06

4.4 General Precautions about the Water System

Check the following items before continuing installation:

Min. water pressure: 1 bar

Max. water pressure: 3 bar

Min. water temperature: 5°C

Max. water temperature: 80 °C

Install enough safety devices in the water loops to ensure that the hydro pressure does not exceed the maximum operating

pressure (3 bar).

Provide a drainage hole at all the low points of the system so that the water is completely drained from the water system

when you repair or maintain the unit. A drain valve has been installed at the water inlet to facilitate water discharge from the

unit's water system.

Ensure that you have provided a suitable water discharge pipe to the safety valve to prevent water from coming into contact

with any electrical part. A water discharge pipe has been provided with the unit.

You must deploy air outlets at all the high points of the system. The air outlets should be deployed at the places where they

can be easily maintained. A drain valve has been installed at the water outlet to facilitate air discharge from the unit's water

system.

Ensure that all the components installed on pipes on site can bear water pressure and water temperature.

You should use materials that are compatible with water and equipment in the system.

Anti-freezing protection of the water system:

Freezing may cause damage to the system. The ODU may be exposed to temperatures below 0 °C. You must prevent

the system from freezing.

All the internal water systems are insulated to prevent heat loss. On site, pipes should be fitted with insulating materials.

The unit is designed with an anti-freezing function. The unit uses a heat pump to prevent the entire system from freezing.

When the water temperature in the system decreases to a certain value, the unit will heat water. The anti-freezing

function will be disabled only when the water temperature rises to a certain value.

In the event of power failure, the anti-freezing function cannot protect the unit from freezing.

Using anti-freezing liquid in the water system is recommended, because power failure may happen when no one is

present.

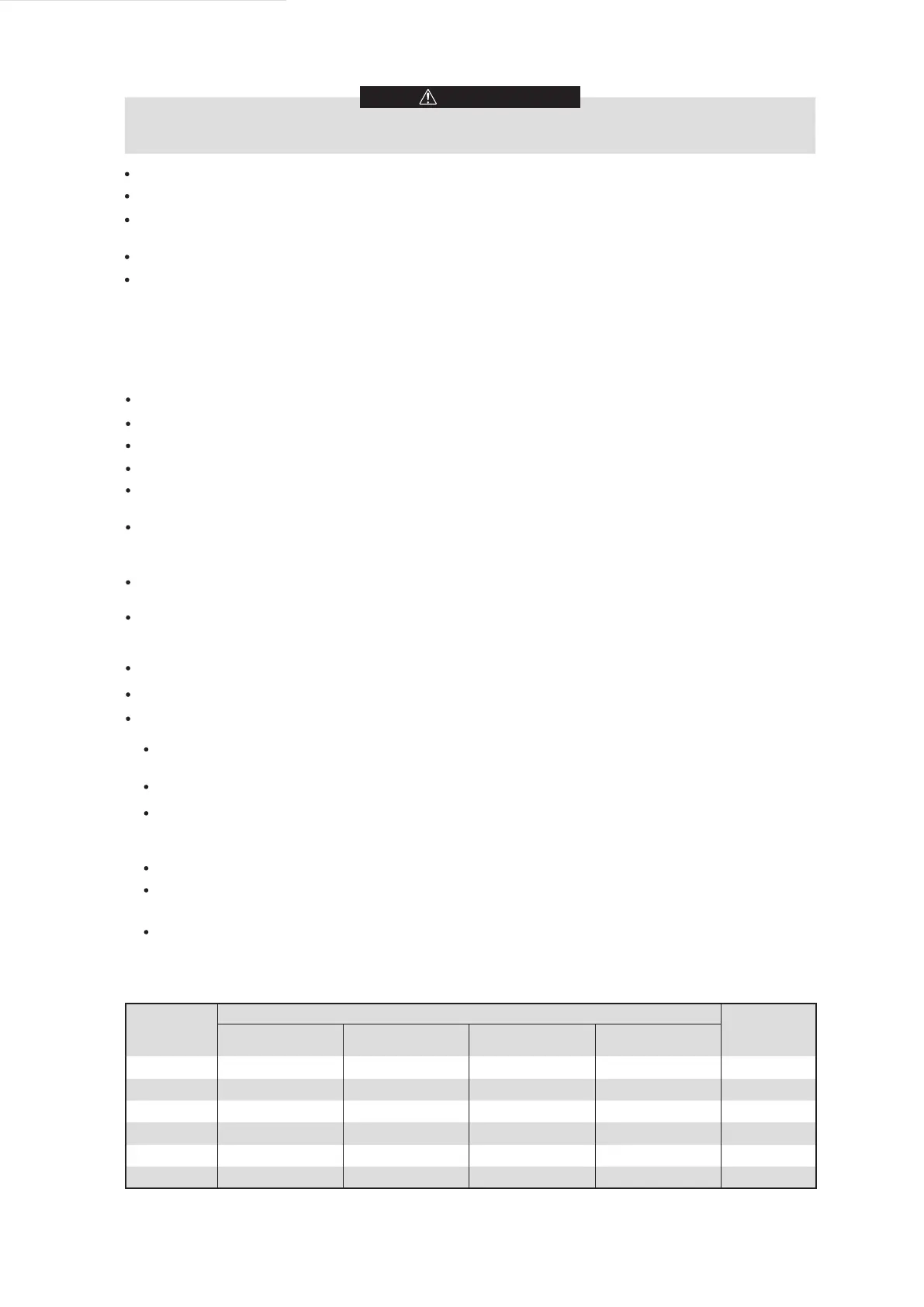

Ensure that the water system is full of the ethylene glycol concentration provided in the following table, according to the

expected lowest outdoor temperature. When ethylene glycol is added to the system, device performance will be affected.

The following table lists the correction coefficients of the unit capacity, flow, and pressure drop of the system.

WARNING

In an airtight space, excessively high concentration of the refrigerant may lead to insufficient oxygen.

Do not climb, sit on, or stand on the unit.

Do not place any article or equipment on the top of the unit (top panel of the unit).

Do not install the unit in a workshop, for example, a construction site, because at construction sites, the equipment will be

covered in dust.

Do not install the unit in a highly damp site, such as a restroom. (The maximum relative humidity is 85%.)

When installing the unit, reserve enough space for the air inlet and air outlet. Do not obstruct them.

Ethylene Glycol

Quality of

glycol/%

0

10

20

30

40

50

1.000

0.984

0.973

0.965

0.960

0.950

1.000

0.998

0.995

0.992

0.989

0.983

1.000

1.118

1.268

1.482

1.791

2.100

1.000

1.019

1.051

1.092

1.145

1.200

0.000

-4.000

-9.000

-16.000

-23.000

-37.000

Freezing

point/°C

Cooling capacity

modification

Power

modification

Water

resistance

Water flow

modification

Modification coefficient

Loading...

Loading...