CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility

®

Compact Belt Drive (TCH/V) Series

Rev.: July 25, 2017

18

ClimateMaster Water-Source Heat Pumps

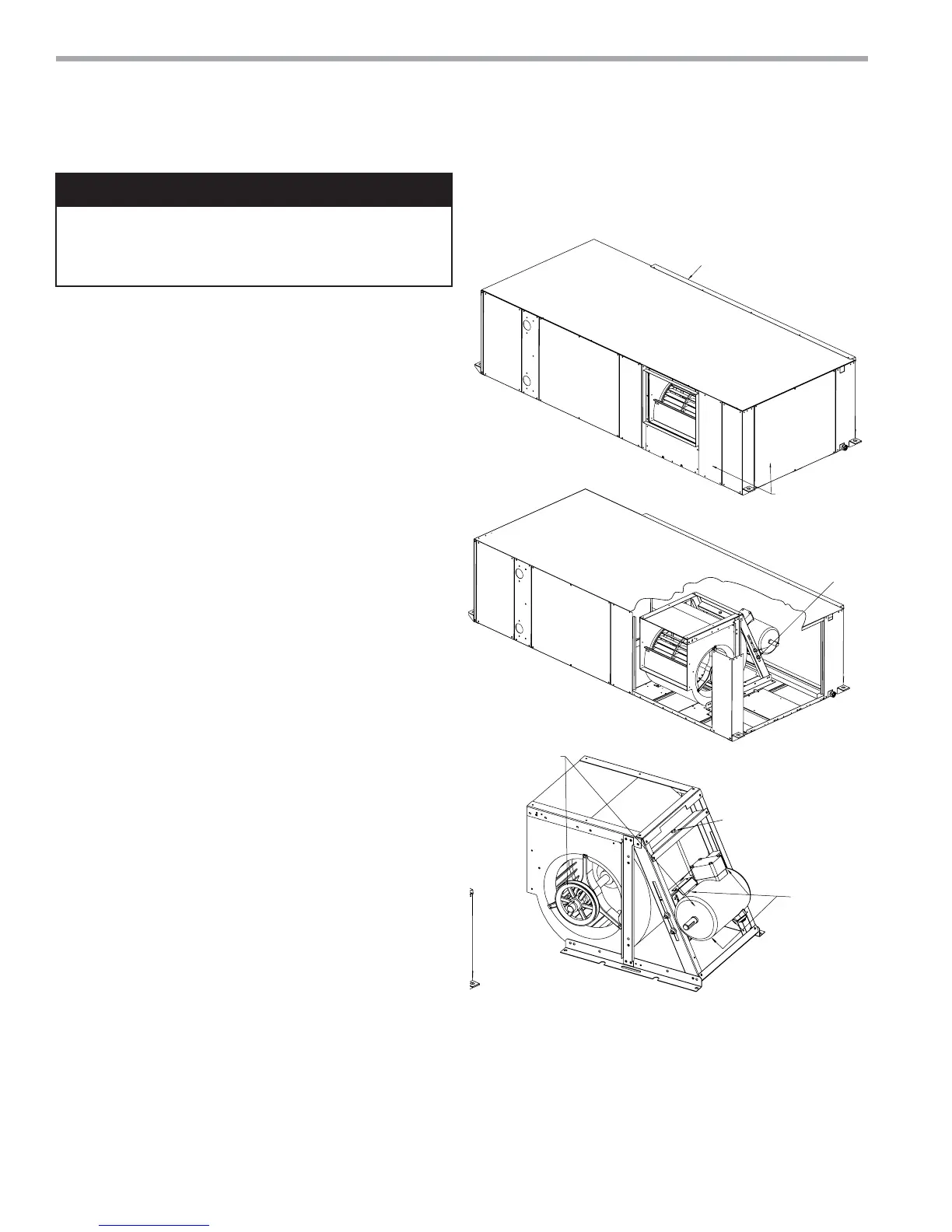

TCH Field Conversion of Air Discharge

Overview -

Horizontal units can be fi eld converted

between straight (side) and back (end) discharge using

the instructions below.

Note: It is not possible to fi eld convert return air

between left or right return models due to the

necessity of refrigeration copper piping changes.

Preparation - Field conversion must be completed on

the ground. If the unit is already hung it should be taken

down for the fi eld conversion. Place in a well-lighted

area. Conversion should only be attempted by a qualifi ed

service technician.

