F80CTL & G80CTL: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

16

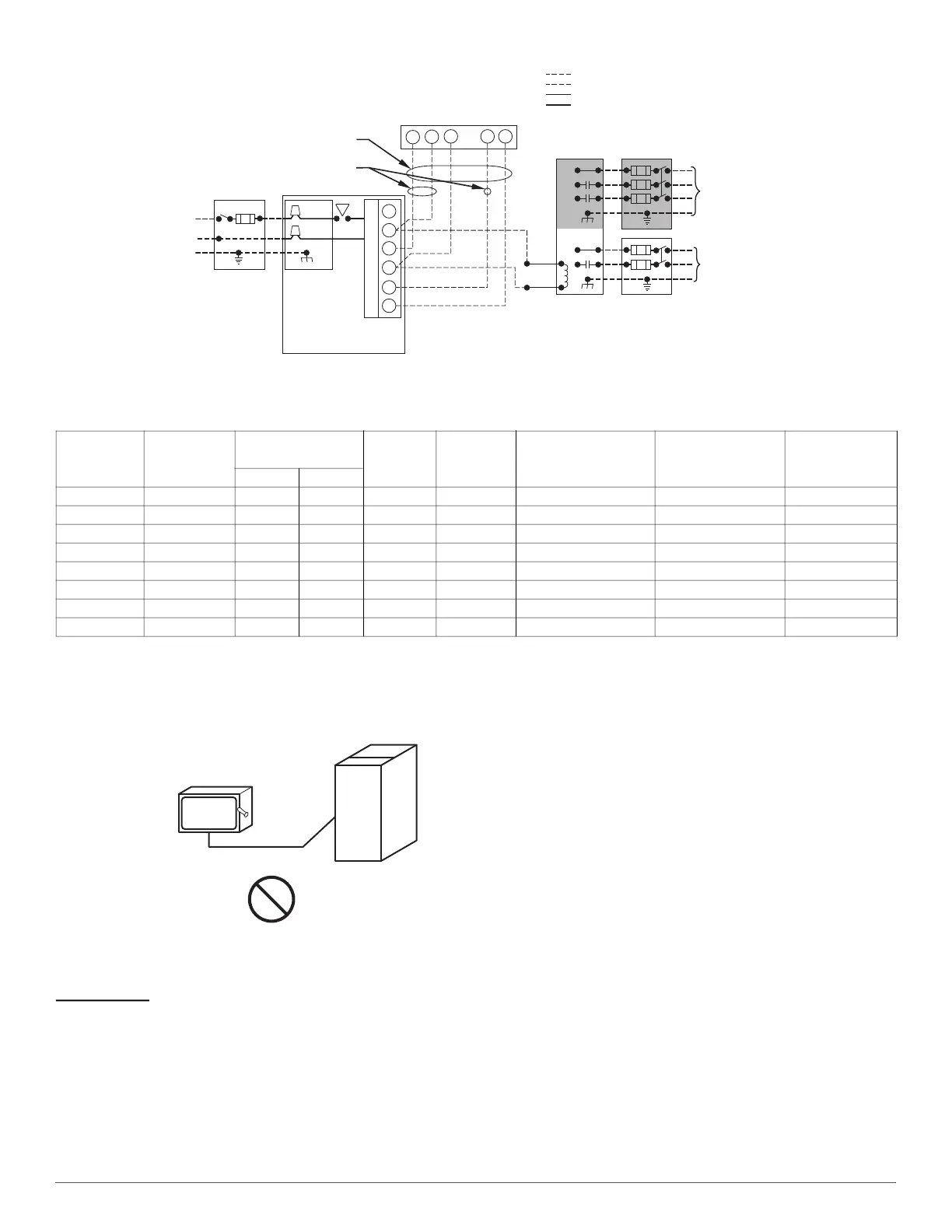

A95236

Fig. 24 – Field Wiring Diagram

A190279

Fig. 25 – Field-Supplied External

Electrical Box on Furnace Casing

115-V Wiring

Verify that the voltage, frequency, and phase correspond to that specified

on unit rating plate. Also, check to be sure that service provided by

utility is sufficient to handle load imposed by this equipment. Refer to

rating plate or Table 5 for equipment electrical specifications.

