ComNav 2001 Autopilot System

P/N 29010017 V1.0 - 22-

With either rudder follower:

The distance between the centerline of the rudder

post and the rudder follower must not exceed 24

inches. Make sure that the ball joints on the

rudder arm and rudder follower arm are facing

upwards as shown in 4. Snap the rod assembly

onto the ball joints. Be sure to close the release

clamps on each socket. Refer to Figure 2, Figure

4 or Figure 5 and adjust the length of the rod to

get the correct geometry with the rudder dead

ahead.

If the locking screw in the rudder follower arm

has been loosened, or the arm removed from the

rudder follower, re-attach the arm and check the

potentiometer centring. When the rudder is dead

ahead, the electrical resistance between the Black

and Green wires and the White and Green wires

should be equal (approx. 600 ohms each).

Be careful to check the installation for any

mechanical obstructions or binding of the linkage,

and correct it now, before it becomes a problem.

The rudder follower is supplied with 50 feet of

cable. Run the cable from the rudder follower

towards the distribution box, ensuring that it is

protected by hose or conduit wherever it passes

through fish or cargo holds, or any other area

where it could be damaged.

If the length of cable supplied is too short to reach

all the way to the distribution box, obtain a

terminal strip and sufficient additional cable from

your dealer. Mount the terminal strip in a

convenient DRY location. Connect the rudder

follower cable to the terminal strip and then the

additional length of cable. Strip the wires, and

attach them to the terminals in the distribution

box as shown in Table 1.

IMPORTANT

If you have installed a hydraulic pump or

drive unit, there are several checks that must

done during the first few weeks of usage in

order to prevent poor or dangerous steering

and autopilot performance

Residual Air

After installing and bleeding your pump, residual

air may be trapped in the hydraulic steering fluid.

This air will gradually bleed through the header

tank or the highest helm pump and the oil level

will go down. Check the oil level several times

during the first few weeks of use and add oil as

required.

Leaking Fittings or Equipment

After installing and bleeding your pump,

continously monitor the oil level of your header

tank or the highest helm pump and add oil as

required. If this condition persists, it may be an

indication of leakage in your steering system.

Check all hydraulic steering parts, fittings and

lines for leakage.

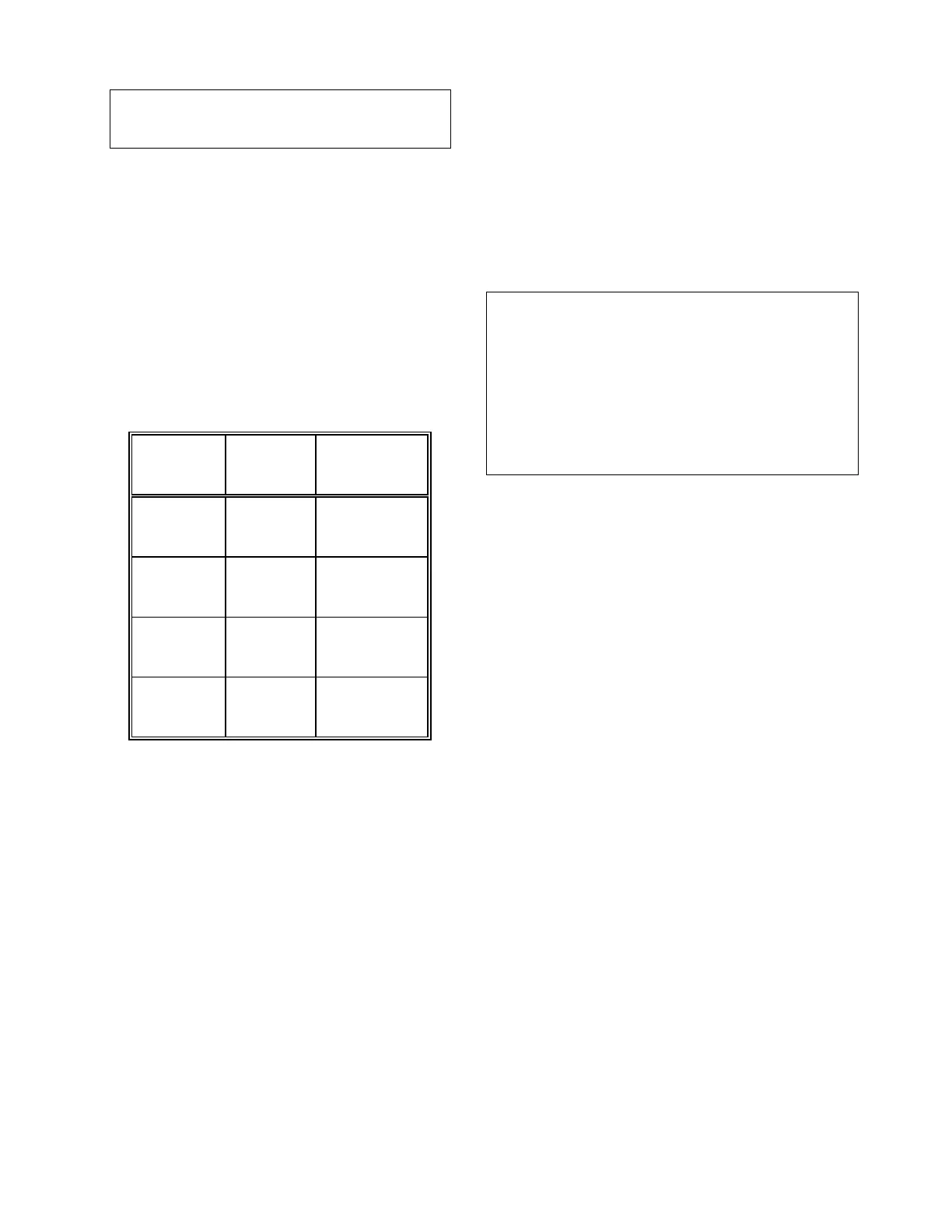

Table I - Rudder Follower Cable Connections

Loading...

Loading...