43

9 - MAINTENANCE

9.2 Generality

Maintenance must be carried out authorised after-sales

assistance centres or by specialised personnel.

Maintenance allows:

maintaining the unit efficient

reduce deterioration speed to which each equipment

is subject in time

collect information and data to understand the

efficiency state of the unit and prevent possible faults

Frequency of the inspections must be at least six-monthly

However, frequency depends on the type of use.

heavy (continuous or highly intermittent, near to

operation limits, etc.)

critical (essential service).

9.3 Frequency of interventions

9.4 Machine schedule

Foresee a machine schedule to keep trace of the

interventions made on the unit.

In this way, it will be easier to adequately schedule the various

interventions and facilitate any troubleshooting.

On the schedule note:

date

type of intervention made

description of intervention

measurements taken, etc. .

If foreseen a long period of inactivity:

disconnect voltage to avoid electric risks or damages

following lightning

prevent the risk of freezing (empty or glycol the

sections of the system exposed to negative

temperatures, keep any antifreeze heaters powered)

It is advised that start-up after a period of inactivity be carried

out by a qualified technician, in particular after seasonal stops

or for seasonal switch-over.

Upon start-up, follow that indicated in the START-UP section.

Plan in advance the technician intervention to prevent

misunderstandings and be able to use the system when

required

9.5 Stand-by

9.6 Structure

Check the state of the parts constituting the structure.

Treat those parts of the unit subject to oxidation, with paints

act at eliminating or reducing the oxidation phenomena.

Check fastening of the unit external panelling.

Bad fastening give rise to anomalous noises and vibrations.

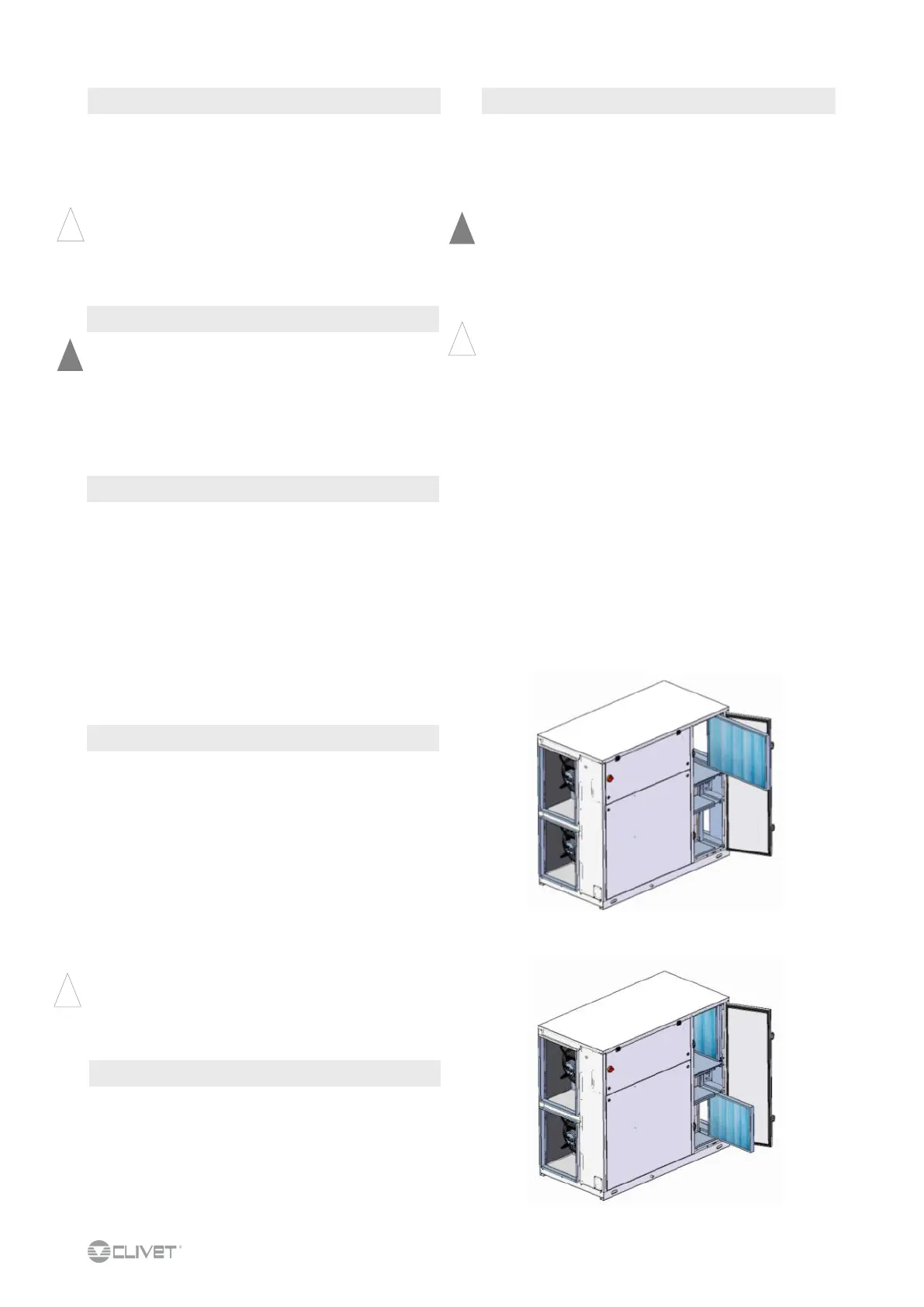

It is very important for the air treatment coil to offer maximum

thermal exchange: the unit must always work with clean and

installed filters. Cleaning and replacement of filters are very

important from an hygienic-sanitary point of view.

