Inspection and Maintenance

8-14

750-368

CBEX Elite 100-1200 HP

Lubricate occasionally with a non-gumming, dripless, high-temperature lubricant such as graphite or a silicone

derivative.

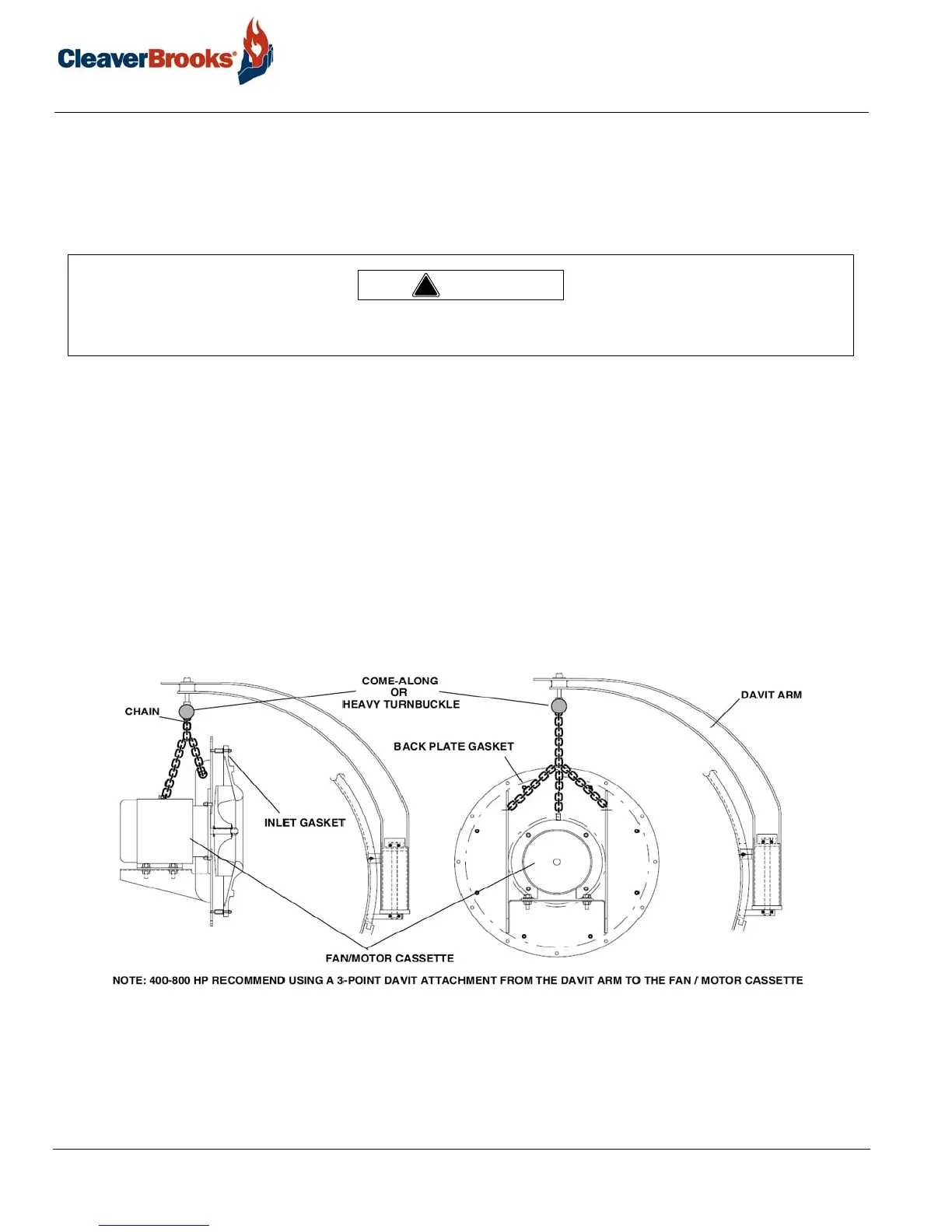

8.12 — Fan/Motor Cassette Removal

Before the boiler is commissioned at the job site, the Integral Flue Gas Recirculating (IFGR) system should be

visually inspected. The fan/motor cassette should be removed to expose the internal IFGR linkage and damper.

Remove the fan/motor cassette as follows:

1. Disconnect and lockout electric power to the boiler.

2. Be sure that the front door is securely bolted to the boiler.

3. Release the davit arm by removing the retaining bolt at the top center of the boiler.

4. Connect the davit arm to the fan/motor cassette using the suspension system shown in Figure 8-11.

5. Arrange the attaching chains so the lifting point is over the motor shaft centerline and the center of balance

for the fan/motor cassette. This point is approximately 4 inches from the motor backplate for 600-800 HP

units, and 3 inches for 250-500 units.

6. Remove the fan/motor cassette fastening nuts.

7. Swing the fan/motor cassette to the side and secure it to the boiler using high strength cord. Do not over-

extend the motor wires.

BEFORE removing the fan/motor cassette, disconnect and lockout electrical power to the boiler and ensure the front

door is securely bolted to the boiler. Failure to follow these instructions could result in serious injury or death.

Loading...

Loading...