1.1. Incorrect number or placement of flat springs

The upper half of a bottom crust die set has a series of fasteners, pins, and flat springs

that must be properly configured for successful crust production. Occasionally, the flat

springs and the pins need replacement due to normal wear and tear.

A properly functioning bottom crust die set forms dough to the thickness specified in

the original purchase order. For many of our customers, the specified thickness is 1/8

inch across the bottom, 1/8 inch thick on the sidewall, and 1/8 inch thick on the rim.

If ever in doubt, measure the unbaked dough crust thickness with a small ruler.

Typically, Dies Sets will have locations with two or three flat springs. When there are

only 2 flat springs, they should be stacked vertically and positioned so that they reach

across the ring of the die. Where there are 3 springs, the bottom two springs should be

stacked vertically and extend onto the die’s ring. ONLY the top-most spring should

extend over the stripper pin.

In either case, the springs should always be attached to the die so that the bend in the

middle of the spring is the highest point on the spring.

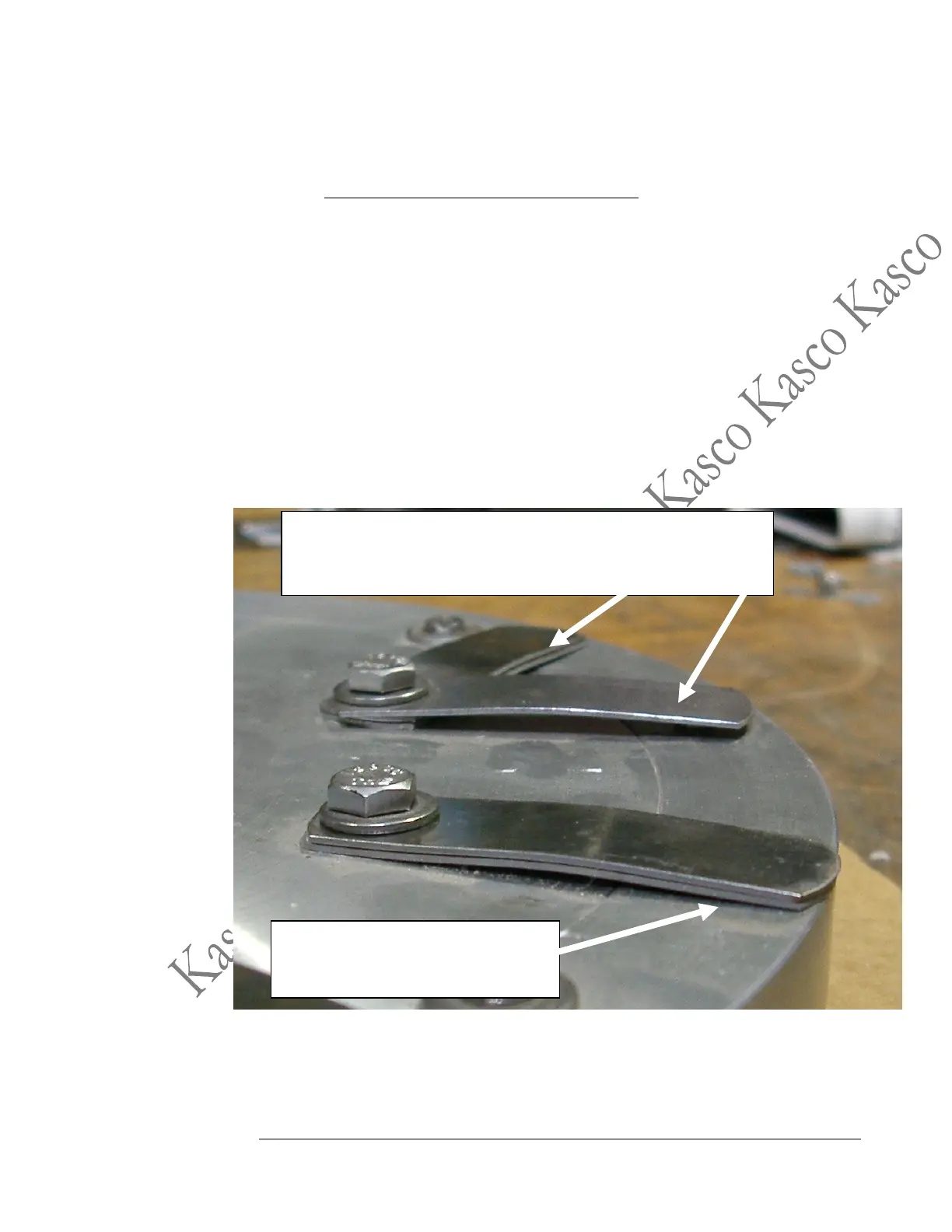

Correct 2-spring location. Springs

are stacked, touching the ring and

reaching out over the ring.

