44

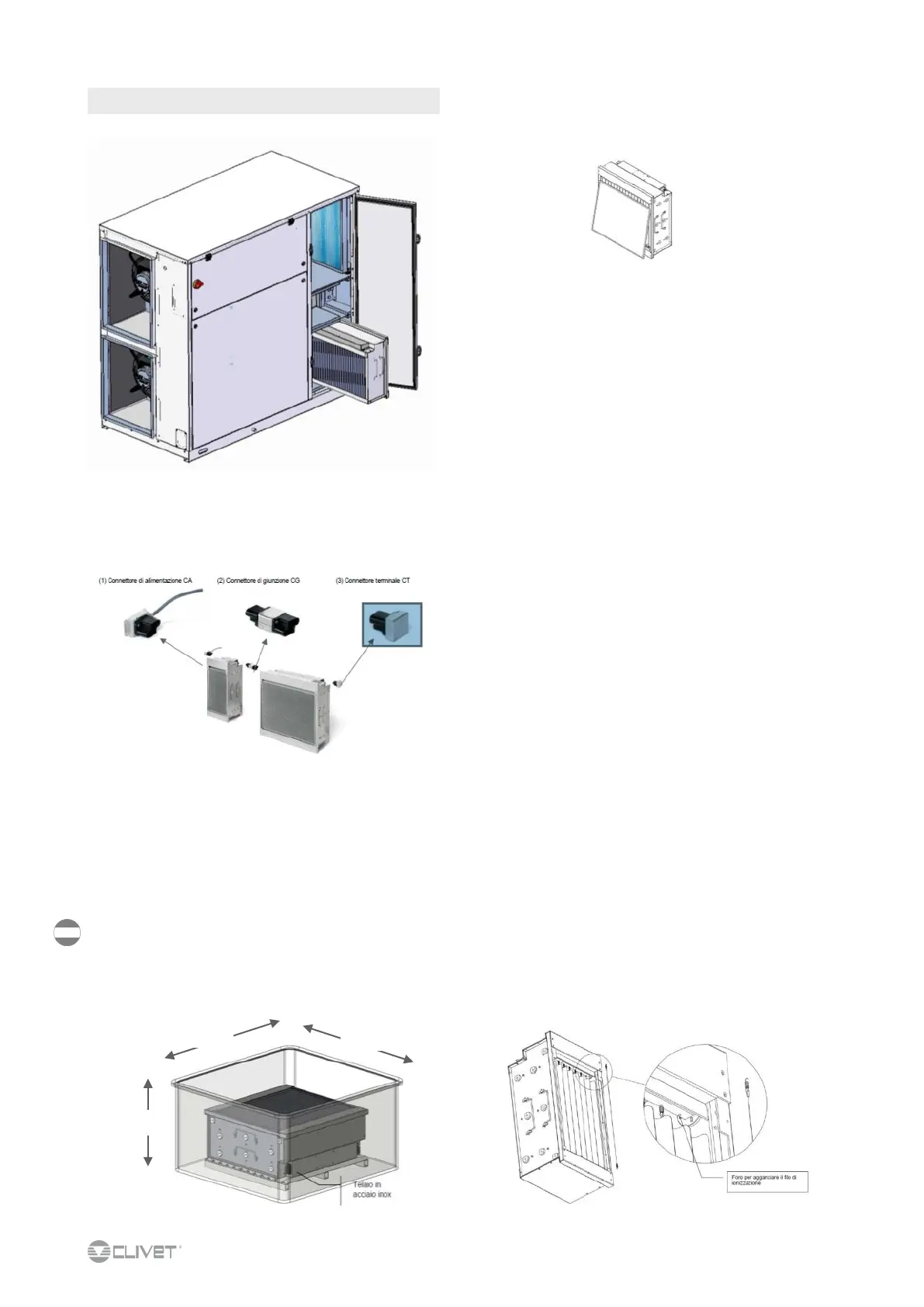

9.8 Filtri elettronici - opzione

La regolazione elettronica è integrata nel filtro; la

manutenzione può essere effettuata senza rimuoverla .

