5

3. INSTALLATION OF THE MACHINE

Before use

Several checks are necessary before using the unit to ensure good performance of the machine:

- Check the electrical line voltage: it should be between 200 V and 240 V, 3 phases, with a 40 A delayed circuit breaker,

curve D (or aM type

fuse).

- Check the cross section of the cable going from the main electrical board to the socket where the machine will be plugged in

to: it should be 4x10 mm

² (AWG8). If the cable is longer than 10m, use a 10mm² conductor. If you are using an electrical

extension

cord, use a 6 mm² conductor (use 10 mm² if the total length of the electrical line + extension cord is greater than 10 m).

- Connect a 3 phase plug with earth (minimum 40 A) to the power cable.

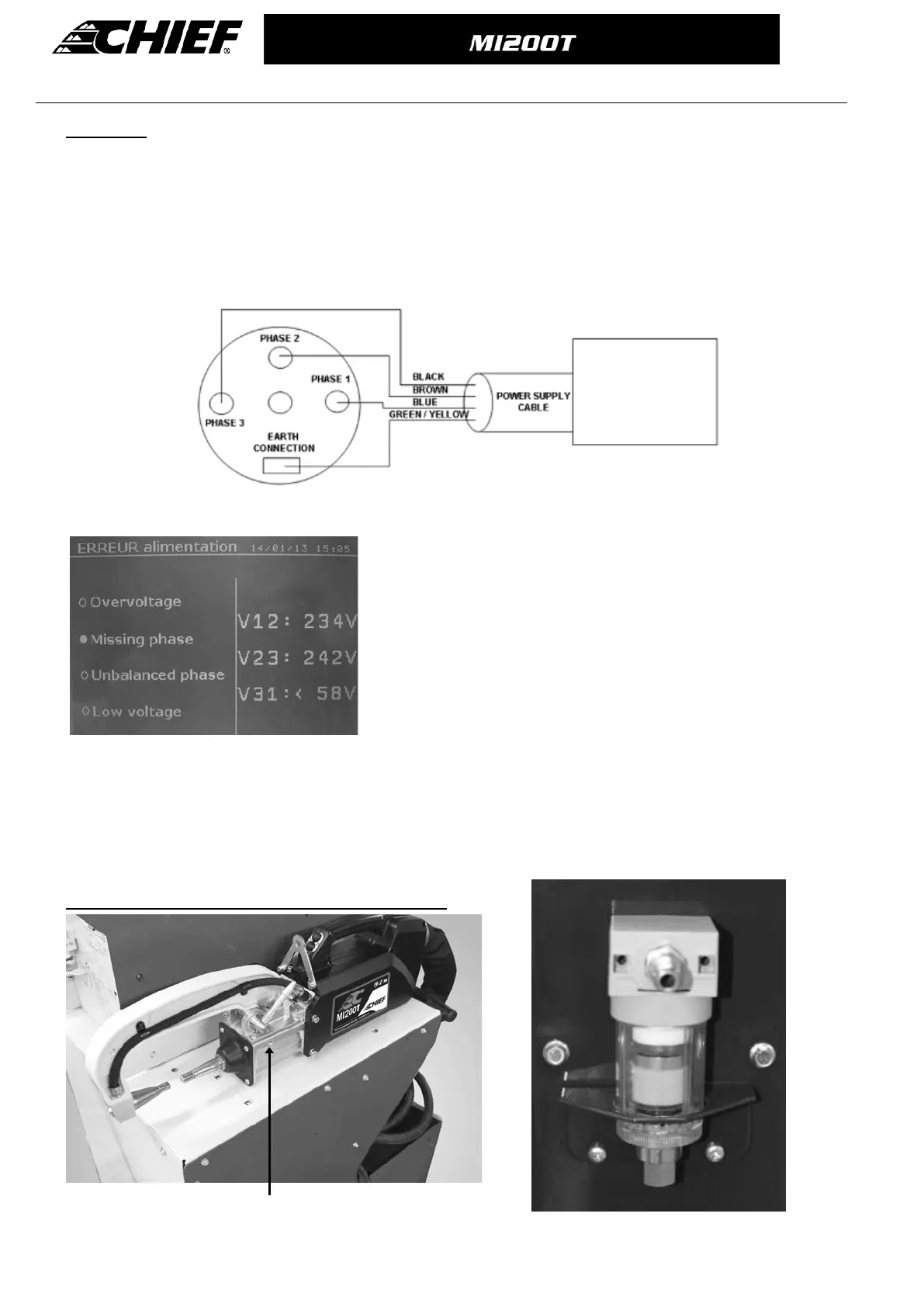

- In case of bad connection or bad voltage on the electrical line, the following screen will appear :

On the right hand side of the screen appears the voltage on each phase.

Overvoltage : the mains voltage lies beyond 268 V rms.

