750-368

CBEX Elite 100-1200 HP

1-5

1.4 — Steam Controls (all fuels)

1. Low Water Cutoff and Pump Control: Float-operated control responds to the water level in the boiler. It per-

forms two distinct functions:

•Stops firing of the burner if water level lowers below the safe operating point. Energizes the low-water light in

the control panel; also causes low-water alarm bell (optional equipment) to ring. Code requirements of some

models require a manual reset type of low water cutoff.

•Starts and stops the feedwater pump (if used) to maintain water at the proper operating level.

2. Water Gauge Glass Drain Valve: Provided to flush the gauge glass.

3. Vent Valve: Allows the boiler to be vented during filling and facilitates routine boiler inspection as required by

ASME Code.

4. Water Column Drain Valve: Provided so that the LWCO and its piping can be flushed regularly to assist in

maintaining cross-connecting piping and in keeping the float bowl clean and free of sediment. A similar drain

valve is furnished with auxiliary low water cutoff for the same purpose.

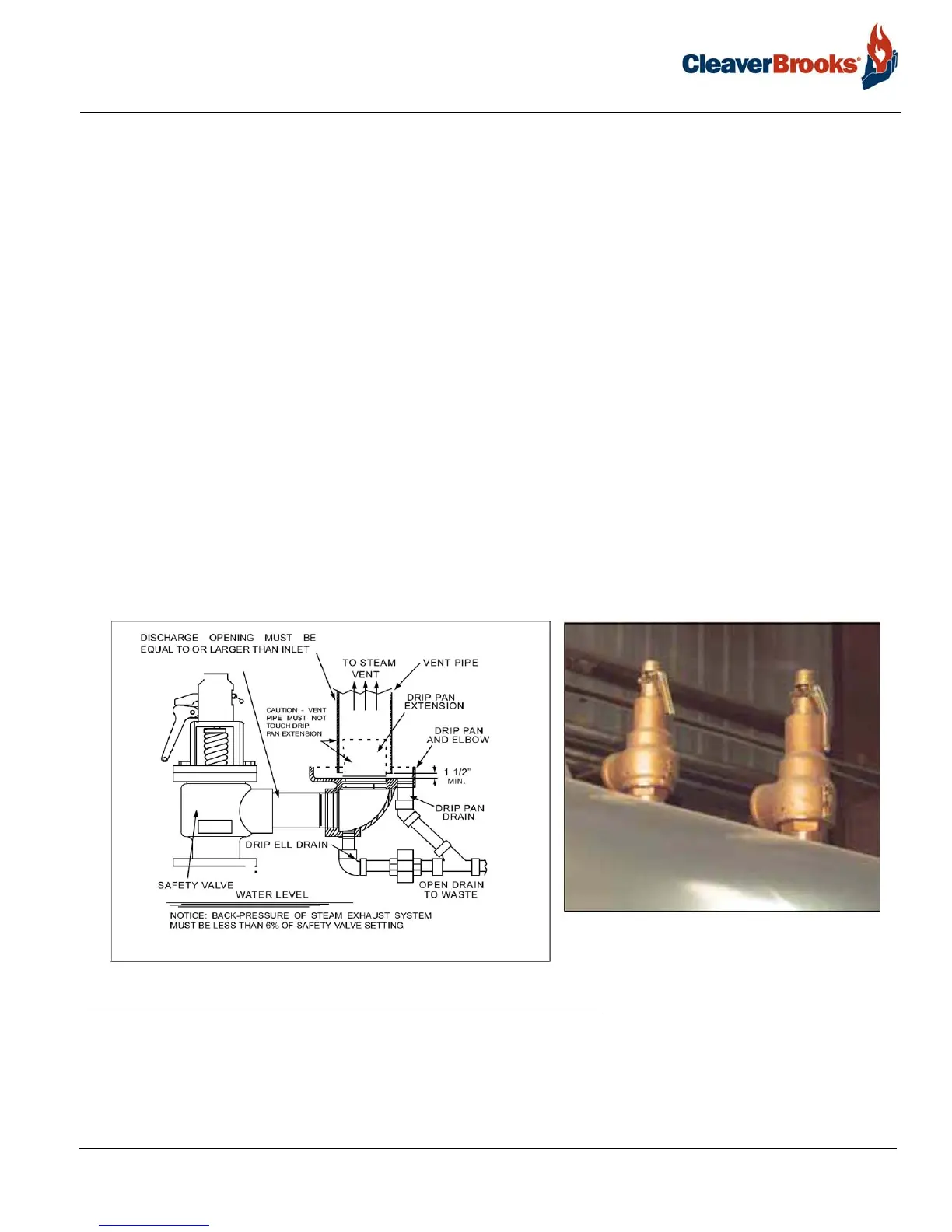

1.4.3 — Safety Valve(s)

Safety Valves: Prevent buildup over the design pressure of the pressure vessel. The size, rating, and number of

valves on a boiler is determined by the ASME Boiler Code. The safety valves and the discharge piping are to be

installed to conform to the ASME Code requirements. The installation of a valve is of primary importance to its

service life. A valve must be mounted in a vertical position so that discharge piping and code-required drains can

be properly piped to prevent buildup of back pressure and accumulation of foreign material around the valve seat

area. Apply a moderate amount of pipe compound to male threads and avoid over-tightening, which can distort

the seats. Use only flat-jawed wrenches on the flats provided. When installing a flange connected valve, use a

new gasket and draw the mounting bolts down evenly. Do not install or remove side outlet valves by using a pipe

or wrench in the outlet.

FIGURE 1-4. Safety Valve Piping and Safety Valves

Loading...

Loading...