F80CTL & G80CTL: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

28

NOT forget to return setup switch to OFF position and remove jumper

upon completion of testing.

c. This furnace is capable of automatically providing proper airflow

to maintain the temperature rise within the range specified on

furnace rating plate. If temperature rise is outside this range,

proceed as follows:

(1.) Check gas input for low- and high-heat operation.

(2.) Check derate for altitude if applicable.

(3.) Check all return and supply ducts for excessive restrictions

causing static pressure greater than 0.5-In. W.C.

(4.) Ensure setup switch SW1-4 (Comfort/Efficiency) is in

OFF=Efficiency position when a bypass humidifier is used,

see Fig. 32 for switch location.)

(5.) Make sure proper model plug is installed.

d. Remove thermostat jumpers and release blower access door

switch.

e. Repeat Steps a through c as required to adjust for high heat

temperature rise.

f. When correct high heat input rate and temperature rise is

achieved, turn gas valve ON/OFF switch to OFF.

g. Release blower access door switch.

h. Remove manometer or similar device from gas valve.

i. Re-install manifold pressure tap plug in gas valve, see Fig. 21.

j. Remove thermostat jumper wire from furnace control board.

k. Turn gas valve ON/OFF switch to ON.

l. Proceed to Step 7, “Set Blower Off Delay” before installing

blower access door.

7. Set Blower Off Delay

a. Remove blower access door if installed.

b. Turn Dip switch SW-7 or SW-8 ON or OFF for desired blower

off delay, see Table 11, Table 14, Fig. 32, and Fig. 53.

