9

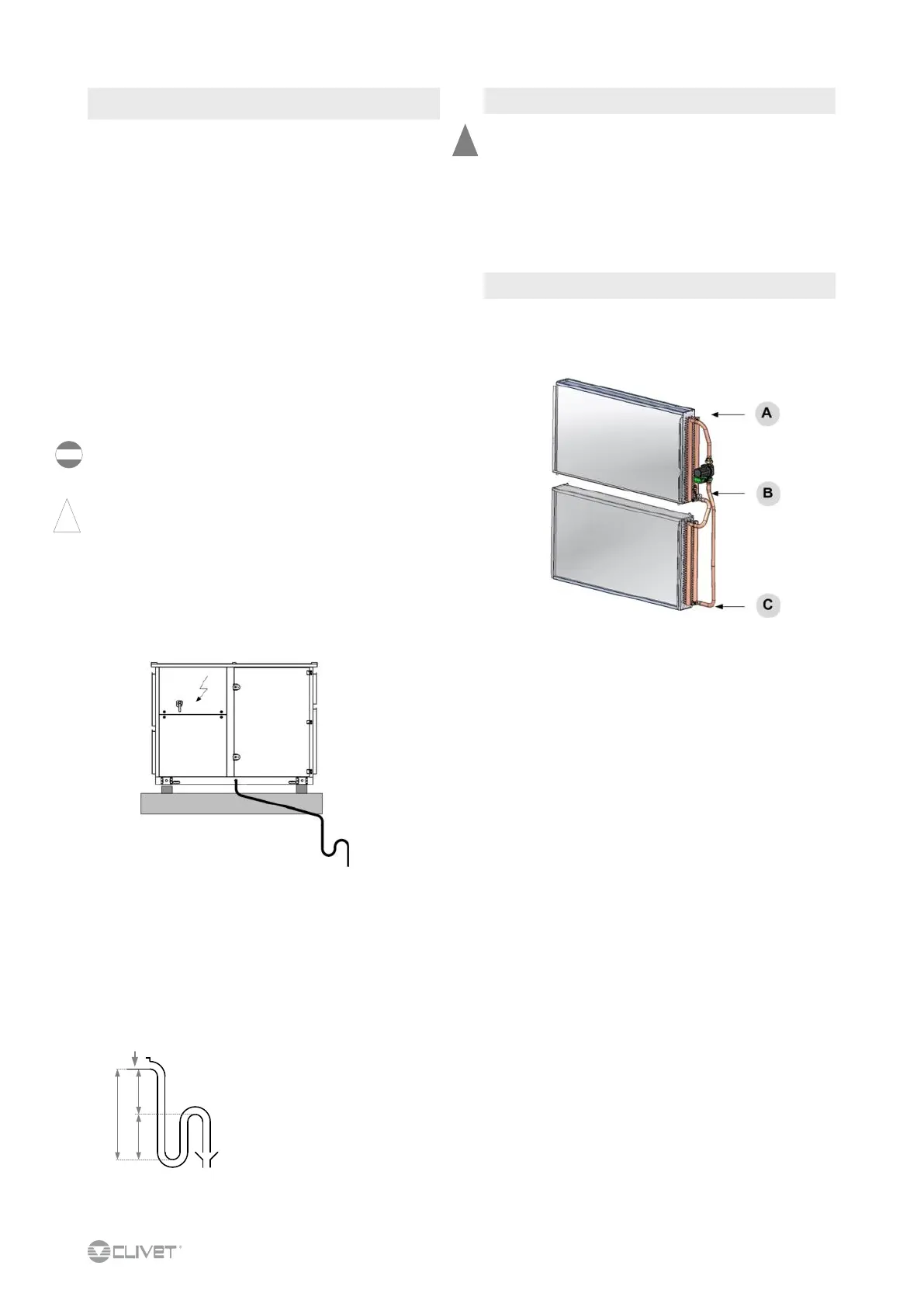

4.3 Hydronic recovery - option

A. vent

B. filling glycol

C. water filling tap

The device is shipped filled with water and glycol.

Adopt measures to prevent risk of freezing if the unit or

relative hydraulic connections can be subject to temperatures

near 0°C.

isolate the piping

protect the piping with heating cables laid underneath

the insulation

4.2 Risk of freezing

4 - HYDRAULIC CONNECTIONS

4.1 Condensate drain

The condensate must be disposed of in order to avoid

damaging things and persons.

Unit drain coupling: the connection must not transmit

mechanical stresses and must be carried out paying

attention not to damage the unit drain coupling.

