Inspection and Maintenance

8-24

750-368

CBEX Elite 100-1200 HP

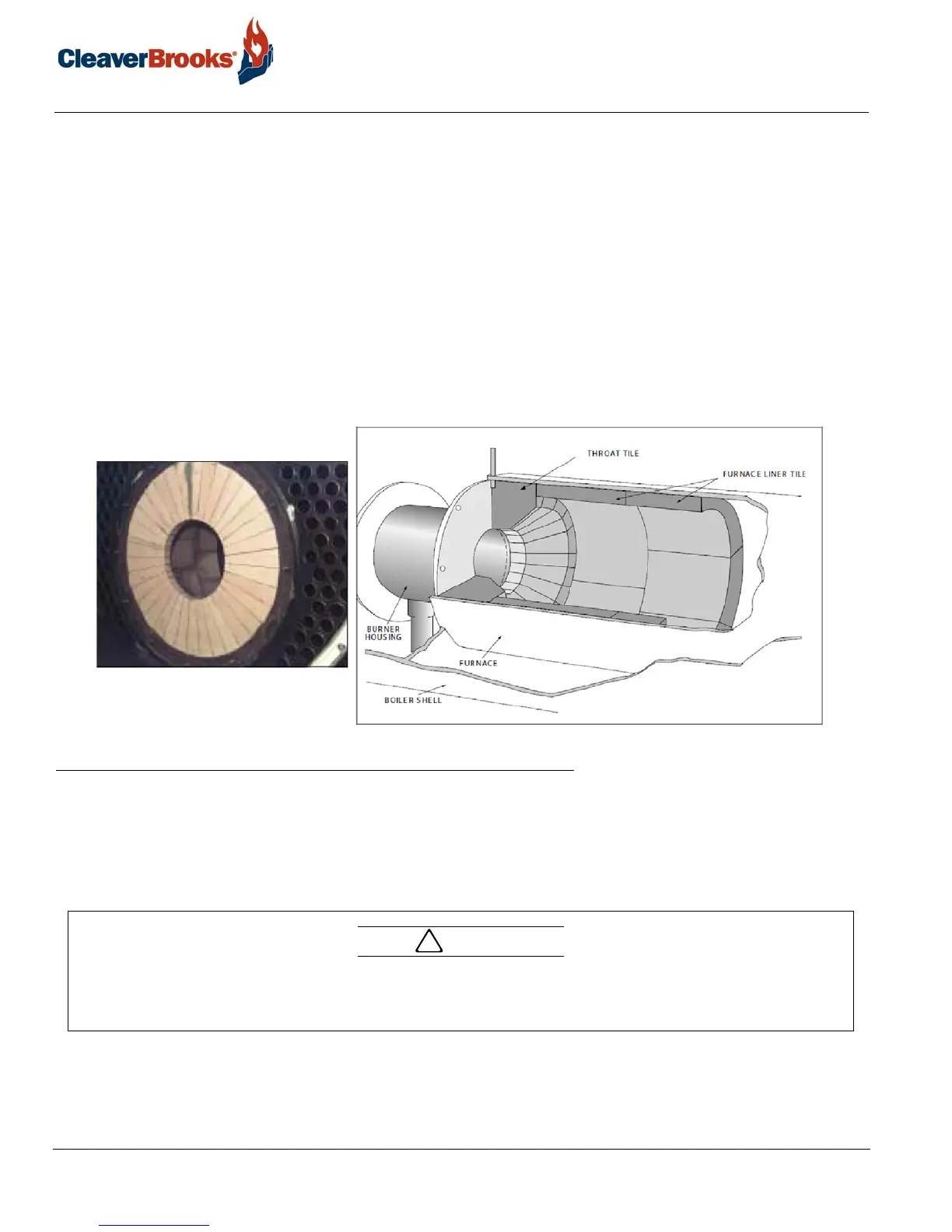

8.18 — Refractory

The boiler is shipped with completely installed refractory. This consists of furnace throat tile, furnace liner, and

the crawl-way plug. Normal maintenance requires little time and expense, and prolongs the operating life of the

refractory.

Preventive maintenance through periodic inspection will keep the operator informed of the condition of the

refractory, and will guard against unexpected and unwanted downtime and major repairs.

Frequent wash coating of the refractory surfaces is recommended. High-temperature bonding, air-dry type mor-

tar, diluted with water to the consistency of light cream, is used for wash coating. Re-coating intervals will vary

with operating loads and are best determined by the operator when the boiler is opened for inspection.

FIGURE 8-20. Throat Tile and Furnace Liner

8.18.1 — Furnace Liner

Maintenance consists of occasional wash coating of the entire liner. Face all joints or cracks by applying high

temperature bonding mortar with a trowel or fingertips. Wash coating should be done as soon as cracks are

detected.

Should segments of the liner burn away or fall out, replace the entire refractory piece. Any refractory that may

break out should be removed as soon as detected so that it will not fuse to the bottom of the furnace and

obstruct the flame.

The area between the burner housing and the throat tile requires a good seal. An improper or poor seal allows air

leaks that can cause overheating and burning of the burner housing metal. The area should be inspected semi-annu-

ally. Contact your local Cleaver-Brooks representative.

Loading...

Loading...