Waterside Care

3-4

750-368

CBEX Elite 100-1200 HP

Pump Operation

Pumps are normally started and stopped by manual switches. It is also desirable to interlock the pump with the

burner so that the burner cannot operate unless the circulating pump is running.

Pressure

The design of the system and usage requirements often dictate the pressure exerted upon the boiler. Some sys-

tems are pressurized with air, or with an inert gas such as nitrogen. Caution must be exercised to ensure that the

proper relationship of pressure-to-temperature exists within the boiler so that all of the boiler’s internal surfaces

are fully wetted at all times. For this reason, the internal boiler pressure, as indicated on the water pressure

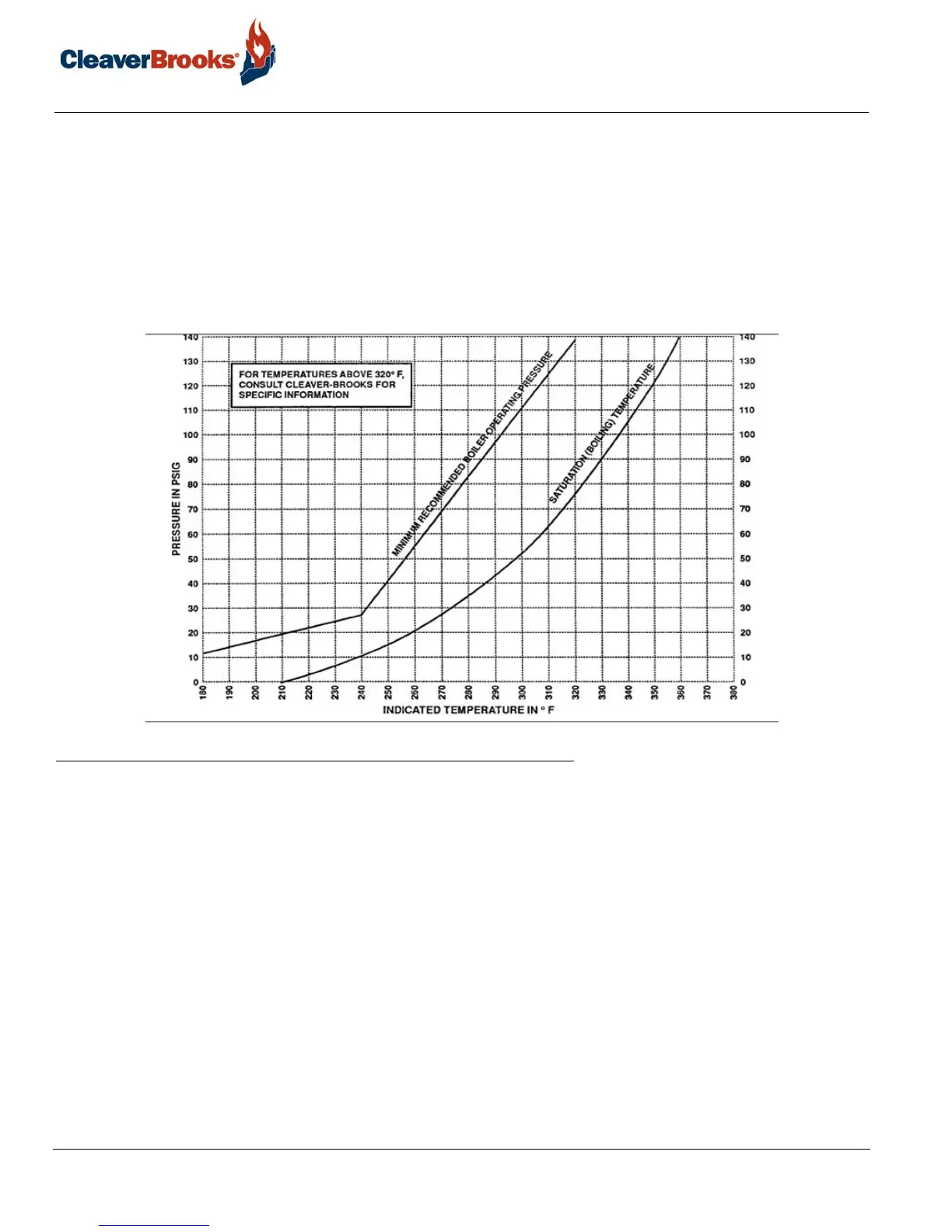

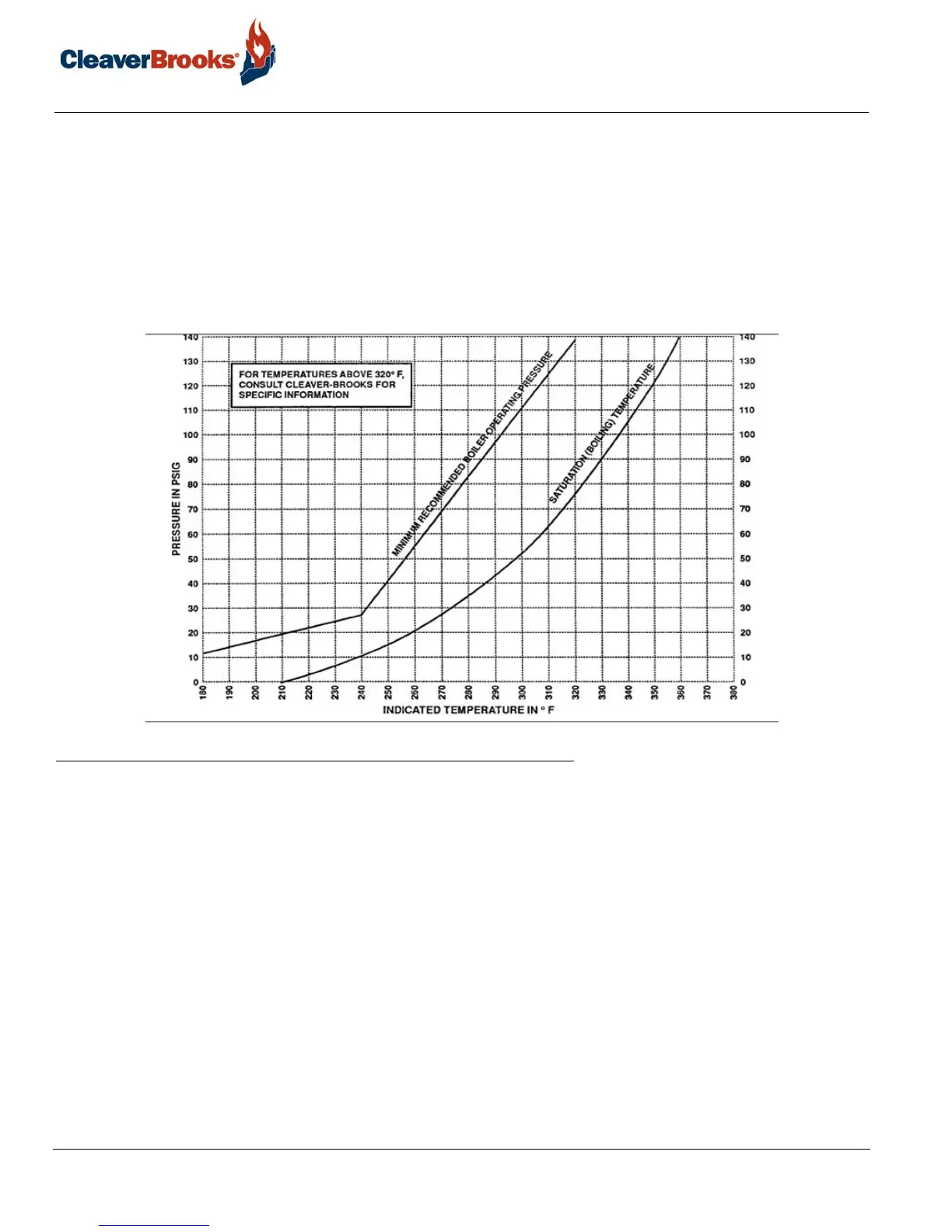

gauge, must be held to the level shown in the Internal Boiler Pressure graph below.

FIGURE 3-3. Internal Boiler Pressure

When initially firing a newly installed boiler, or when cutting an existing boiler into an operating system, the

boiler or boilers to be cut into operation MUST be pressurized equal to the system and/or other boilers prior to

opening the header valves.

It is advisable to have a thermometer installed in the return line to indicate return water temperature. Knowing

the supply water temperature, the boiler system differential can be established. With knowledge of the pumping

rate, the operator can easily detect any excessive load condition and take appropriate corrective action.

Special caution must be taken to guard against any condition, or combination of conditions, that might lead to

the transfer of cold water to a hot boiler or hot water to a cold boiler. It cannot be over-emphasized that rapid

changes in temperature within the boiler can, and sometimes do, cause damage.

3.2.2 — Steam Boilers

Feed Pump Operation

Loading...

Loading...