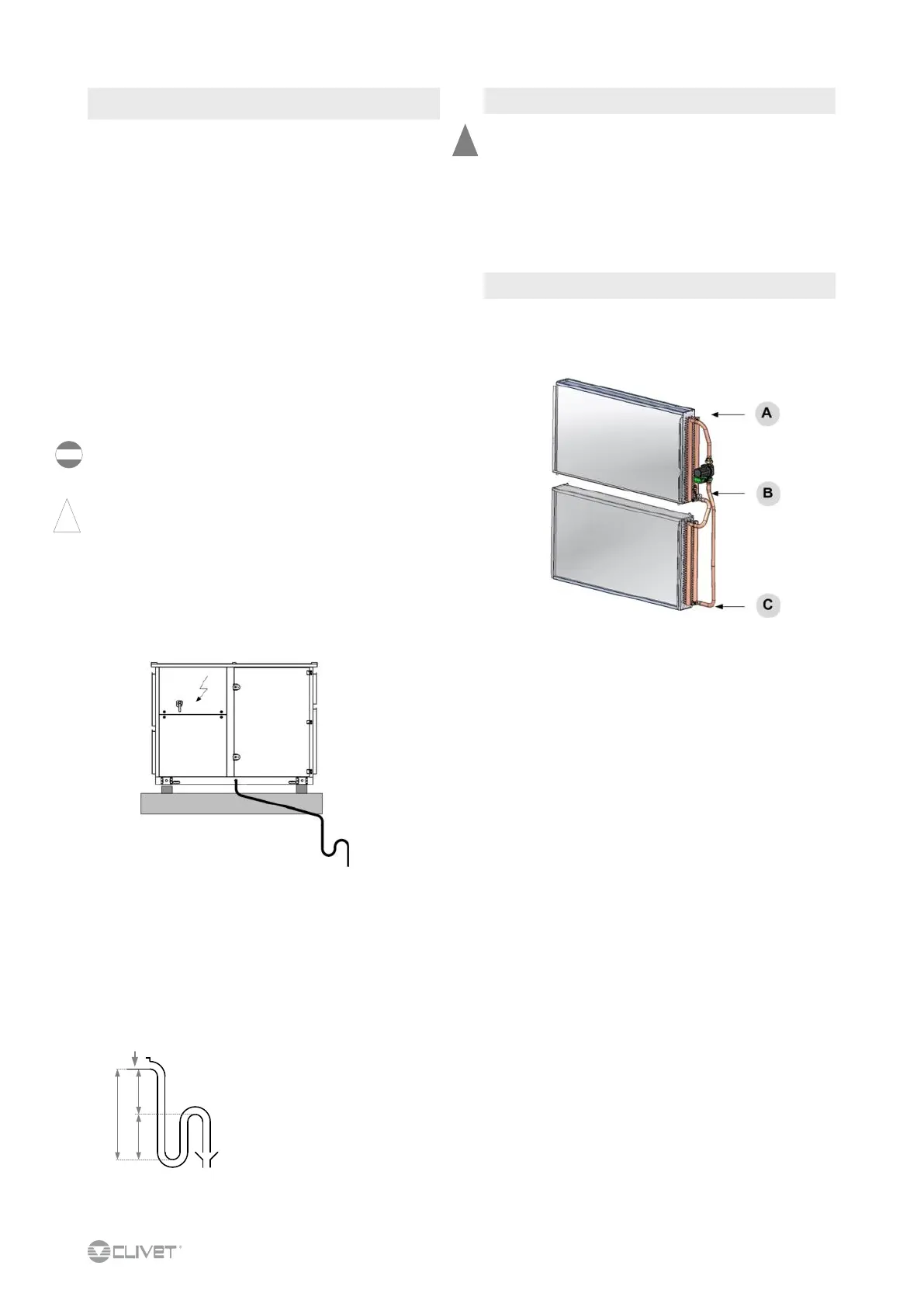

Foresee a siphon that, by eliminating the depression

caused by the fan, prevents suction of air from the drain

piping.

The piping must have adequate slope to allow out flow.

Anchor the piping with an adequate number of supports.

On the contrary, cracking in the piping and air pockets

obstructing the outflow, are generated.

Isolate piping and siphon to avoid condensate dripping.

Connect the condensate drain to a rain drain network.

DO NOT use white waters or sewage drains to avoid

possible inhaling of odours in case of evaporation of the

water contained in the si phon.

At work end, check the regular outflow of the condensate

by pouring water in the bowl.

Example :

P = 300 Pa = 30 mm

T = 2P = 60 mm

S = T/2 = 30 mm

Siphon height calculation

T = 2P

S = T/2

P is the pressure determined by the fan in correspondence of

the condensate collection bowl (approx. 1 mm = 9.81 Pa)

Loading...

Loading...