Side to Back Discharge Conversion

1. Remove back panel and side access panel

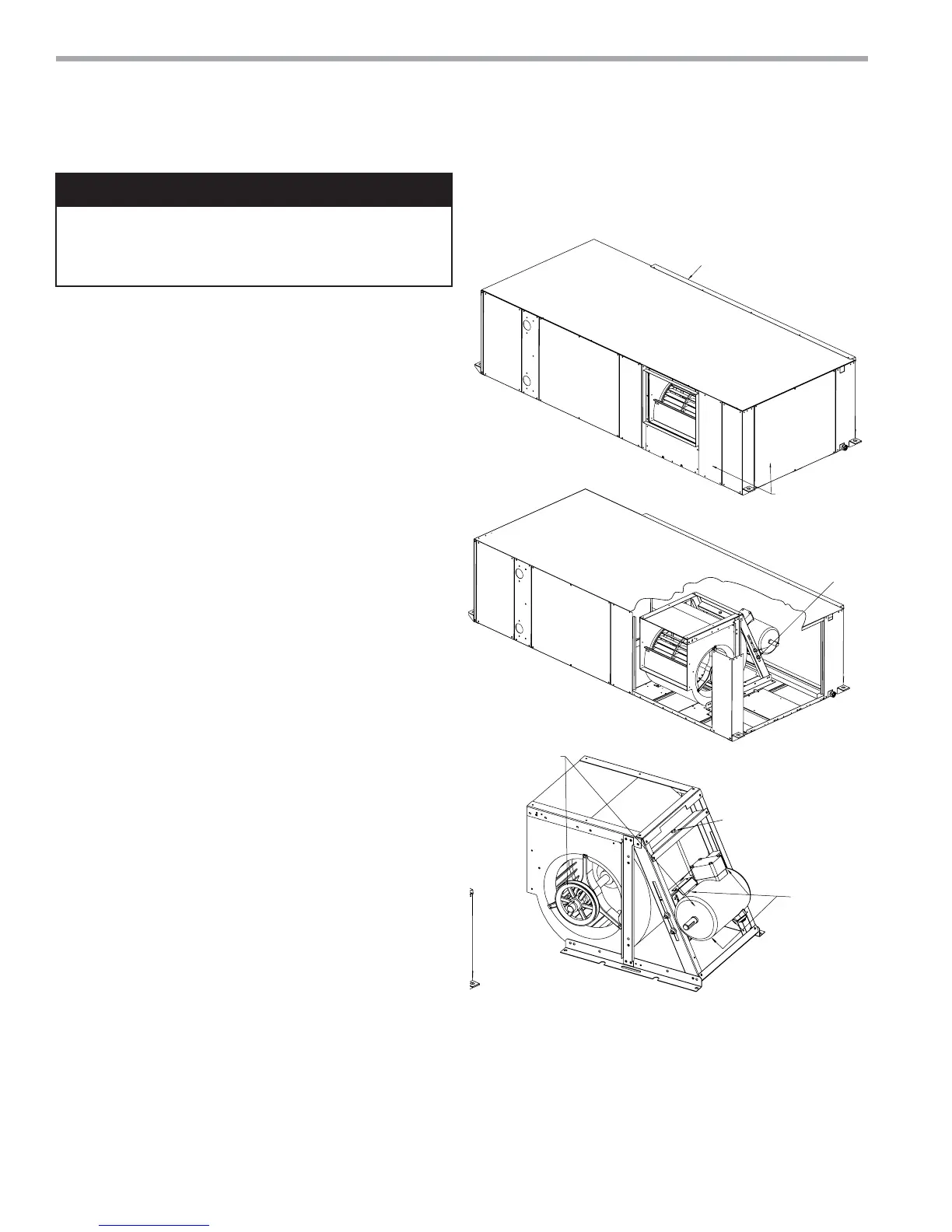

2. Loosen 2 motor slide nuts, raise motor slide assembly

and remove belt and motor sheave.

3. Remove blower sheave. Remove motor bolts and

carefully remove motor.

4. Remove 2 motor clips and reattach to opposite side.

5. Unbolt (3 per side) complete housing assembly.

6. Rotate complete assembly into new position. Locate

over mounting holes in base, reattach using 3 bolts per

side.

7. Mount motor, motor sheave, blower sheave and belt.

Make sure wires are not pinched and not over sharp

edges. Adjust motor downward to tighten belt. Raise

or lower motor slide assembly with adjusting bolt

and retighten 2 slide nuts. Check for correct tension

(See Tensioning V-Belt Drives page). Rewire motor (at

contactor) for correct rotation. Spin blower wheel to

ensure wheel is not obstructed.

8. Replace 2 panels.

Back to Side Discharge Conversion - If the discharge is

changed from back to side, use above instruction noting

that illustrations will be reversed.

Left vs. Right Return - It is not possible to fi eld convert

return air between left or right return models due to the

necessity of refrigeration copper piping changes. However,

the conversion process of side to back or back to side

discharge for either right or left return confi guration is

the same. In some cases, it may be possible to rotate the

entire unit 180 degrees if the return air connection needs

to be on the opposite side. Note that rotating the unit will

move the piping to the other end of the unit.

WARNING!

Step 2

Loosen 2 motor slide nuts,

raise slide assembly, remove

Step 1

R

a

Remove blower panel

and access panel

Return air

Front

Figure 4: Left Return Side Discharge to Back

Figure 4 Continued on Following Page

Step 3

Remove motor

and blower

Adjusting bolt -

used to raise or

lower motor slide

Remove 4

motor bolts

WARNING! To avoid possible injury or death due to

electrical shock, open the power supply disconnect switch

and secure it in an open position during installation or

conversion.

Loading...

Loading...