6-3

Manual No 0-5072

operation weldskill 250, 350

December 1, 2008

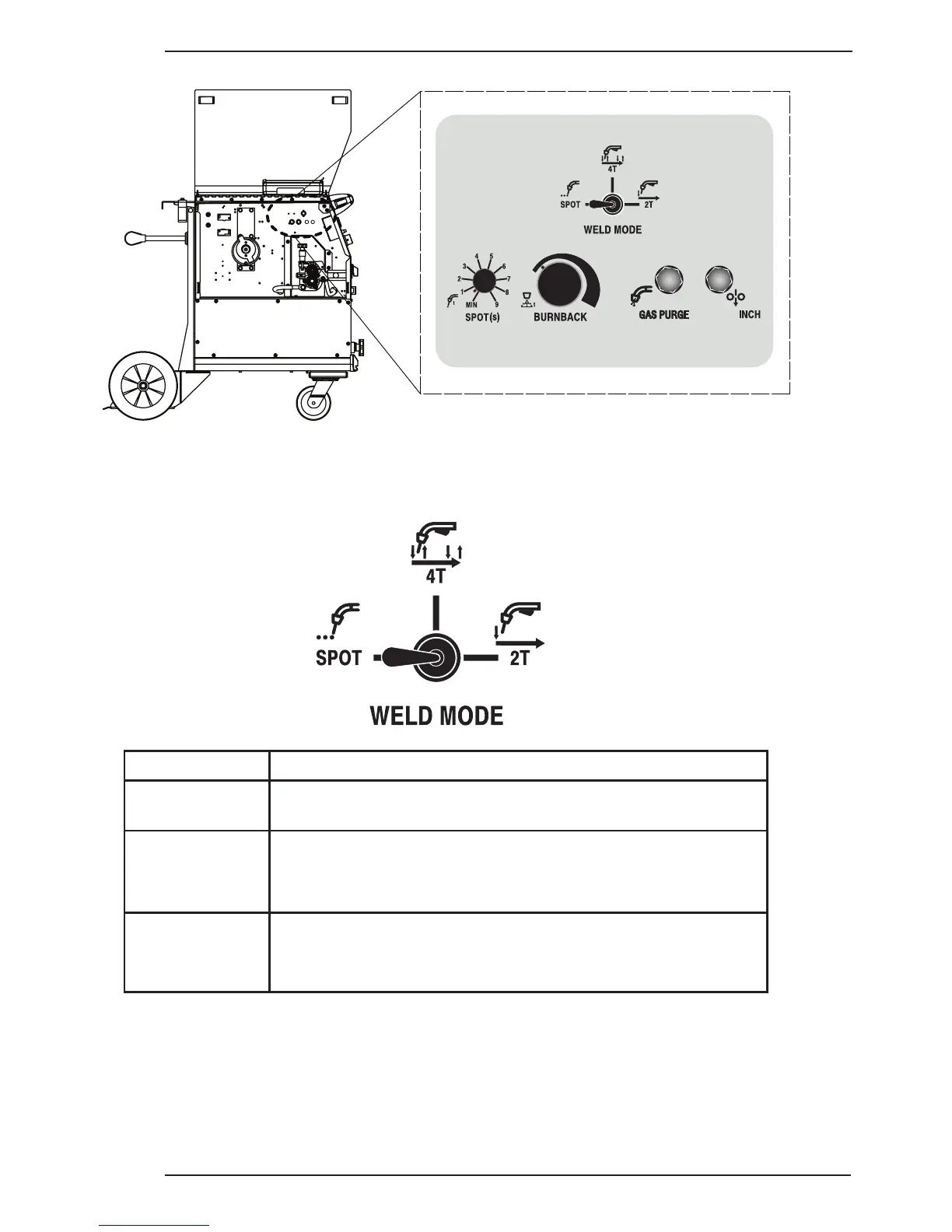

6.02 Internal Welding Controls

Figure 6-2 Internal welding controls

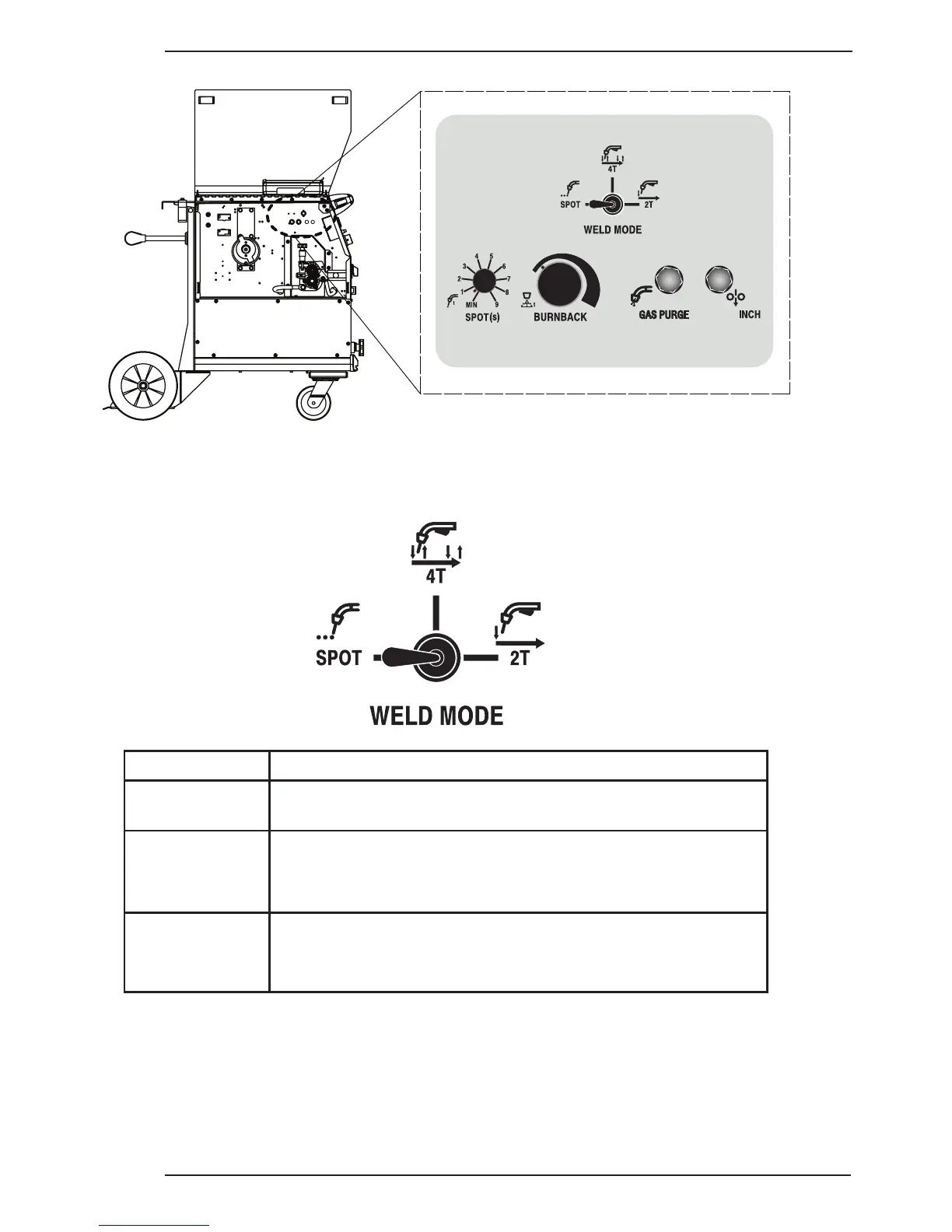

A. MODE SWITCH

The Weld Mode Selector switch selects the method of welding mode.

Mode Functional Description

CONTINUOUS (2T)

This mode of welding is used to weld two or more components together with

a continuous weld.

SPOT

This mode of welding is used to weld two plates together at a desired location

by melting the top & bottom plates together to form a nugget between them.

The spot time period is set by the SPOT TIME control shaft located in the

electrode wire compartment.

LATCH (4T)

This mode of welding is mainly used for long weld runs, as the operator need

only press the trigger to activate the weld, then press the trigger again to stop.

This obviates the need for the operator to depress the trigger for the complete

length of the weld run.

Table 6-1 Mode Switch Functional Description

Loading...

Loading...