750

750

310

9 - MAINTENANCE

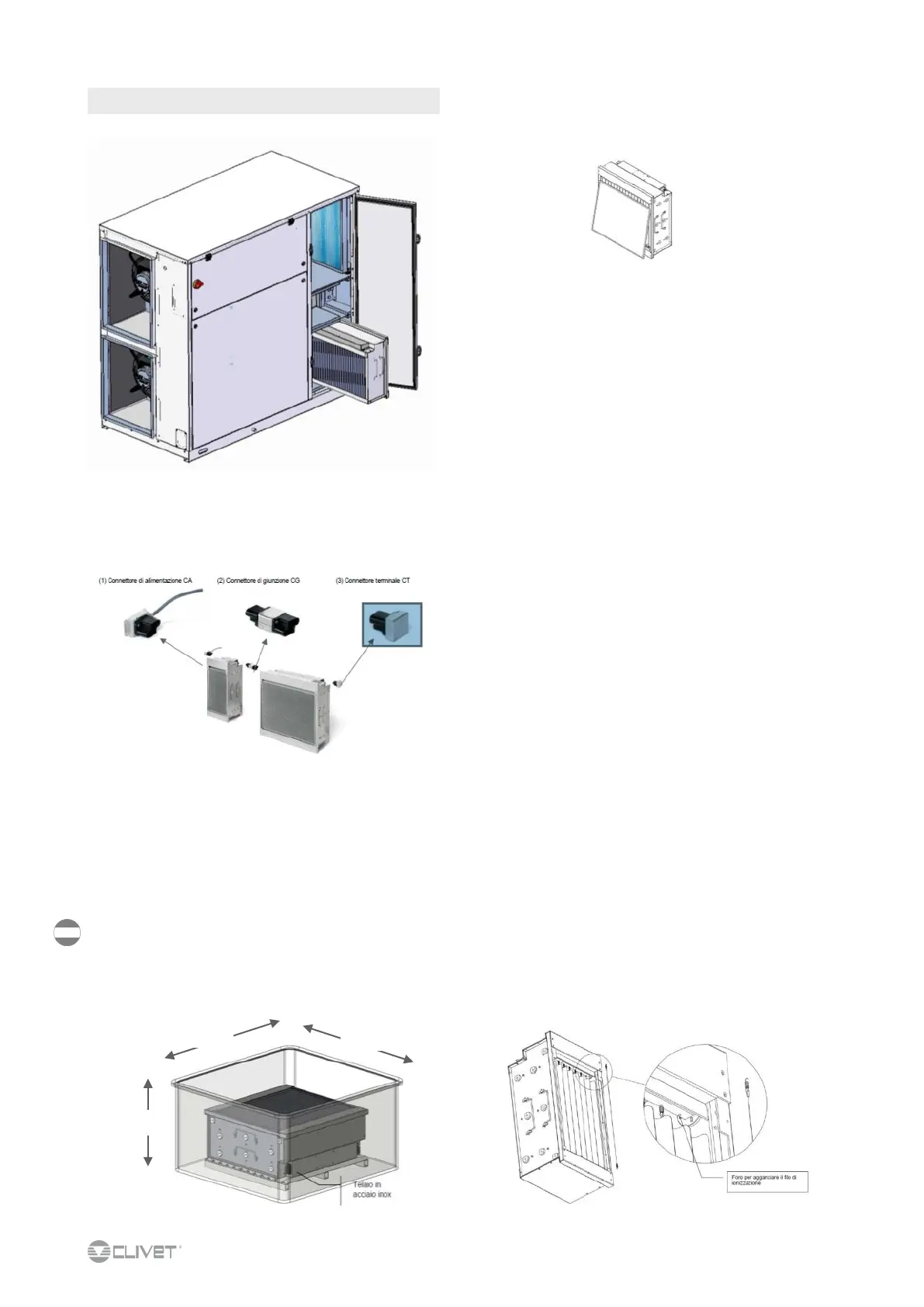

MATERIALS NECESSARY FOR MAINTENANCE

1. Acid detergent B01212 (code CLIVET C6460316)

2. plastic or steel tank (750x750x310 mm) with settling

bottom

3. Protective gloves and goggles

4. Graduated jug;

5. Pump for manual or pneumatic spraying.

Do not use aluminum tanks or galvanized.

Foresee a stainless steel frame that keeps the filters lifted

from the tank base to have a settling bottom for the muds.

Remove the pre-filter by lifting it of about 1 cm and remove it

as shown in figure.

1. Position the filter to be washed on a support to facilitate

work.

2. Prepare a tank with a solution of B01212 detergent and

water at 1÷20.Do not use galvanised steel sheet or

aluminium tanks.

3. Immerse the filter in this solution

4. Ensure the solution covers the entire filter

5. Immerse it for about 5-7 minutes. A slight chemical

reaction is noticed within 2÷3 minutes with the

development of foam indicating the occurred elimination of

residues.

6. Rinse the filter with a jet of water or using a low-pressure

water jet machine.

7. Leave the electrostatic cells to dry in a hot room or directly

in the sun for a few hours.Keep the cells lifted from the

ground using two metal or wooden laths.

Check the ionisation wires before remounting the filter.

The cleaner can be used to clean about 20 filters.

Can be recovered and placed in plastic containers closed; the

air oxidizes the cleaner and reduces its effectiveness.

IONISATION WIRES

The impurities can determine oxidation or scaling on the

wires, which can be removed using a cloth soaked in alcohol

or an abrasive scourer with very fine grain.

Due to the high voltage powering them, the ionisation wires

are subject to wear.

To foresee a yearly replacement OF ALL WIRES avoids

unexpected breaks.

In case of break: :

1. remove all wire pieces present in the cell and remove the

springs stretching the wire;

2. hook the spring to the wire eyelet;

3. grip the ionisation wire with curved beaks pliers;

4. hook the top of the spring with the open eyelet to the wire

stretcher rod of the electrostatic cell;

5. keeping the ionisation wire stretched, with the other hand

hook it to the other wire stretching rod, always by means

of the curved beaks pliers.

Loading...

Loading...