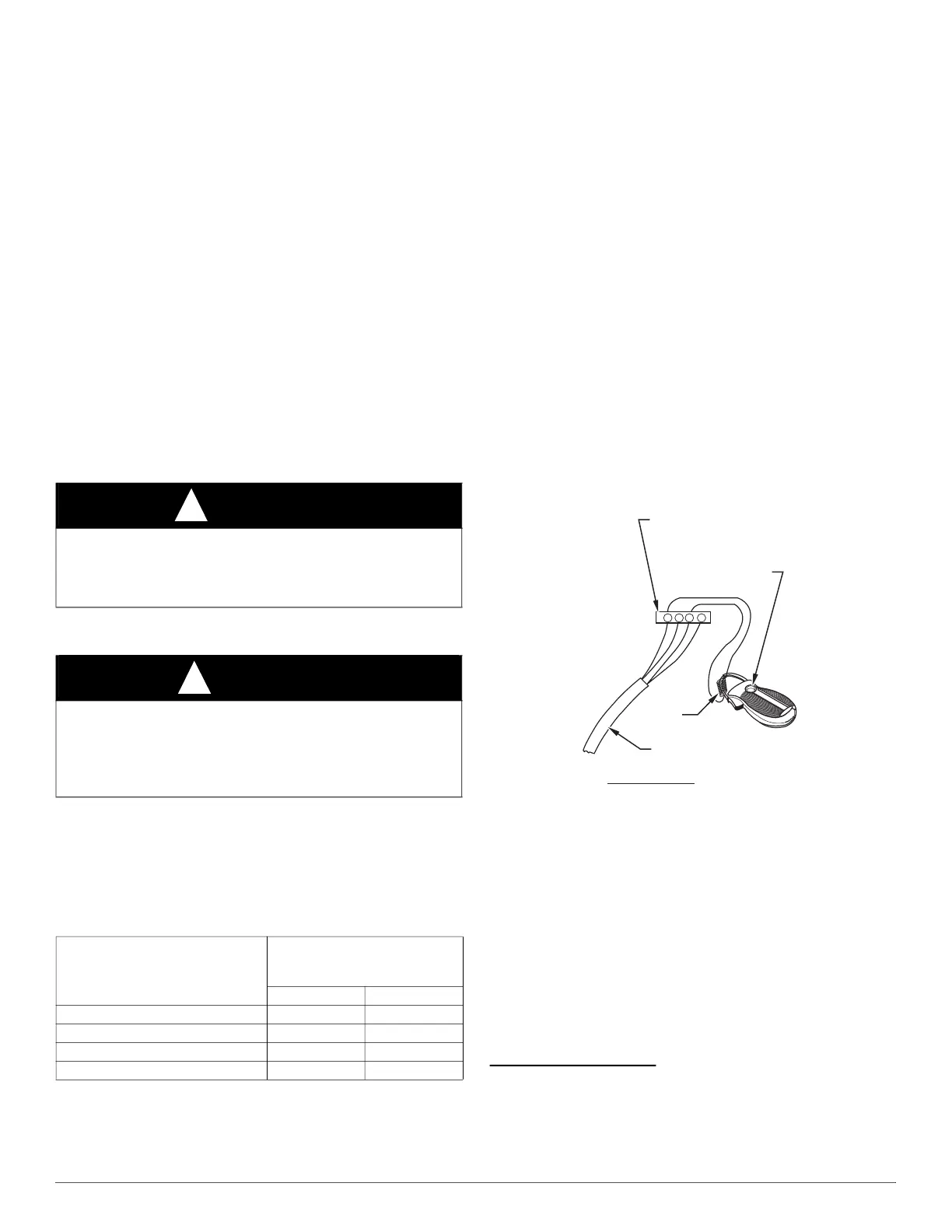

8. Set thermostat heat anticipator.

a. Mechanical thermostat. Set thermostat heat anticipator to match

the amp. draw of the electrical components in the R-W/W1

circuit. Accurate amp. draw readings can be obtained at the wires

normally connected to thermostat subbase terminals, R and W.

The thermostat anticipator should NOT be in the circuit while

measuring current.

(1.) Set SW1-2 switch on furnace control board to ON.

(2.) Remove thermostat from subbase or from wall.

(3.) Connect an amp. meter across the R and W subbase

terminals or R and W wires at wall, see Fig. 48.

(4.) Record amp. draw across terminals when furnace is in low

heat and after blower starts.

(5.) Set heat anticipator on thermostat per thermostat

instructions and install on subbase or wall.

(6.) Turn SW1-2 switch OFF.

(7.) Install blower access door.

b. Electronic thermostat: Set cycle rate for 3 cycles per hr.

9. Set Airflow for Air Conditioning -Single Stage and High Stage

Cooling

The ECM blower can be adjusted for a range of airflow for Low

Speed or High Speed cooling. See Table 13-Air Delivery - CFM

(With Filter). Depending on the model size, the cooling airflow can

be adjusted from 1.5 to 6 tons based on 350 CFM/ton. Refer to

Table 12.

The cooling airflow is adjusted by turning Setup switches SW2-1,

SW2-2 and SW2-3 either ON or OFF. Select the required airflow,

see Fig. 14. Fig. 14 is based on 350 CFM per ton. For airflow at 400

CFM per ton, turn Setup SW1-5 ON, see Table 11, Table 14,

Fig. 32, and Fig. 53.

A96316

Fig. 48 – Amp. Draw Check with Ammeter

NOTE: 5.5 ton airflow will truncate at 2200 cfm on applicable models.

For a complete explanation of cooling airflow, refer to the section titled

“Sequence of Operation.”

Set Airflow For Continuous Fan/Low Speed Cooling Airflow The ECM

blower motor can be adjusted for continuous fan speeds different than

heating or cooling fan speed. See Table 13 - Air Delivery - CFM (With

Filter). Select the required continuous fan airflow, see Fig. 14.

The continuous fan speed is also the switch setting for low speed cooling

when furnace is used with a 2-speed cooling unit. Adjust the Continuous

Fan CFM to match the airflow required for low speed cooling. Select the

required airflow, see Fig. 50. For airflow at 400 CFM per ton, turn Setup

SW1-5 ON, see Fig. 14. The airflow selected for low speed cooling will

also be the airflow used for continuous fan.

Check Safety Controls

The flame sensor, gas valve, and pressure switch were all checked in the

Start-up procedure section as part of normal operation.

1. Check Main Limit Switch

This control shuts off combustion system and energizes

air-circulating blower motor, if furnace overheats. By using this

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Reinstall manifold pressure tap plug in gas valve to prevent gas leak.

CAUTION

!

FURNACE OVERHEATING HAZARD

Failure to follow this caution may result in reduced furnace life.

Recheck temperature rise. It must be within limits specified on the

rating plate. Recommended operation is at the mid-point of rise range

or slightly above.

Table 11 – Blower Off Delay Setup Switch

DESIRED HEATING MODE

BLOWER OFF DELAY (SEC.)

SETUP SWITCH

(SW-7 AND -8)

POSITION

SW1-7 SW1-8

90 OFF OFF

120 ON OFF

150 OFF ON

180 ON ON

R Y W G

10 TURNS

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

(ANITICIPATOR, CLOCK, ETC.,

MUST BE OUT OF CIRCUIT.)

HOOK-AROUND

AMMETER

EXAMPLE:

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

=

0.5 AMPS FOR THERMOSTAT

ANTICIPATOR SETTING

FROM UNIT 24-V

CONTROL TERMINALS

Loading...

Loading...