9-4!

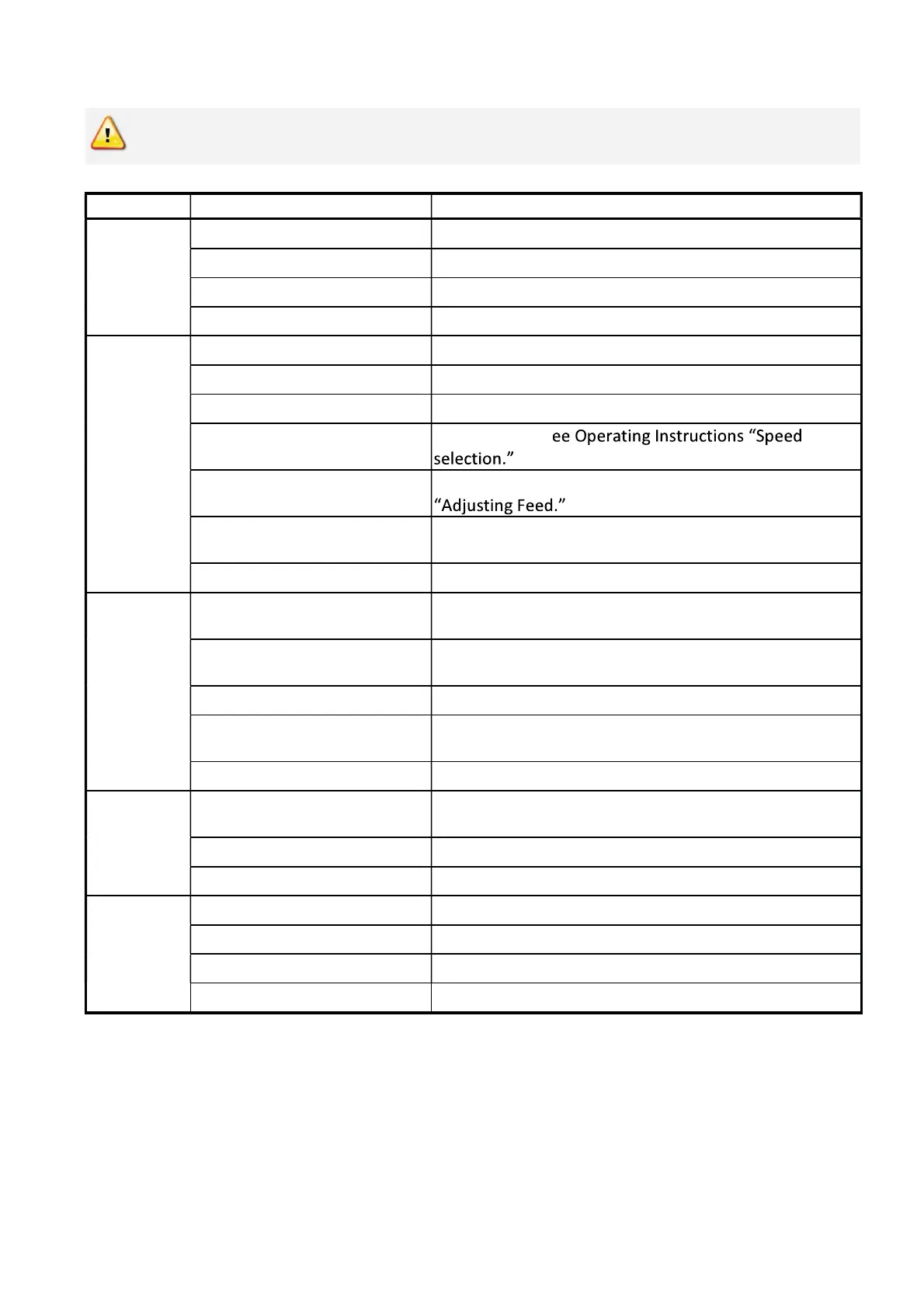

BLADE TROUBLES AND SOLUTIONS

DISCONNECT POWER CORD TO MOTOR BEFORE ATTEMPTING ANY REPAIR OR INSPECTION.

TROUBLE PROBABLE CAUSE SUGGESTED REMEDY

Teeth

strippage

Too few teeth per inch Use finer tooth blade

Loading of gullets Use coarse tooth blade or cutting lubricant.

Excessive feed Decrease feed

Work not secured in vise Clamp material securely

Blade

breakage

Teeth too coarse Use a finer tooth blade

Misalignment of guides Adjust saw guides

Dry cutting Use cutting lubricant

Excessive speed Lower speed. S

Excessive speed Reduce feed pressure. Refer to Operating Instructions

Excessive tension Tension blade to prevent slippage on drive wheel while

cutting.

Wheels out of line Adjust wheels

Blade line

Run-out or

Run-in

Guides out of line For a straight and true cut, realign guides, check

bearings for wear.

Excessive pressure Conservative pressure assures long blade life and clean

straight cuts.

Support of blade insufficient Move saw guides as close to work as possible.

Material not properly secured

in vise

Clamp material in vise, level and securely.

Blade tension improper Loosen or tighten tension on blade.

Blade

twisting

Blade not in line with guide

bearings

Check bearings for wear and alignment.

Excessive blade pressure Decrease pressure and blade tension

Blade binding in cut Decrease feed pressure

Premature

tooth wear

Dry cutting Use lubricant on all materials, except cast iron

Blade too coarse Use finer tooth blade

Not enough feed Increase feed so that blade does not ride in cut

Excessive speed Decrease speed

MS1318M / MS1318SA

Loading...

Loading...