Operation with clogged filters leads to a reduction in the air

flow rate with malfunctionings and block, up to possible breaks

in the unit.

The frequency with which the filters must be checked depends

on the quality of the outdoor air, the unit operation hours, the

dustiness and crowding of rooms.

Frequency can indicatively vary from WEEKLY to MONTHLY.

It is advised to start with frequent checks, subsequently

adjusting frequency to degree of detected dirt.

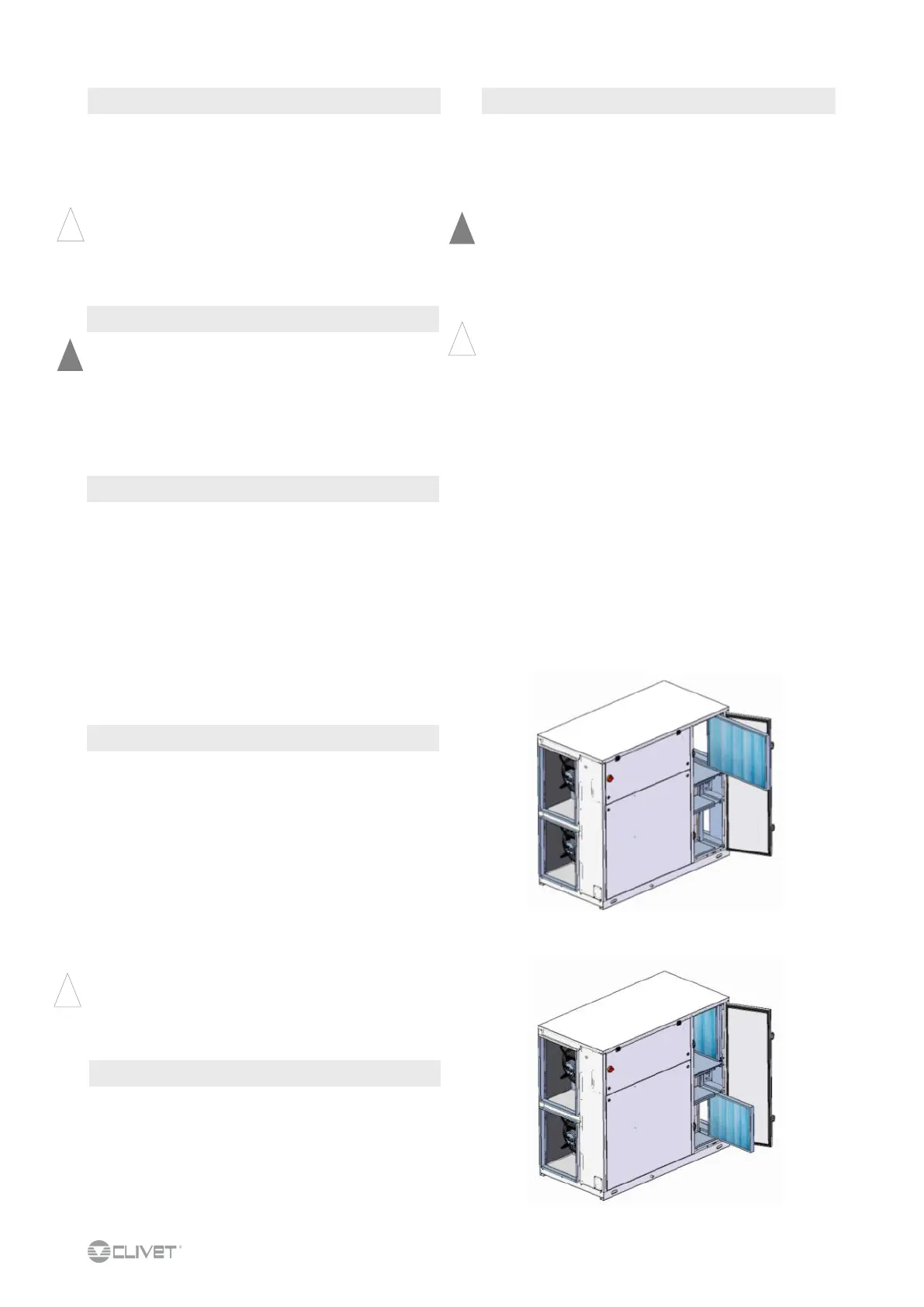

1. Remove the closing panels

2. Delicately remove the filter avoiding dirtying the area

below

3. Wash the filtering jacket in warm water with common

detergent

4. Accurately rinse in running water avoiding spilling in

the room

5. Dry the filter

6. Insert it back in its seat

7. Remount the closing panels

Old filters, washing wastewater and residues must be

disposed of according to the current standards.

9.7 G4 Folded air filters

Loading...

Loading...