9-5!

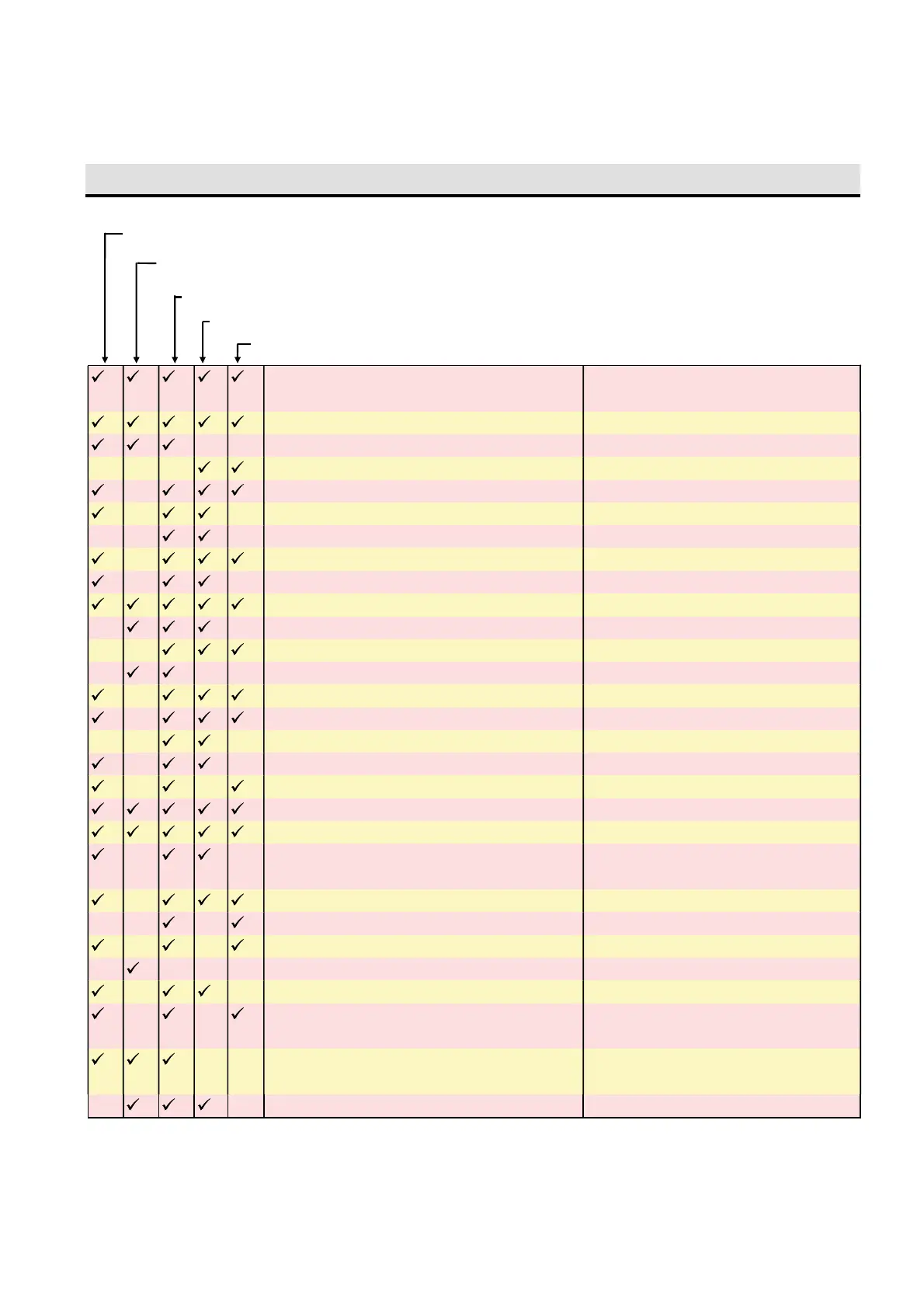

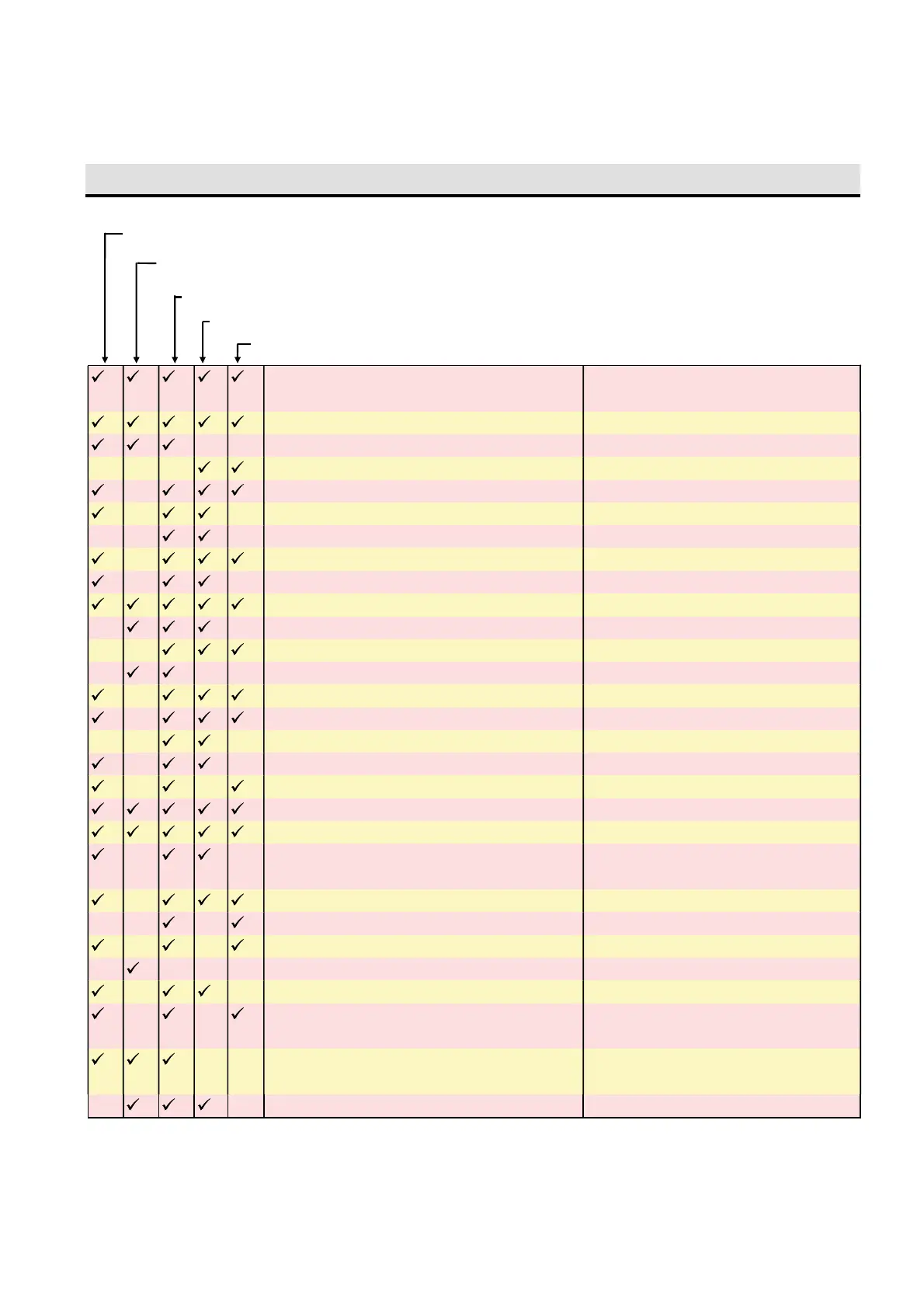

SAWING PROBLEMS AND SOLUTIONS

Other than this manual, the manufacturer also provides some related technical documents listed as

follows:

Sawing Problems and Solutions

Vibration during cutting

Failure to cut

Short life of saw blade

Curved cutting

Broken blade

Use of blade with incorrect pitch

Use blade with correct pitch suited

to workpiece width

Failure to break-in saw blade Perform break-in operation

Excessive saw blade speed Reduce speed

Insufficient saw blade speed Increase speed

Excessive saw head descending speed Reduce speed

Insufficient saw head descending speed Increase speed

Insufficient saw blade tension Increase tension

Wire brush improperly positioned Relocate

Blade improperly clamped by insert Check and correct

Improperly clamped workpiece Check and correct

Excessively hard material surface Soften material surface

Excessive cutting rate Reduce cutting rate

Non-annealed workpiece Replace with suitable workpiece

Insufficient or lean cutting fluid Add fluid or replace

Vibration near machine Relocate machine

Non-water soluble cutting fluid used Replace

Air in cylinder Bleed air

Broken back-up roller Replace

Use of non-specified saw blade Replace

Fluctuation of line voltage Stabilize

Adjustable blade guide too far from

workpiece

Bring blade guide close to

workpiece

Loose blade guide Tighten

Blue or purple saw chips Reduce cutting rate

Accumulation of chips at inserts Clean

Reverse positioning of blade on machine

Reinstall

Workpieces are not bundled properly Re-bundle

Back edge of blade touching wheel

flange

Adjust wheel to obtain clearance

Workpiece of insufficient diameter Use other machine, suited for

diameter of workpiece Replace

Saw blade teeth worn Replace

MS1318M / MS1318SA

Loading...

Loading...