F80CTL & G80CTL: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

22

such products in the combustion-air supply. Furnace use during

construction of the building could cause the furnace to be exposed to

halogen compounds, causing premature failure of the furnace or venting

system due to corrosion.

Vent dampers on any appliance connected to the common vent can cause

condensation and corrosion in the venting system. Do not use vent

dampers on appliances common vented with this furnace.

Additional Venting Requirements

A 4-in. (102 mm) round vent elbow is supplied with the furnace. A 5-in.

(127 mm) or 6- in. (152 mm) vent connector may be required for some

model furnaces. A field-supplied 4-in. (102 mm) to 5-in. (127 mm) or

4-in. (102 mm) to 6-in. (152 mm) sheet metal increaser fitting is required

when 5-in. (127 mm) or 6-in. (152 mm) vent connector is used. Refer to

Table 8 to determine the minimum vertical vent height for various

furnace and vent orientations. See Fig. 34- Fig. 46 Venting Orientation

for approved vent configurations.

NOTE: Vent connector length for connector sizing starts at furnace vent

elbow. The 4-in. (102 mm) vent elbow is shipped for upflow

configuration and may be rotated for other positions. Remove the three

screws that secure vent elbow to furnace, rotate furnace vent elbow to

position desired, reinstall screws. The factory-supplied vent elbow does

NOT count as part of the number of vent connector elbows.

The vent connector can exit the furnace through one of five locations on

the casing.

1. Attach the single wall vent connector to the furnace vent elbow, and

fasten the vent connector to the vent elbow with at least two

field-supplied, corrosion-resistant, sheet metal screws located 180°

apart.

NOTE: An accessory flue extension is available to extend from the

furnace elbow to outside the furnace casing. See Specification Sheet for

accessory listing. If flue extension is used, fasten the flue extension to

the vent elbow with at least two field-supplied, corrosion-resistant, sheet

metal screws located 180° apart. Fasten the vent connector to the flue

extension with at least two field-supplied, corrosion resistant sheet metal

screws located 180° apart.

2. Vent the furnace with the appropriate connector, see

Fig. 34 - Fig. 46.)

3. Determine the correct location of the knockout to be removed.

4. Use a hammer and screwdriver to strike a sharp blow between the

tie points and work the slug back and forth until the slug breaks

free.

An accessory Vent Guard Kit is REQUIRED for downflow applications

for use where the vent exits through the lower portion of the furnace

casing. Refer to the Vent Guard Kit Instructions for complete details. See

Specification Sheet for accessory listing.

The horizontal portion of the venting system shall slope upwards not less

than 1/4-in. per linear ft. (21 mm/m) from the furnace to the vent and

shall be rigidly supported every 5 ft. (1.5 M) or less with metal hangers

or straps to ensure there is no movement after installation.

Sidewall Venting

This furnace is not approved for direct sidewall horizontal venting.

Per section 12.4.3 of the NFPA 54/ANSI Z223.1, any listed mechanical

venter may be used, when approved by the authority having jurisdiction.

Select the listed mechanical venter to match the Btuh input of the

furnace being vented. Follow all manufacturer’s installation

requirements for venting and termination included with the listed

mechanical venter.