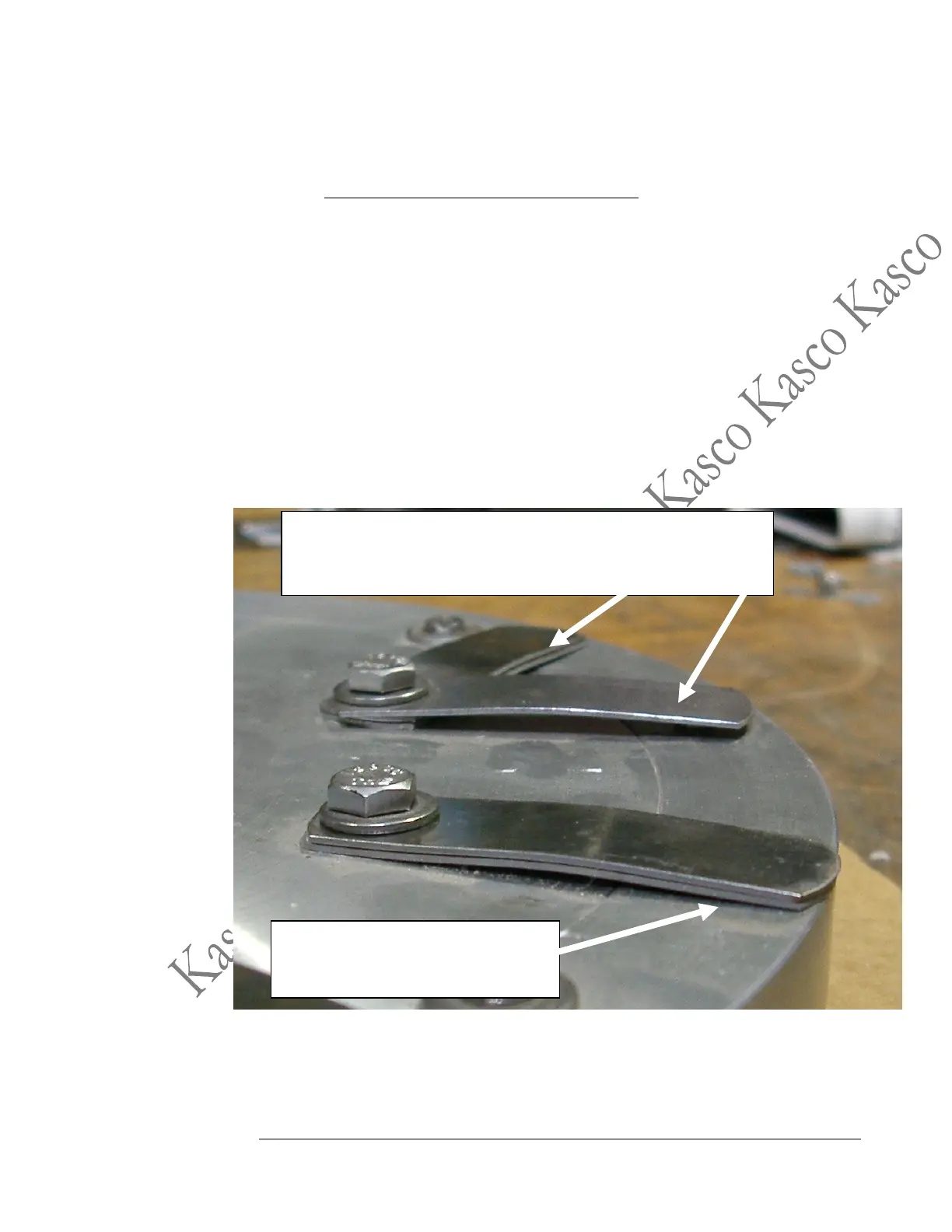

Correct 3-spring location. Lower 2 springs are stacked, touching

the ring and reaching out over the ring. ONLY the upper spring

is covering the pin.

Loading...

Loading...