78

Forks and Lift Chain

Lift Chain Inspection and Lubrication

During normal operation, inspect and lubricate the lift chains every 450 to 500 hours. If

operating in a corrosive or extreme working condition, inspect the lift chains more frequently.

Be sure to check for the following: corrosion, cracked plates, raised or turned pins, tight joints,

excessive wear, and worn pins and holes.

Lift chain lubrication is a critical part of your planned maintenance program. The correct and

timely lubrication of the lift chains will also maximize their service life.

Lift Chain Wear and Replacement Criteria

The lift chain will gradually stretch over time during normal operation. When a section of chain

has stretched 3% or more, it is considered excessively worn and must be replaced. When

checking for chain stretch, always measure a segment of chain that moves over a sheave.

WARNING

Do not attempt to repair a worn or broken lift chain.

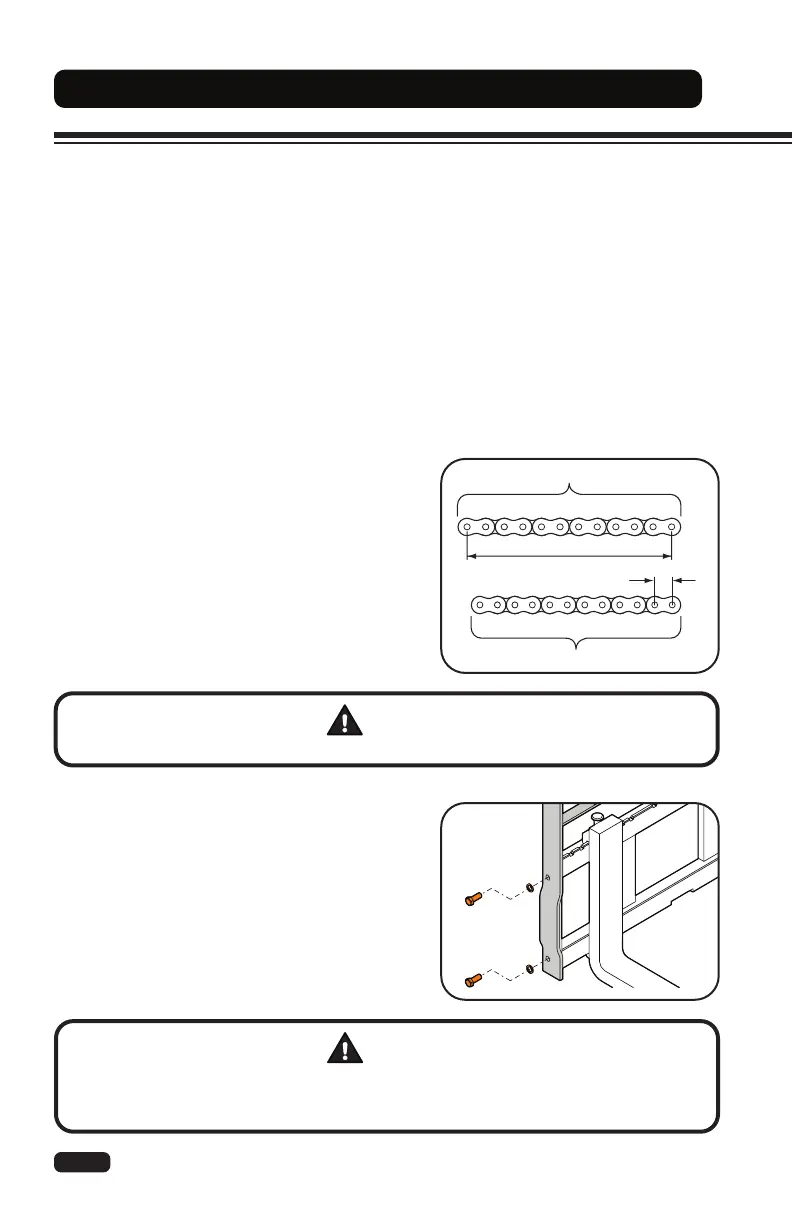

• New Chain Length (A): distance from the

rst pin counted to the last pin counted in a

span while the chains are lifting a small load.