U.S. Installations: Make all electrical connections in accordance with

National Electrical Code (NEC) NFPA 70 and any local codes or

ordinances that might apply.

Use a separate, fused branch electrical circuit with a properly sized fuse

or circuit breaker for this furnace. See Table 5 for wire size and fuse

specifications. A readily accessible means of electrical disconnect must

be located within sight of the furnace.

NOTE: Proper polarity must be maintained for 115-v wiring. If polarity

is incorrect, control LED status indicator light will flash status code 10

and furnace will NOT operate.

J-BOX RELOCATION

NOTE: If factory location of J-Box is acceptable, go to next section

(ELECTRICAL CONNECTION to J-Box).

NOTE: On 14-in. (356 mm) wide casing models, the J-Box shall not be

relocated to other side of furnace casing when the vent pipe is routed

within the casing.

1. Remove and save two screws holding J-Box, see Fig. 26.

NOTE: The J-Box cover need not be removed from the J-Box in order

to move the J-Box. Do NOT remove green ground screw inside J-Box,

see Fig. 26.

2. Cut wire tie on loop in furnace wires attached to J-Box.

3. Move J-Box to desired location.

4. Fasten J-Box to casing with the two screws removed in Step 1.

5. Route J-Box wires within furnace away from sharp edges, rotating

parts and hot surfaces.

Table 5 – Electrical Data

FURNACE

SIZE

VOLTS-

HERTZ-

PHASE

OPERATING

VOLTAGE RANGE

*

*. Permissible limits of the voltage range at which the unit operates satisfactorily.

MAX.

UNIT

AMPS

UNIT

AMPACITY

†

†. Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier, etc.) full load

amps.

MAX. WIRE LENGTH

- FT (M)

‡

‡. Length shown is as measured 1 way along wire path between furnace and service panel for maximum 2 percent voltage drop.

MAX. FUSE OR CKT

BKR AMPS

**

**. Time-delay type is recommended.

MIN. WIRE

GAUGE

Max. Min.

0451712 115-60-1 127 104 9.0 12.0 30 (9.4) 15 14

0701412 115-60-1 127 104 9.0 12.0 30 (9.4) 15 14

0701716 115-60-1 127 104 9.0 13.0 28 (8.7) 15 14

0702120

115-60-1 127 104 14.1 18.4 31 (9.5) 20 12

0901716

115-60-1 127 104 9.6 12.63 29 (9.0) 15 14

0902120

115-60-1 127 104 14.7 19.0 30 (9.2) 20 12

1102120 115-60-1 127 104 15.0 19.3 29 (9.1) 20 12

1352422

115-60-1 127 104 15.0 19.3 29 (9.1) 20 12

115-VOLT FIELD-

SUPPLIED

FUSED

DISCONNECT

JUNCTION

BOX

CONTROL

BOX

24-VOLT

TERMINAL

BLOCK

THREE-WIRE

HEATING-

ONLY

FIVE

WIRE

NOTE 2

NOTE 1

1-STAGE

THERMOSTAT

TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

FURNACE

COM

R

WCY RG

GND

GND

FIELD 115-, 208/230-, 460-VOLT WIRING

FACTORY 24-VOLT WIRING

FACTORY 115-VOLT WIRING

Connect Y/Y2-terminal as shown for proper operation.

Some thermostats require a "C" terminal connection as shown.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

208/230- O

460-VOLT

THREE

PHASE

208/230-

VOLT

SINGLE

PHASE

HT

BLK

WHT

BLK

W/W1

W2

Y/Y2

G

NOTES: 1.

2.

3.

COPPER

WIRE ONLY

ELECTRIC

DISCONNECT

SWITCH

ALUMINUM

WIRE

Loading...

Loading...