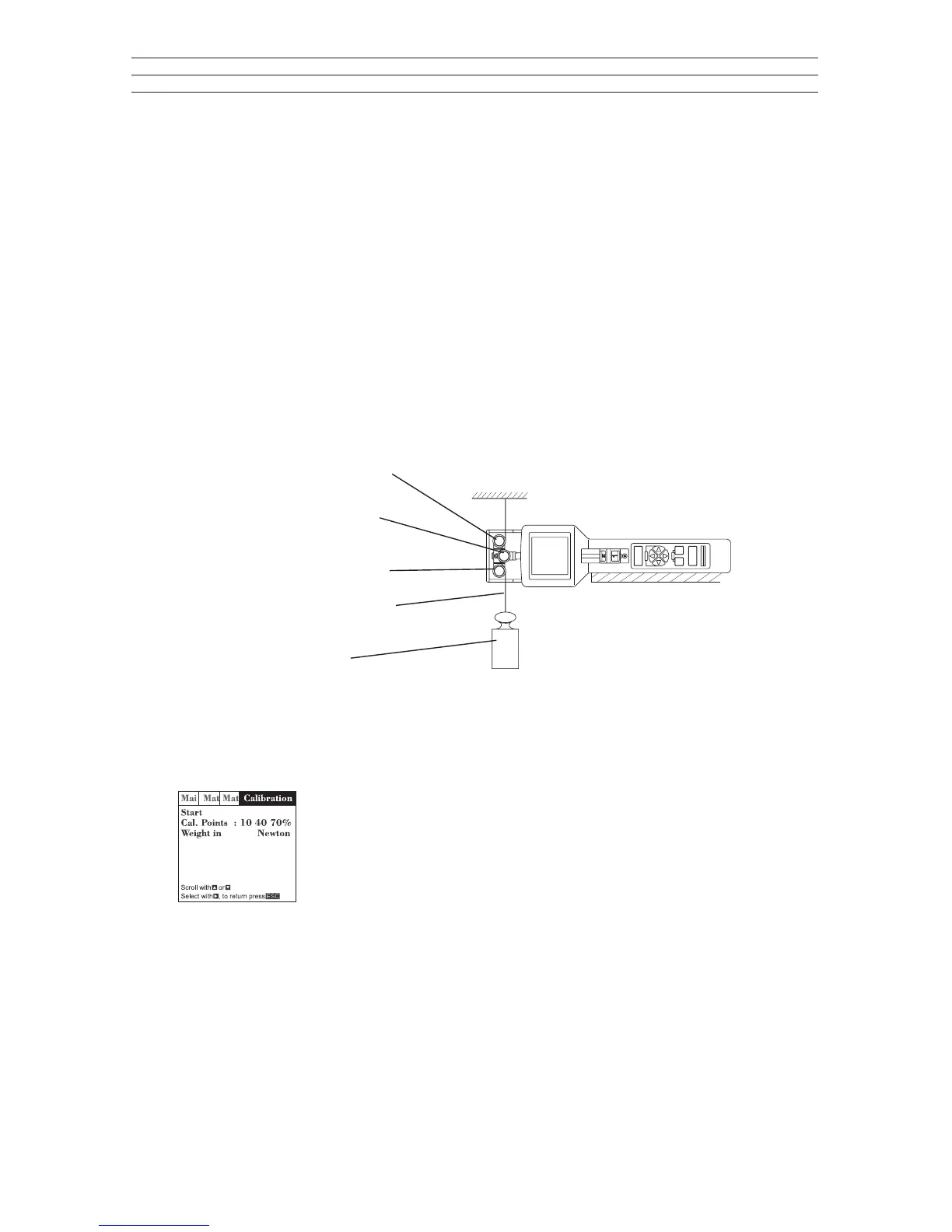

In the Material menu, select Calibration

Step 1:

Set the calibration points and weights, e.g. in Newton using the

calibration points 10%, 50%, and 90% of full scale

Start: Select the Start menu item.

Alternative calibration points:

10%, 40%, 70% 10%, 30%, 60%

10%, 30%, 50% 10%, 20%, 40%

10%, 40%, 90% 10%, 60%, 90%

10%, 60%, 100%

We recommend to use the 10%, 50%, 90% setting for an initial calibration. If the

measured values are not accurate enough when you check the calibration, repeat the

calibration using other calibration points. We recommend that you align the middle of

the tension range to be measured with the middle calibration point.

FIG. 13

Loading...

Loading...