6 - 3 2 l Tr o u b l e s h oo t in g

C h e c k i n g or Re p l a c i n g Tem p e r a t u r e

S e n s o r s

The Carousel Plus W series dryer uses RTD sensors to monitor the temperatures of the dry-

ing air, the return air, the regeneration outlet, the regeneration inlet process protection and

setback at the outlet of the hopper.

To check or replace RTD sensors:

1 Disconnect and lockout the main power supply.

2 Remove dryer panels, as necessary.

3 Locate the RTD sensors.

4 Check the sensor positions and conditions. Temperature readings will be incorrect, if

the sensors are touching the wall of an air hose or pipe or if the sensor or wiring is dam-

aged. The tip of the sensor should be centered within the air hose or pipe. Sensor wires

should be attached to the appropriate connection points on the dryer’s electrical enclosure

or microprocessor board.

5 To check with ohm meter, measure the resistance across the RTDs. The

resistance should be approx. 110 ohm at room temperature.

6 Replace the sensor, if necessary.

IMPORTANT

: Always refer

to the wiring diagrams

that came with your dryer

to locate specific electri-

cal components.

Illustrations in the User

Guide are intended to be

representative only.

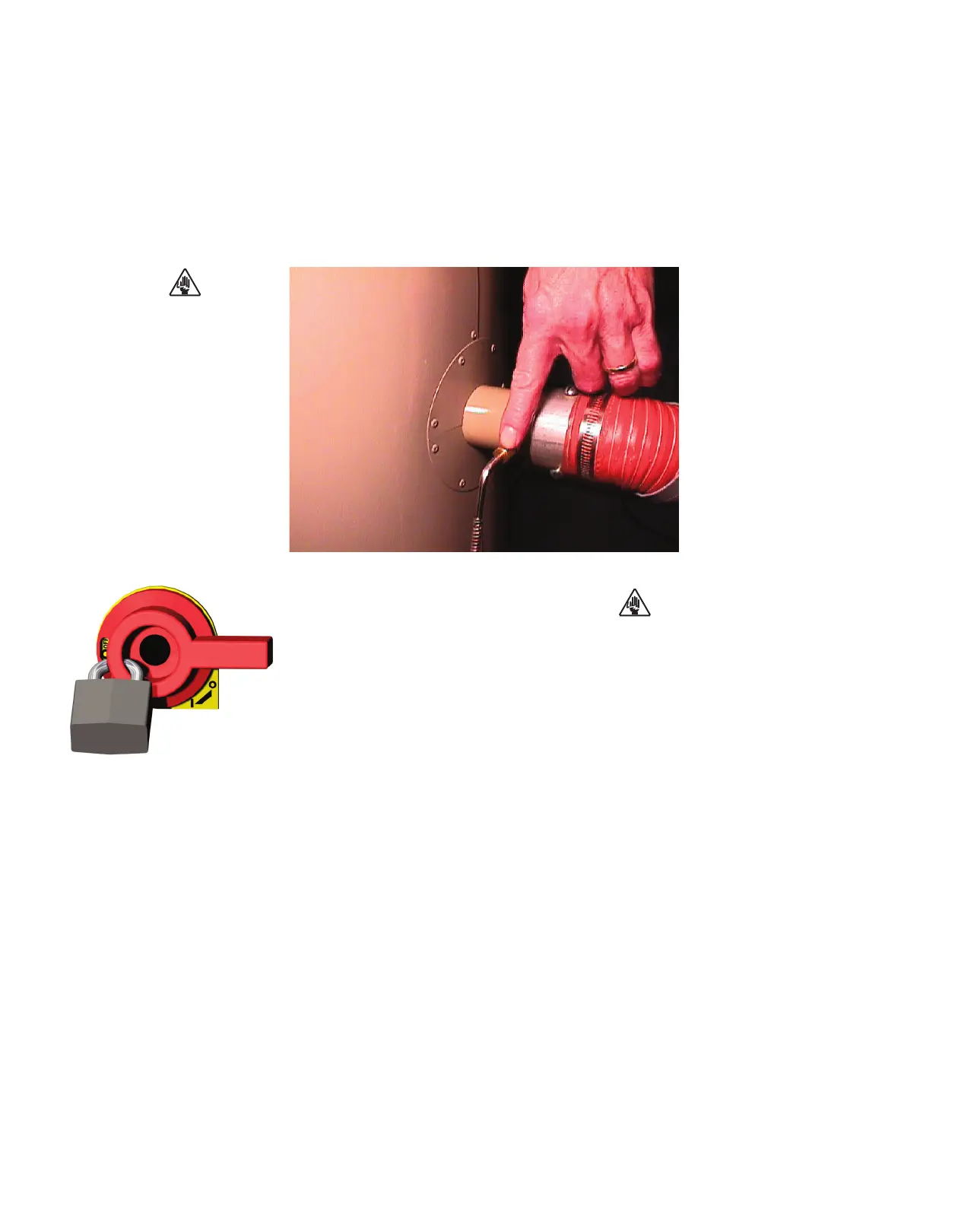

Location of

the Process

RTD at the

Hopper inlet.

Loading...

Loading...