16

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

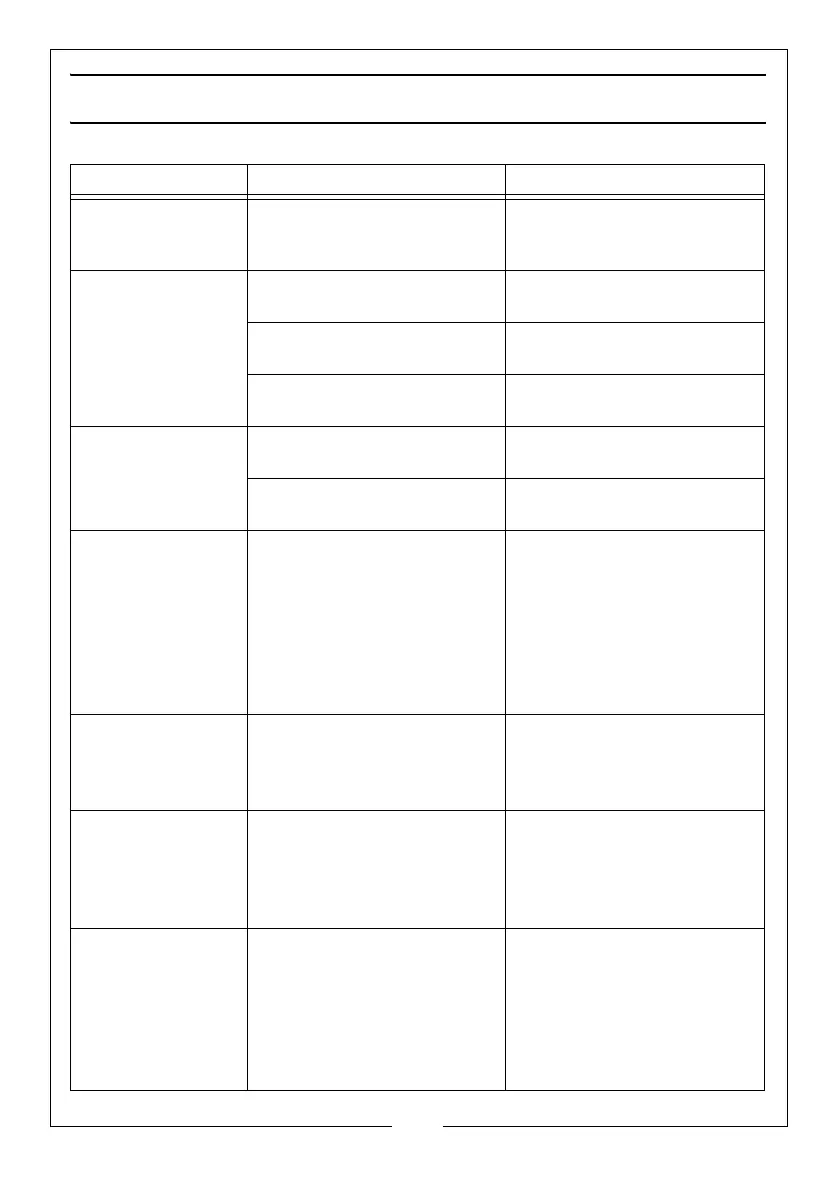

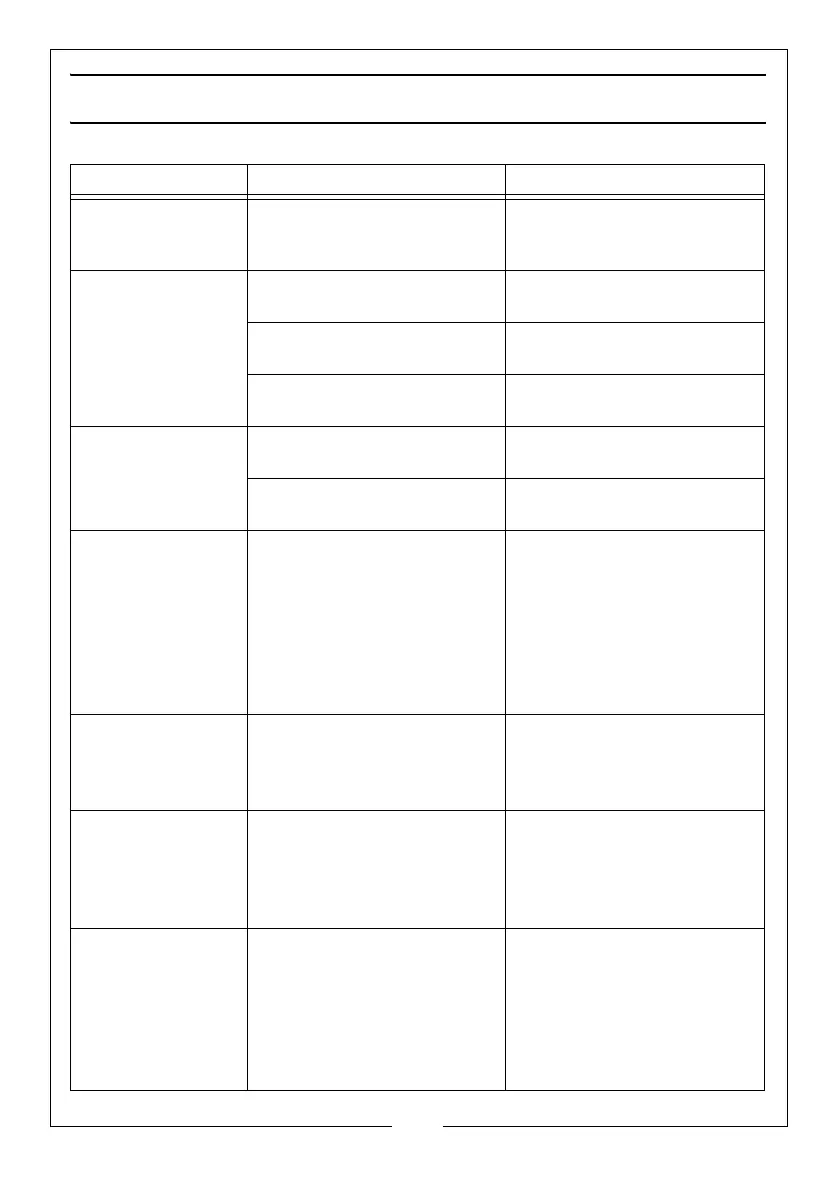

TROUBLESHOOTING

DEFECT CAUSES SUGGESTIONS

Unable to strike an

arc

Bad clamp connection.

Inverter printed circuit

board is defective.

Check clamp connection.

Contact your nearest

CLARKE dealer.

No output voltage Overheated machine (the

yellow LED should be on).

Wait for thermal cutout to

reset.

Internal relay has failed. Contact your nearest

CLARKE dealer.

Inverter printed circuit is

defective.

Contact your nearest

CLARKE dealer.

Wrong output

current

Current selector control is

defective.

Contact your nearest

CLARKE dealer.

Low power supply voltage. Check the mains distribution

system.

Porosity of welds Acid electrode on steel

with high sulphur content.

Electrode oscillates too

much.

Workpieces are too far

apart.

Workpiece being welded is

cold.

Use basic electrode.

Move edges to be welded

closer together. Move slowly

at the beginning.

Cracks in weld Material being welded is

dirty (e.g.oil, paint, rust,

oxides).

Not enough current.

Cleaning the workpiece

before welding is an

essential method of achiev-

ing neat weld beads.

Poor penetration Low current, high welding

rate, reversed polarity.

Electrode inclined in

position opposite to it's

movement.

Ensure operating variables

are correct and improve

preparation of work pieces.

Profile defects Welding parameters are

incorrect.

Pass rate is incorrect

operating parameter

requirements.

Electrode not inclined

constantly while welding.

Follow basic and general

welding principles.

Loading...

Loading...