Pag. 41 a 47 28/02/2023 Nome file: DOC0103 A00

9. BELT CENTERING

9.1 PRELIMINARY OPERATIONS

In order to obtain a precise belt centering, the first thing to do is to verify that the dryer is on level. Use the leveling feet

near the casters to correct any unevenness to the floor. Open the lateral panels and use the frame of the dryer as a

reference.

9.2 LINE-UP THE ROLLERS

To maintain belt centering the belt’s rollers need to be parallel. To achieve this there are 3 registration screws that act

upon the roller supports. The roller support nearest the motor is devoid of such an adjustment so as to avoid altering the

belt tension.

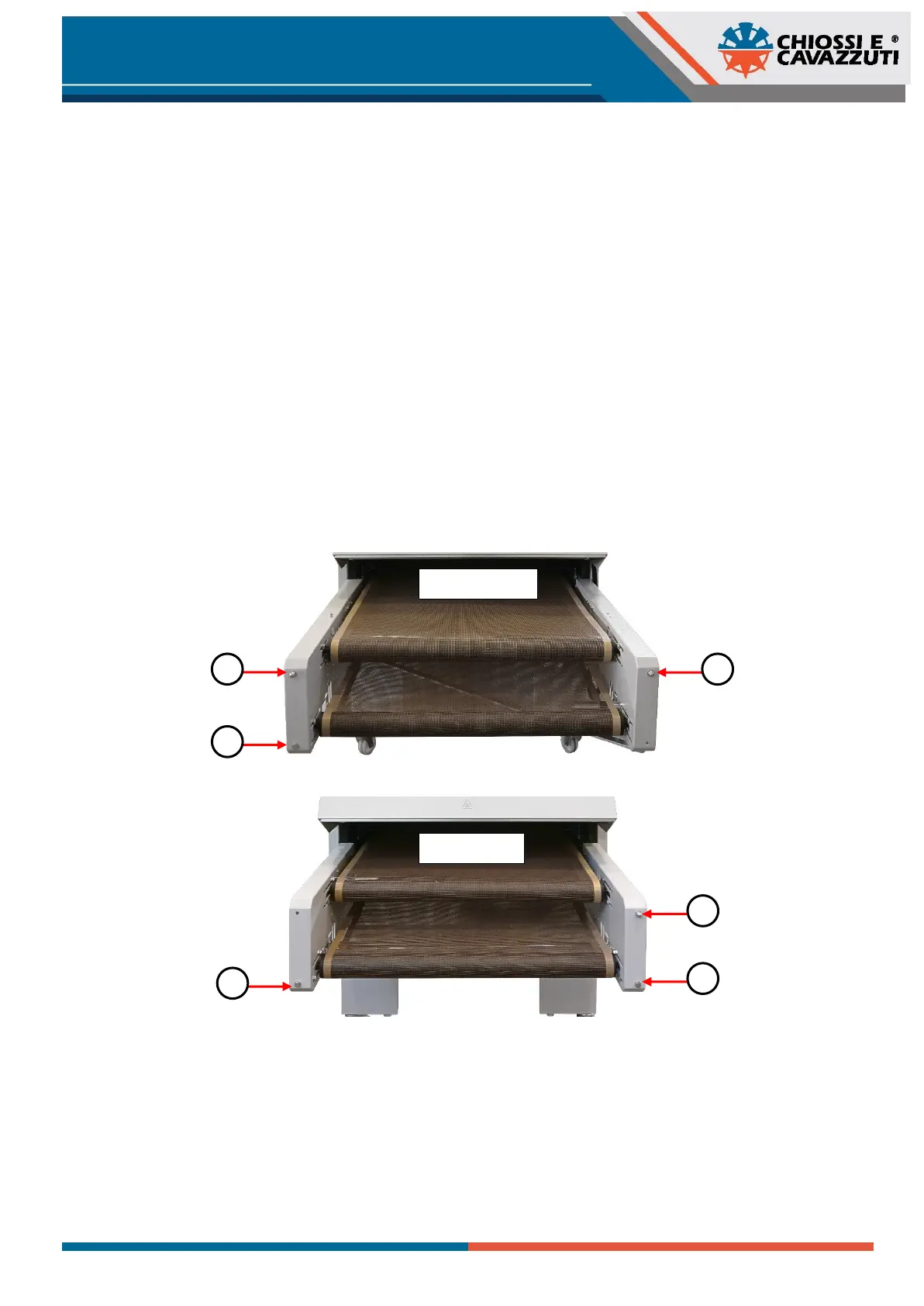

The motor of the upper belt is located in the outlet of the tunnel and has 2 registration screws in front (1a-2a) and only one

at the exit of the tunnel (3a).