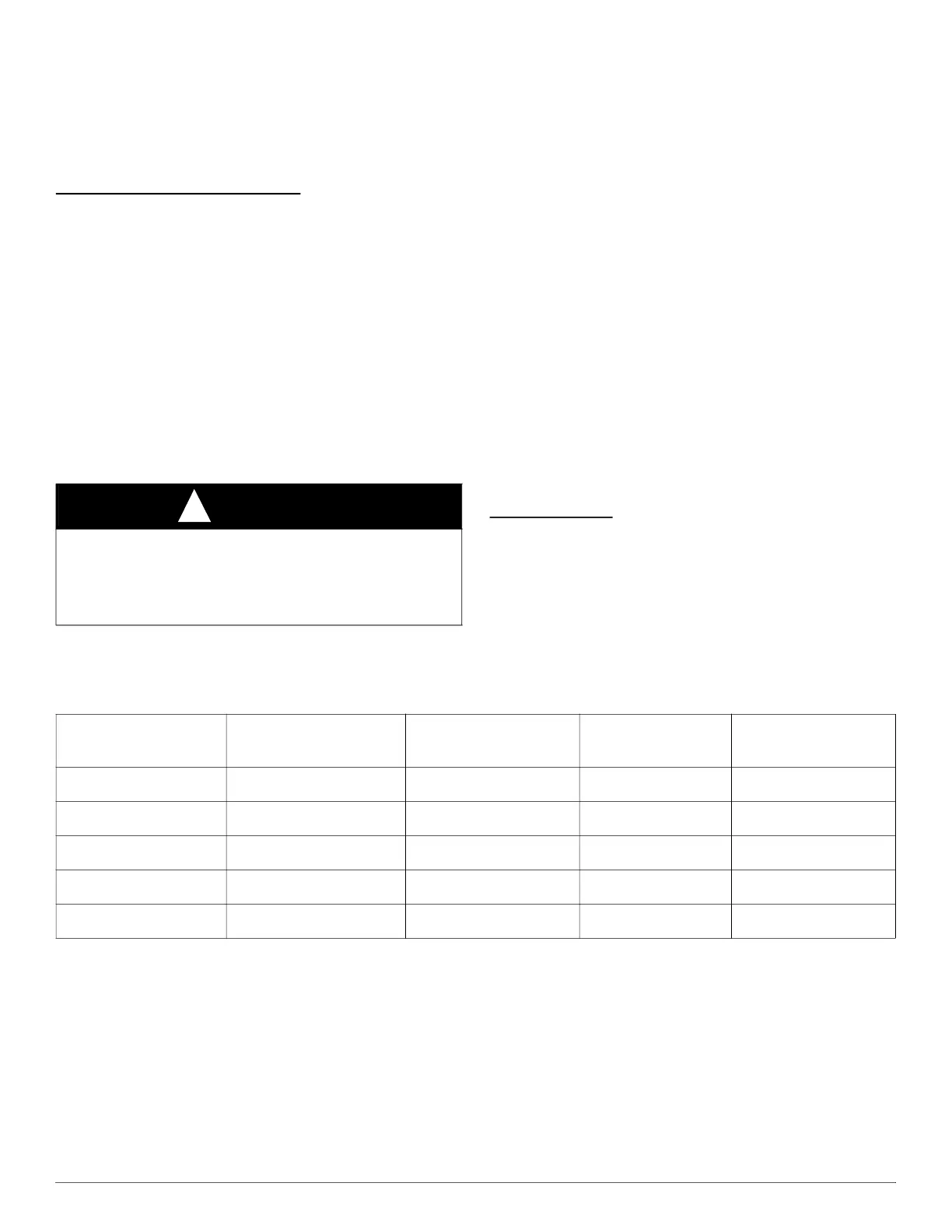

Caution!! For the following furnace and vent orientations, use the minimum vertical heights as specified in Table 8.

For all other orientations, follow exclusively the National Fuel Gas Code.

NOTE: All vent configurations must also meet National Fuel Gas Code venting requirements NFGC.

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing, safety glasses and gloves when

handling parts, and servicing furnaces.

Table 8 – Recommended Minimum Vent Height Per Furnace and Vent Orientation

FURNACE

ORIENTATION

VENT ORIENTATION

FURNACE INPUT

(BTUH/HR)

MIN. VENT

DIAMETER

IN. (mm)

*

*. 4-in. (102 mm) inside casing or vent guard

MIN. VERTICAL VENT

HEIGHT

FT. (M)

†

†. Including 4 in. (102 mm) vent section(s)

Downflow

Vent elbow left, then up

Fig. 39

132,000 & 110,000 5 (127) 12 (3.6)

Horizontal Left

Vent elbow right, then up

Fig. 42

132,000 5 (127) 7 (2.1)

Horizontal Left

Vent Elbow up

Fig. 43

132,000 5 (127) 7 (2.1)

Downflow

Vent elbow up then left

Fig. 35

110,000 5 (127) 10 (3.0)

Downflow

Vent elbow up, then right

Fig. 40

110,000 5 (127) 10 (3.0)

Loading...

Loading...