F80CTL & G80CTL: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

47

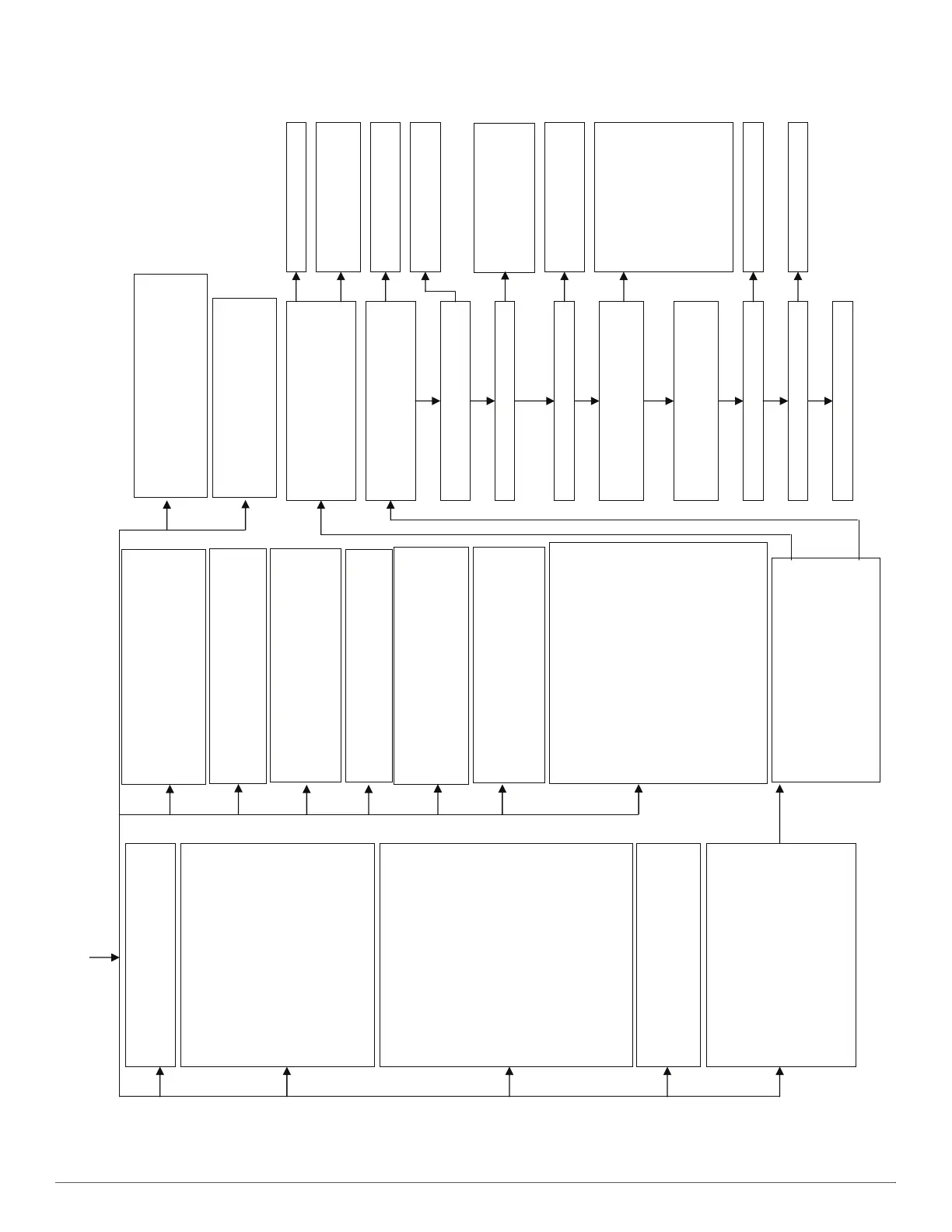

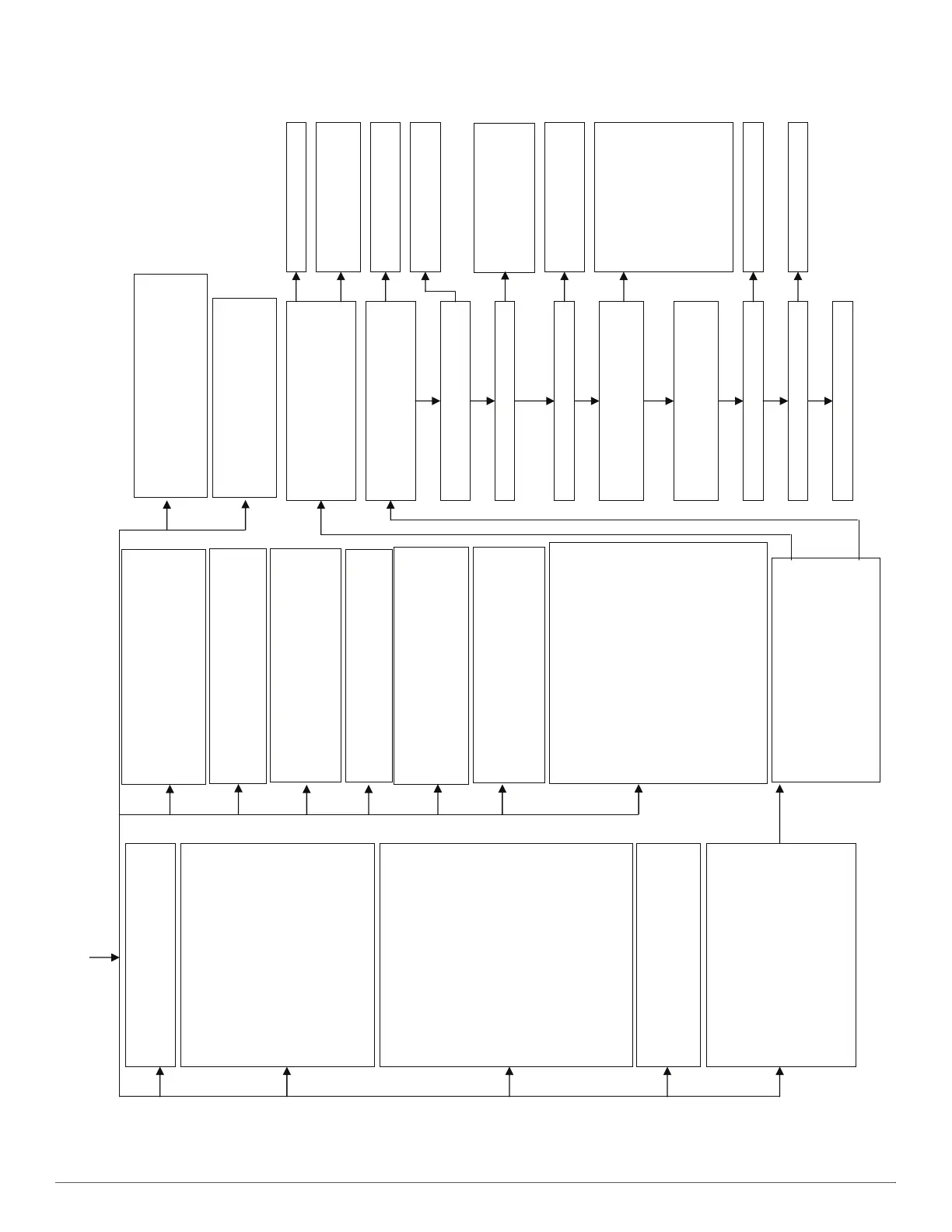

A190159

Fig. 54 – Troubleshooting Guide

1 + 2 BLOWER ON AFTER POWER UP –

(115V OR 24V) – Normal operation.

Blower runs for 90 seconds, if unit is

powered up during a call for heat (R-

W/W1 closed) or when (R-W/W1 opens)

during the blower on-delay period.

6 + 1 IGNITION LOCKOUT – System

failed to ignite gas and prove

flame in 4 attempts. Control will

auto-reset after 3 hours. Refer to

status code #6.

5 ABNORMAL FLAME-PROVING SIGNAL

Flame is proved while gas valve is de-

energized. Inducer will run until fault is

cleared. Check for:

- Stuck open or leaky gas valve.

2 PRESSURE SWITCH DID NOT OPEN –

Check for:

- Obstructed pressure tube.

- Pressure switch stuck closed.

3 LOW-HEAT PRESSURE SWITCH DID

NOT CLOSE OR REOPENED – If opens

during blower on-delay period, blower will

come on for the selected blower off-delay.

If open longer than 5 minutes inducer

shuts off for 15 minutes before retry.

Check for:

- Proper vent sizing.

- Low inlet gas pressure (if LGPS used).

- Inadequate combustion air supply.

- Disconnected or obstructed pressure

tubing.

- Defective or miswired pressure switches

- Excessive wind.

- Restricted vent.

- Defective Inducer motor.

- Low inducer volta

e

115 VAC

4 LIMIT CIRCUIT FAULT – Indicates the

limit, draft safeguard, flame rollout, or

blocked vent switch (if used) is open or the

furnace is operating in high-heat only

mode due to 2 successive low-heat limit

trips. Blower will run for 4 min. or until

open switch remakes whichever is longer.

If open longer than 3 min., code changes

to lockout #7. If open less than 3 min.

status code #4 continues to flash until

blower shuts off. Flame rollout and

blocked vent switch require manual reset.