• Worn Chain Length (B): distance from the

rst pin counted to the last pin counted in a

span while the chains are lifting a small load.

• Span (C): number of pins in the segment of

chain to be measured.

• Pitch (D): distance from the center of one pin

to the center of the next pin.

Load Backrest

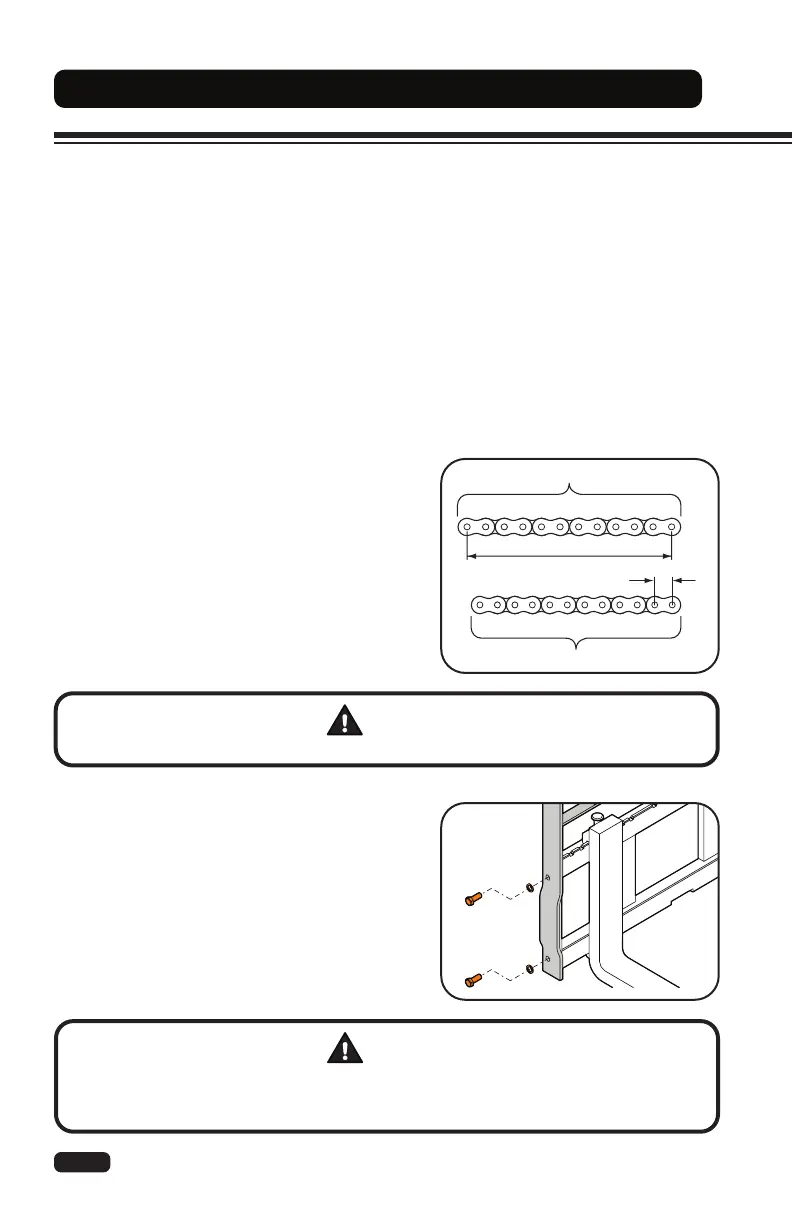

Check the condition of the load backrest. Inspect the

welds on the load backrest and carriage for cracks.

Check that the load backrest mounting fasteners are

not missing and properly tightened to specication. If

the load backrest has been removed, make sure that

fork stops have been installed on each side of the

carriage.

WARNING

If the lift truck is not equipped with a load backrest, or it has been removed, then fork

stops must be installed on each side of the carriage to prevent the forks from being

unintentionally forced o of the carriage during operation.

Loading...

Loading...