0-5492 4-5 OPERATION

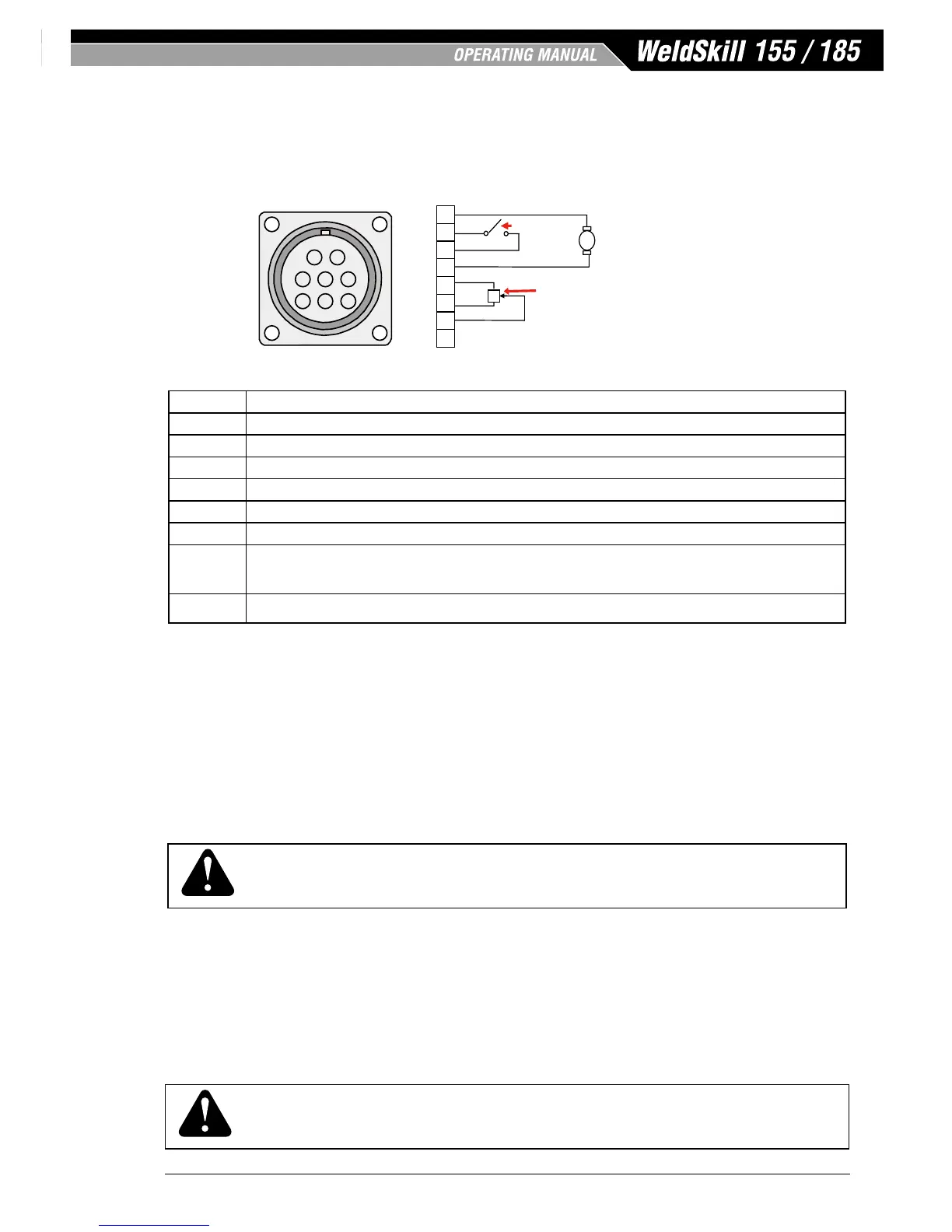

12. Remote Control Socket (WeldSkill 185 only)

The 8 pin Remote Control Socket is used to connect remote control devices (i.e. Spool Gun or Tig Torch) to

the welding power source. To make connections, align keyway, insert plug, and rotate threaded collar fully

clockwise.

Trigger Switch

Remote Wirespeed (Spool Gun) in GMAW mode

1

2

3

4

5

6

7

8

W

A-13456

3

4

5

6

7

8

1

2

Negative

Spool Gun Motor

Positive

Socket Pin

Function

1 Spool gun motor negative

2

Trigger Switch Input

3

Trigger Switch Input

4

Spool gun motor positive

5

5k ohm (maximum) connection to 5k ohm remote control potentiometer.

6

Zero ohm (minimum) connection to 5k ohm remote control potentiometer.

7

Wiper arm connection to 5k ohm remote control Wirespeed MIG (GMAW) mode potentiometer.

Wiper arm connection to 5k ohm remote control Amps TIG (GTAW) mode potentiometer.

8

Not connected

Table 4-1

Note that the remote/local switch (item 19) located in the wirefeed compartment should be set to remote for

the amperage/voltage controls to be operative.

13. Positive Welding Output Terminal

The positive welding terminal is used to connect the welding output of the power source to the appropriate

welding accessory such as the MIG torch (via the MIG torch polarity lead), electrode holder lead or work lead.

Positive welding current flows from the power source via this Dinse terminal. It is essential, however, that the

male plug is inserted and turned securely to achieve a sound electrical connection.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused in the Dinse terminal.

14. Negative Welding Output Terminal

The negative welding terminal is used to connect the welding output of the power source to the work lead. Most

General Purpose electrodes are connected with work lead to negative. Consult the electrode manufacturer’s

information for the correct polarity.

Welding current flows from the workpiece via this Dinse type terminal to the power source. It is essential,

however, that the male dinse type plug is inserted and turned securely to achieve a sound electrical connection.

Do not over tighten.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused in the Dinse terminal.

Loading...

Loading...