Check for:

- Restricted vent.

- Loose blower wheel.

- Defective switch or connections.

- Proper vent sizing.

- Dirty filter or restricted duct system.

- Excessive wind.

- Inadequate combustion air supply.

(Flame rollout switch open)

- Blower motor not operating

To determine whether the problem is in the gas

valve, igniter, or flame sensor the system can be

operated in component test mode. To check the

igniter remove the R thermostat connection from

the control, reset power, and put setup switch

SW1-6 in the ON position to start the

component test. Does the igniter glow

orange/white by the end of the 15 second warm-

up period?

Unplug igniter harness from control and

repeat component test by turning setup

switch SW1-6 OFF and then back ON.

Check for 115V between pin 3 and

NEUTRAL-L2 on the control. Was 115V

present for the 15 second period?

Check connections and retry.

If current is near typical value

(4.0-6.0 nominal) and burners

will not stay on, repeat check

in high-heat. If burners will

still not stay on replace

control. If burners operate in

high-heat then switch to low-

heat, check manifold

pressure. If OK, check

burner carryover and flame

sensor location.

Clean flame sensor with fine steel wool

and recheck current. Nominal current is

4.0 to 6.0 microamps.

Is current near typical value?

Replace flame sensor.

Will main burners ignite and stay on? Replace furnace control.

Fixed.

NO

YES

YES

YES

NO

NO

Replace furnace control.

Check for continuity in the

harness and igniter. Replace

defective component.

Reconnect the R thermostat lead and set

thermostat to call for heat. Connect

voltmeter across gas valve connections.

Does gas valve receive 24V?

Does gas valve open and allow gas to

flow?

Do the main burners ignite?

Do the main burners stay on?

Allow blower to come on and

repeat test to check for

intermittent operation.

Check that all gas valves are

turned on. Replace valve.

Check connections. If OK,

replace control.

Check for:

- Inadequate flame carryover

or rough ignition.

- Low inlet gas pressure.

- Proper firing rate.

Repeat call for heat and check flame

sensor current during trial for ignition

period. Is the DC microamps below 0.5?

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

6 IGNITION PROVING FAILURE – If flame is

not sensed during the trial for ignition

period, the control will repeat the ignition

sequence 3 more times before lockout #6 +

1 occurs. If flame signal is lost during the

blower on-delay period, blower will come on

for the selected blower off-delay. Check

the following before going to the next step.

- Gas valve turned off.

- Manual shut-off valve.

- Green/Yellow wire MUST be connected

to furnace sheet metal.

- Flame sensor must not be grounded.

9 HIGH-HEAT PRESSURE SWITCH OR

RELAY DID NOT CLOSE OR REOPENED

Check for:

- Control relay may be defective. - Gas

valve is miswired.

- Refer to status code #3.

10 POLARITY – Check for correct line voltage

polarity. If units are twinned, check for

proper low-voltage (24V) transformer

phasing.

7 LIMIT CIRCUIT LOCKOUT – Lockout

occurs if the limit, draft safeguard, flame

rollout, or blocked vent switch (if used) is

open longer than 3 minutes or 10

successive limit trips occurred during high-

heat. Control will auto-reset after 3 hours.

Refer to status code #4.

8 GAS HEATING LOCKOUT – Control will

NOT auto reset. Turn off power and wait

5 minutes to retry. Check for:

- Stuck closed gas valve relay on control.

- Miswire or short to gas valve wire.

2 + 5 INVALID MODEL SELECTION OR SETUP

ERROR – If status code 2 + 5 only flashes 4

times on power-up the control is missing its

model plug PL4 and is defaulting to the

model selection stored in memory. If status

code 2 + 5 flashes continuously it could

indicate any of the following:

- Model plug PL4 is missing and there is no

valid model stored in permanent memory.

This will happen if you forget to install the

model plug PL4 on a service replacement

control.

- Thermostat call with SW1-1 ON.

- Thermostat call with SW1-6 ON.

- SW1-1 and SW1-6 both ON.

- Two different furnace models twinned.

- If replacing a control, be sure to use

correct version (V##) located on control

board) Models supported should be listed

NOTE:

NUMBER IN UPPER LEFT HAND

CORNER REPRESENTS FLASH CODE

4 + 1 BLOWER MOTOR FAULT –

indicates blower failed to reach 250 RPM

or the blower failed to communicate

within the prescribed time limits. 30

seconds after being turned ON or 10

seconds during steady-safe operation.

1 + 5 BLOWER MOTOR LOCKOUT – Indicates

the blower failed to reach 250 RPM or the

blower failed to communicate within 30 seconds

after being turned ON in 2 successive heating

cycles. Control will auto reset after 3 hours.

Refer to status code 4+1.

Loading...

Loading...