77

Section 6. Maintaining Your Lift Truck

Forks and Lift Chain

Forks and Lift Chain

Fork Inspection

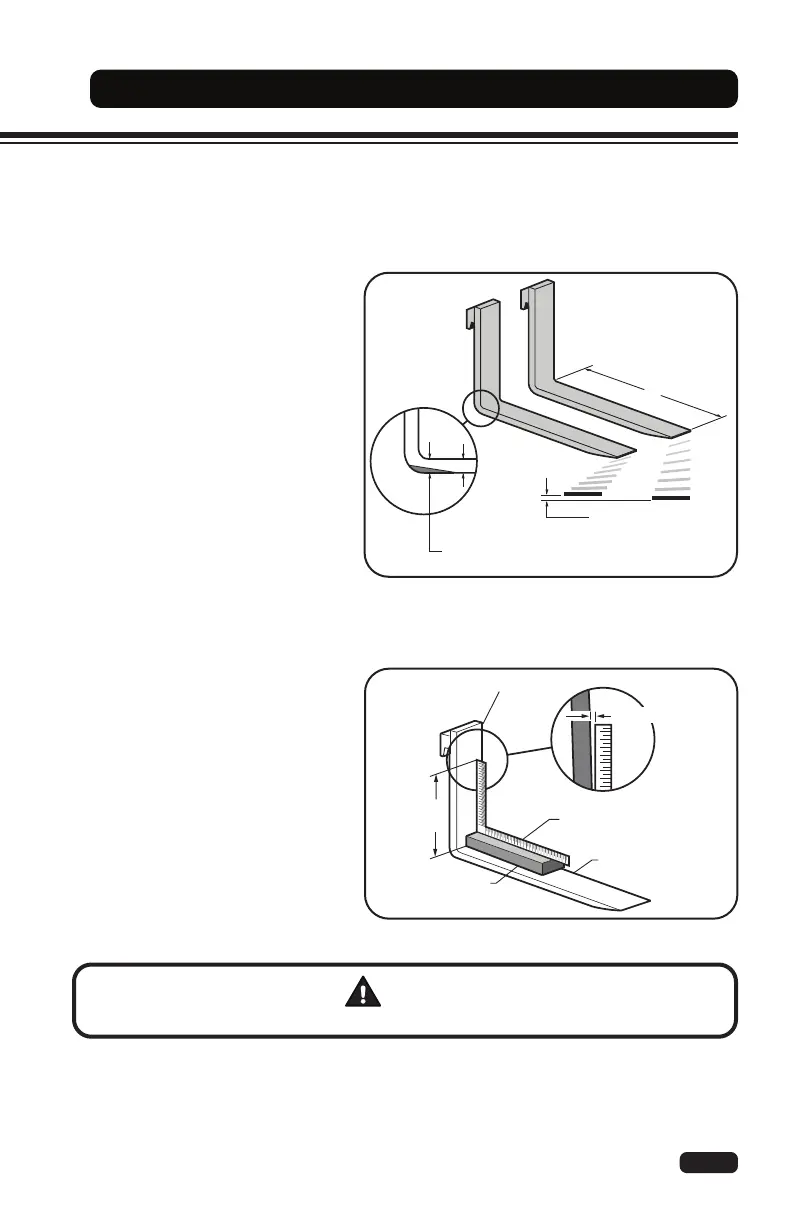

Inspect the load forks for bending and wear:

• The top surfaces of the forks should be level with each other.

• If the height dierence between the fork tips is greater than 1.5% of the blade length

(A), then the forks must be replaced.

• If the fork heel is worn by more

than 10% of the thickness (B)

of the fork blade, then the forks

must be replaced. The load

capacity of the forks is reduced

when the forks have experienced

excessive wear.

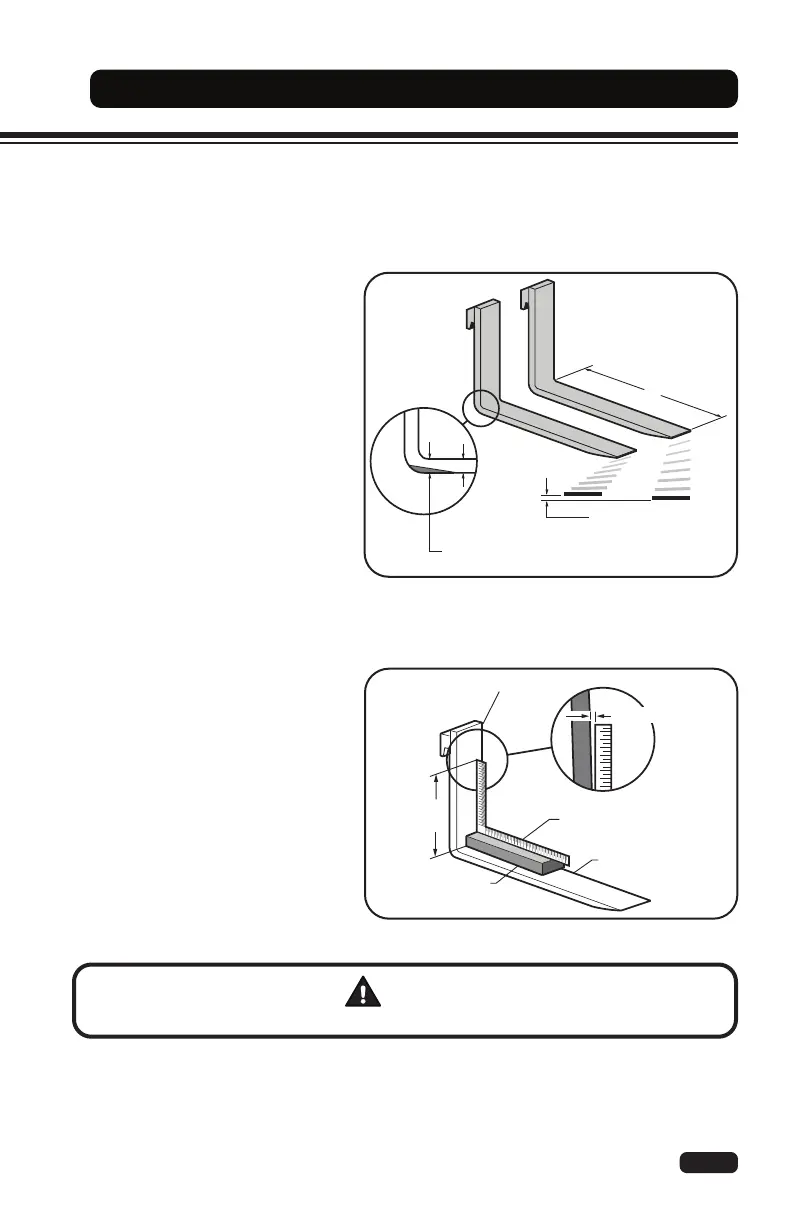

Inspect the forks for twists and bends:

• Position a 50 mm (2 in) thick block, at least 100 mm (4 in) wide and 600 mm (24 in)

long, on the blade of the fork with the 100 mm (4 in) surface against the blade.

• Position a 600 mm (24 in) square

on the top of the block and

against the shank.

• Check the fork gap at 500 mm

(20 in) above the blade. If the

gap distance is greater than 25

mm (1 in), then the forks must be

replaced.

WARNING

Do not operate a lift truck with bent, damaged, or worn forks.

Shank

Block

Square

Blade

1 in (25 mm) MAX

20 in

(500 mm)

A

B

10% of B is Maximum

Allowable Wear

1.5% of A is Maximum

Height Difference

Loading...

Loading...