28

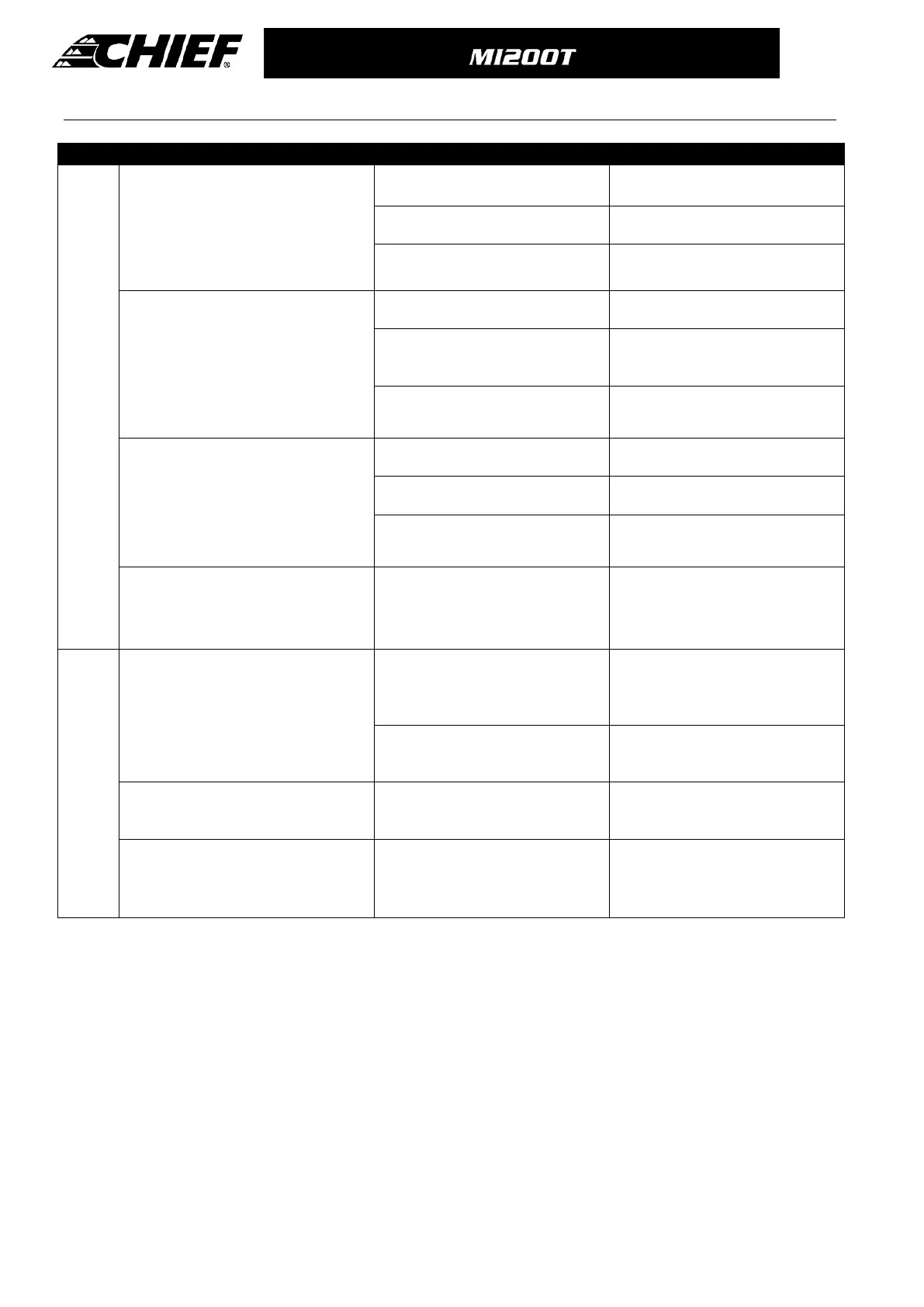

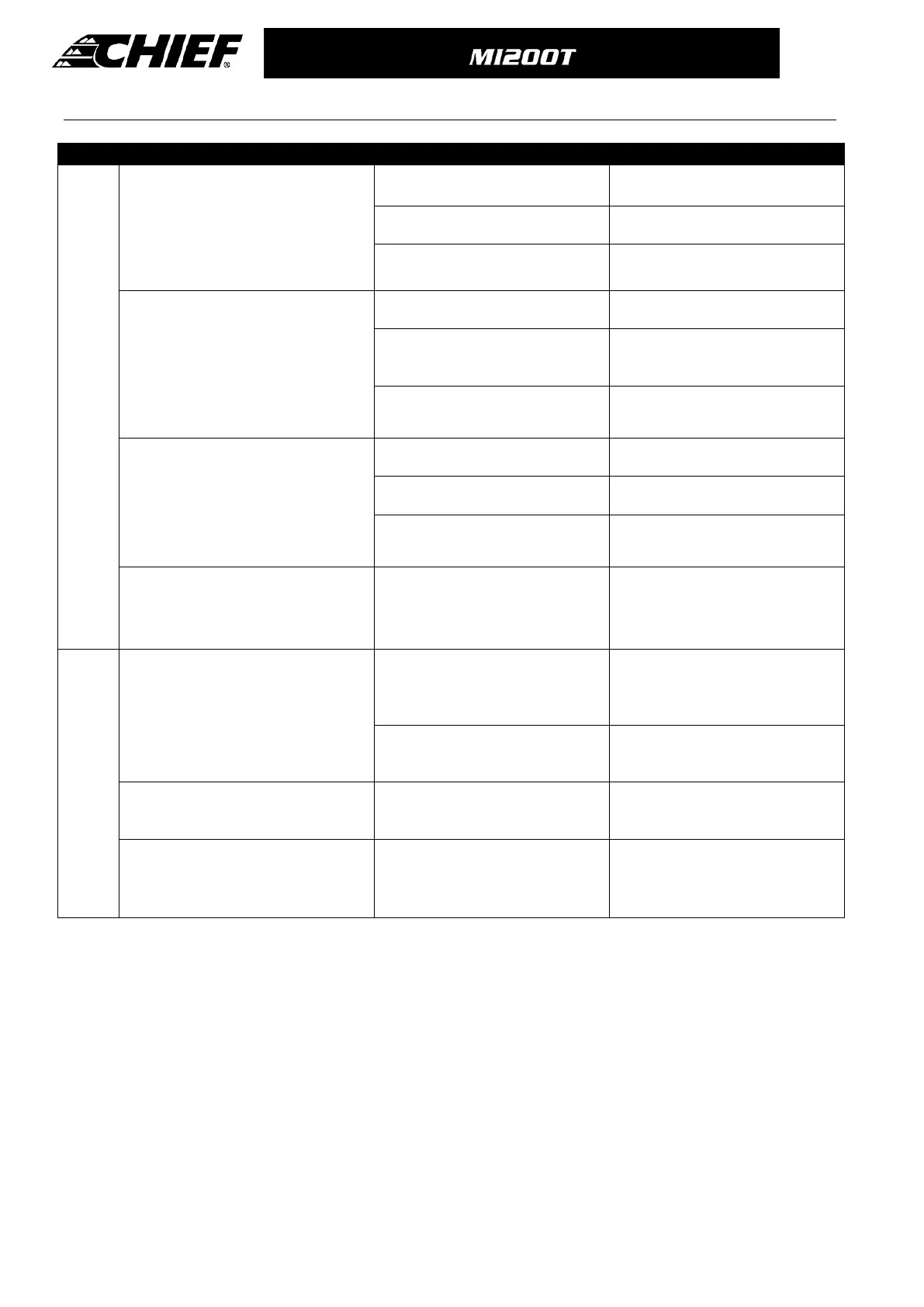

6. SYMPTOMS / REASONS / SOLUTIONS

Clamp

The Spot weld doesn’t hold /

is not good

The caps used are worn

out/faulty

Replace the caps.

Insufficient grinding /

preparation of the workpiece

Sand and clean the metal

sheet again

.

The arm selected doesn’t

match the one installed

Check the arm with the

software

The spotter makes holes in

the steel

The caps used are worn

out/faulty

Replace the caps

Not enough pressure

network

Insufficient preparation of

the work-piece

Sand and clean the metal

sheet again

Lack of power on the clamp

Power supply issue

Check the stability of

voltage delivered

Bad tightening of the C

arm.

Check procedure for

tightening C arm

The caps used are worn

out/faulty

Replace the caps.

Unit overheats quickly /

swelling of the power cable

The arm C badly cooled

Check the connection of the

C Arm to the cooling

section of the clamp

Overheating of the gun

The spot weld made doesn’t

hold

Gun sheath outside the

gun

.

come inside the gun for the

air cooling to cool inside the

Bad tightening of the

mandrel

.

Check the tightening of the

mandrel, the star holder,

and the state of the sheath..

The weld is not good

Bad contact of the earth

clamp

securely connected to the

Lack of power with the gun

Bad contact of the earth

clamp

Check the ground

connection

Loading...

Loading...