Burner and Fuel System

2-4

750-368

CBEX Elite 100-1200 HP

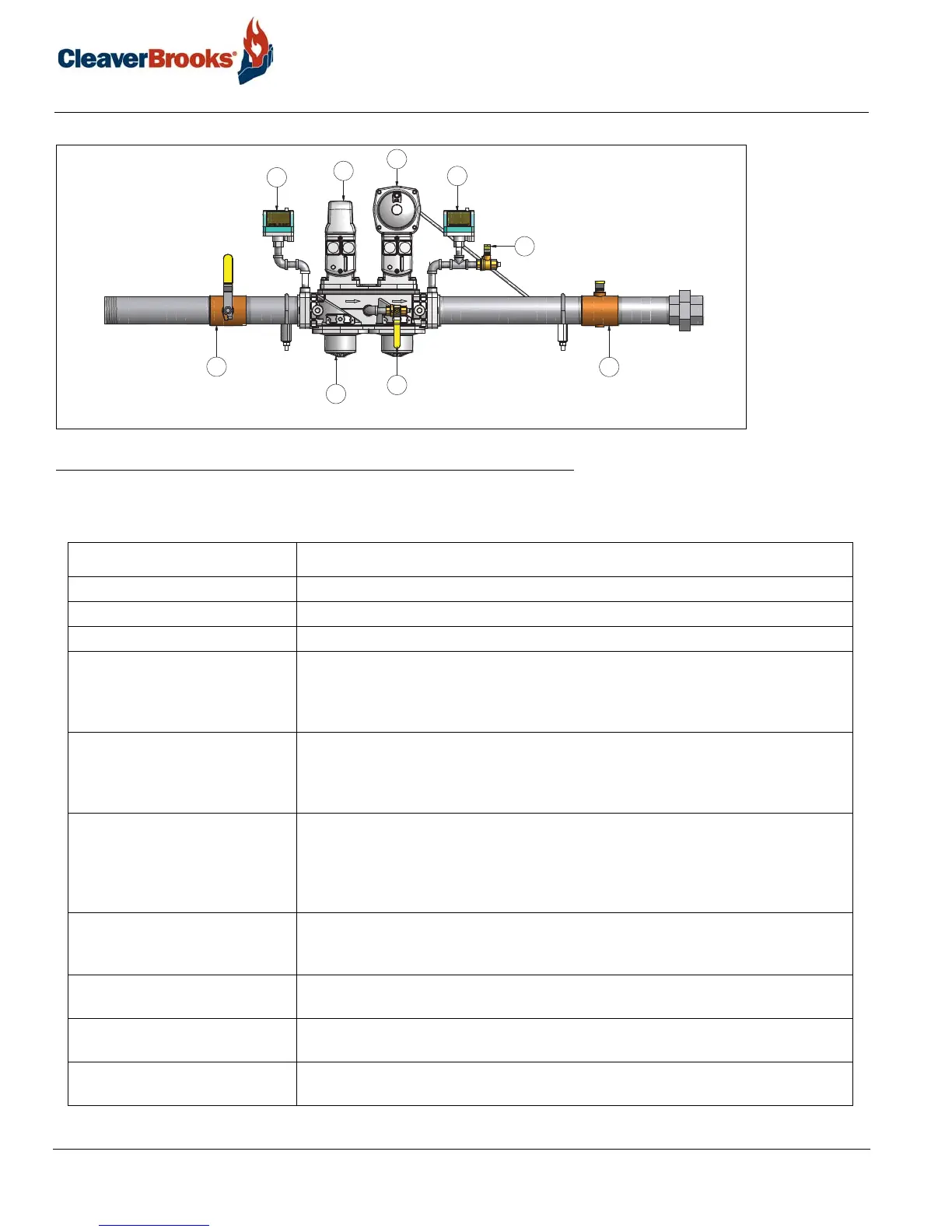

FIGURE 2-3. Main Gas Train

Component Description

1. Pilot Gas Shutoff Cock For manually opening or closing the pilot gas supply.

2. Pilot Gas Pressure Regulator Reduces incoming gas pressure to suit the pilot.

3. Pilot Gas Pressure Gauge Indicates gas pressure to pilot.

4. Pilot Gas Valve A solenoid valve that opens during the ignition period to admit fuel to the pilot. It

closes after main flame is established. The sequence of energizing and de-energiz-

ing is controlled by the programming relay. A second gas pilot valve may be

required by insurance regulations.

5. Gas Shutoff Cock The upstream gas cock manually opens and closes the main fuel gas supply. A

second shutoff cock, downstream of the main gas valve(s), is installed to provide

a means of shutting off the gas line whenever a test is made for leakage across the

main gas valve.

6. Low Gas Pressure Switch A pressure actuated switch that is closed whenever main gas line pressure is

above a preselected pressure. Should the pressure drop below the setting, the

switch contacts open a circuit causing the main gas valve(s) to close, or prevent

the burner from starting. The switch is usually equipped with a device that must

be manually reset after being tripped.

7. Main Gas Valves Electrically actuated shutoff valves that open simultaneously to admit gas to the

burner. The downstream valve is equipped with a “proof of closure” switch that is

connected into the pre-ignition interlock circuit.

8. Gas Valve Actuator w/o POC Dual-body gas valve includes regulating valve with POC (see below) and second

motorized safety shutoff valve.

9. Leakage Connection The body of the gas valve has a plugged opening that is used whenever it is nec-

essary to conduct a test for possible leakage across the closed valve.

10. Gas Regulating Actuator w/

POC

Regulates gas pressure to the pressure range required by the burner. Includes

proof-of-closure switch.

Loading...

Loading...