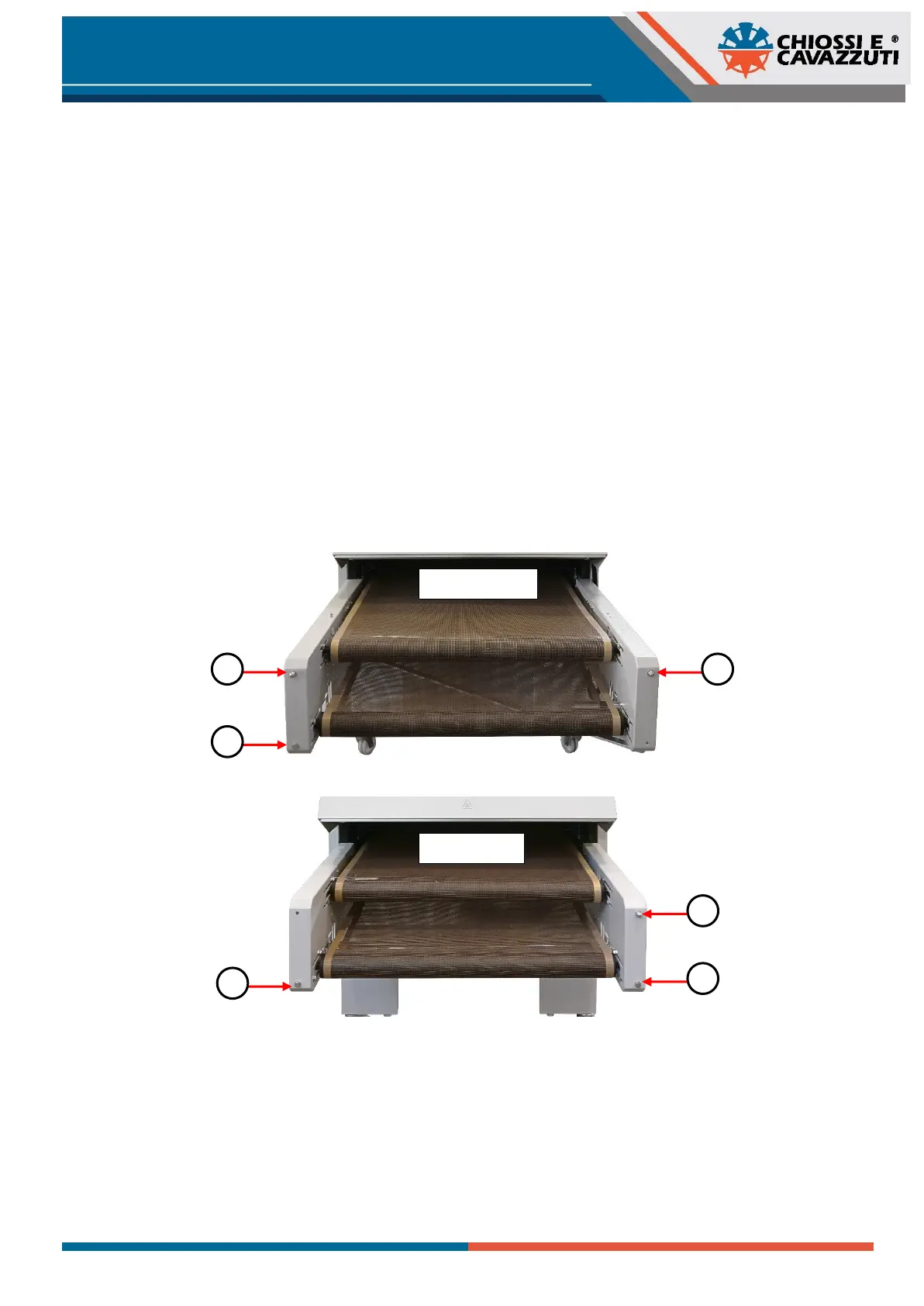

When available, the motor of the lower belt is located in the inlet of the tunnel and has only one registration screw in front

(3b) and two at the exit of the tunnel (1b-2b).

WARNING: Be careful to registrer the screw opposite to the motor. A disproportionate inclination of the roller results in an

overload on the motor bel. Screws 3a and 3b must be adjusted carefully!

Adjust with small steps on the screws (one rotation at a time) and observe carefully the behavior of the belt after each

adjustments.

Loading...

Loading...