Low voltage : the mains voltage lies below 160 V rms.

Unbalanced phase : one phase has a significantly lower voltage than the

other two.

Missing phase : one phase is not connected properly.

- Caution: in order to avoid voltage drops which can generate bad welding spots, do not overload the electricity supply, do not

use cables with insufficient diameter/cross seciton. Do not use a mains socket that is located too far from the circuit breaker.

- If the machine is not sufficiently powered, it will not be possible to ensure a good quality weld.

- Check that the compressed air network can deliver a minimum of 7 bars (dry air), then connect the compressed air

network to the back of the machine.

The machine must not be used on a compressed air network with a pressure lower to 3 bars.

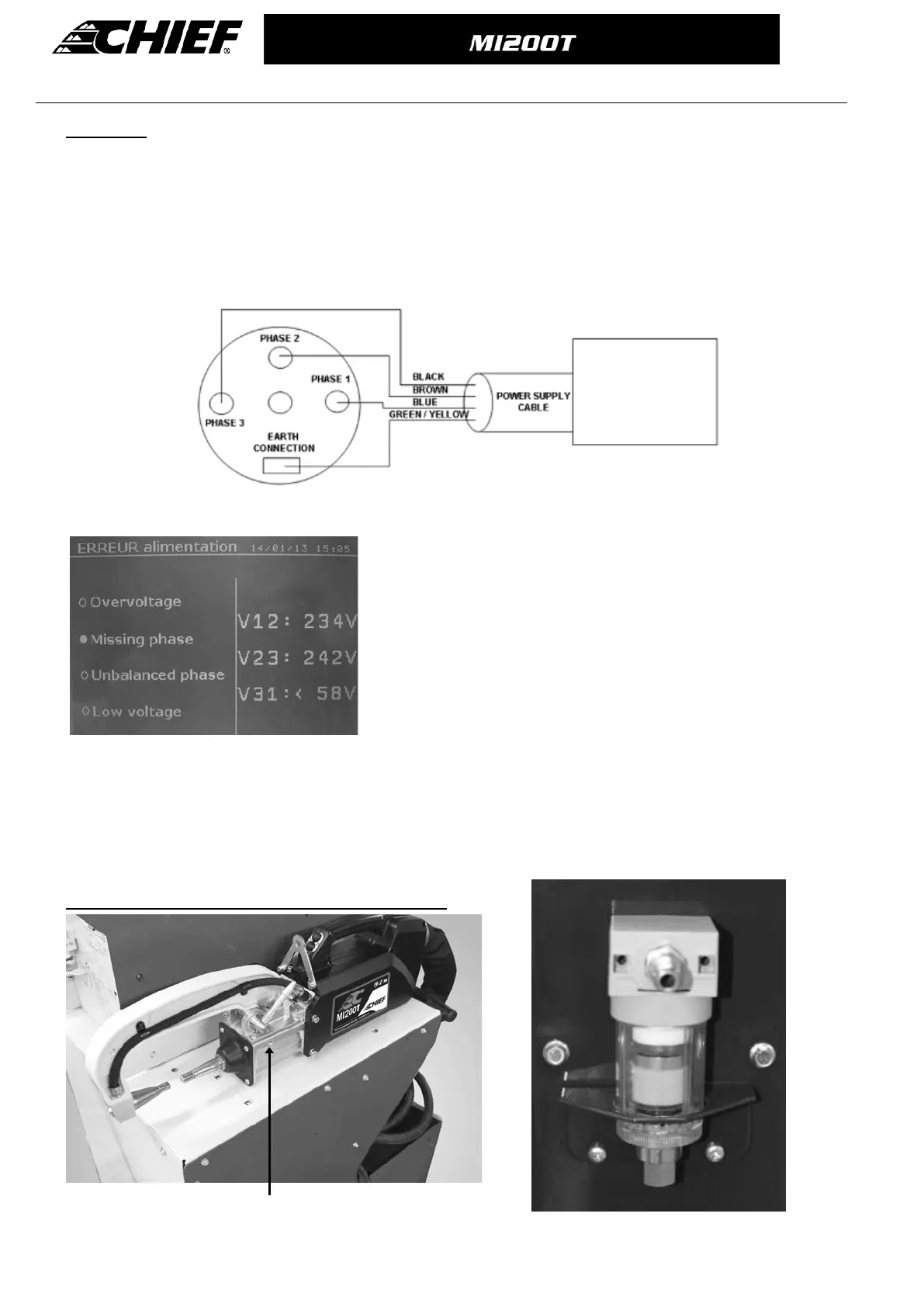

Assembling the clamp handle and the air connector

Assemble the clamp handle on the left side of the clamp

Screw the air connector on the back

of the air filter.

Chief

MI200T

Loading...

Loading...