2 - 6 l D es c ri p ti o n

S p e c i f ic a ti o ns : C ar o u s e l P lu s W Se r ie s

D r y er s

MODEL W150 W200 W300 W400

Performance characteristics (with full hopper)

Drying temperature

†

All models 100

°

- 375

°

F {38

°

- 191

°

C} with options

Dew point All models -40

°

F {-40

°

C}

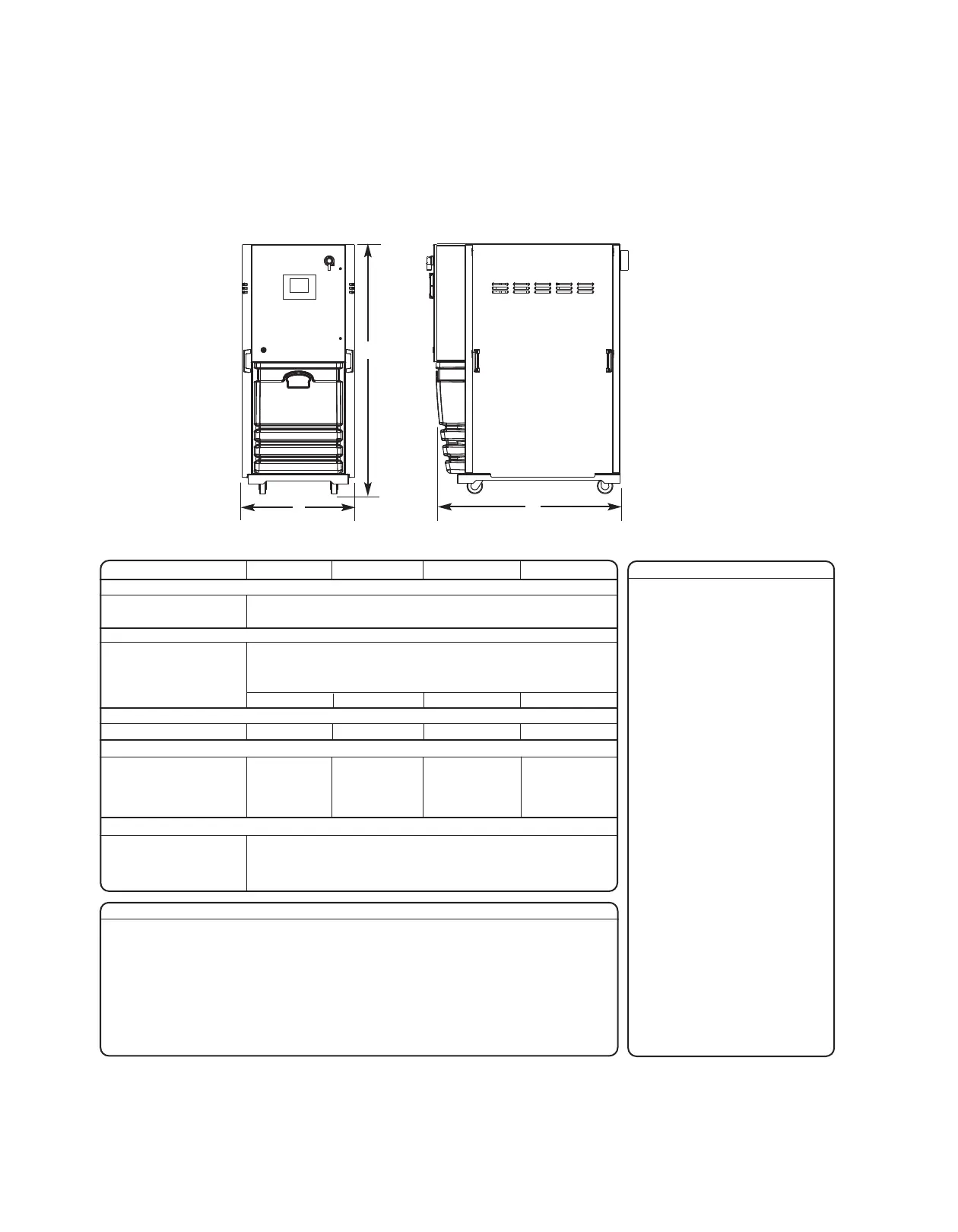

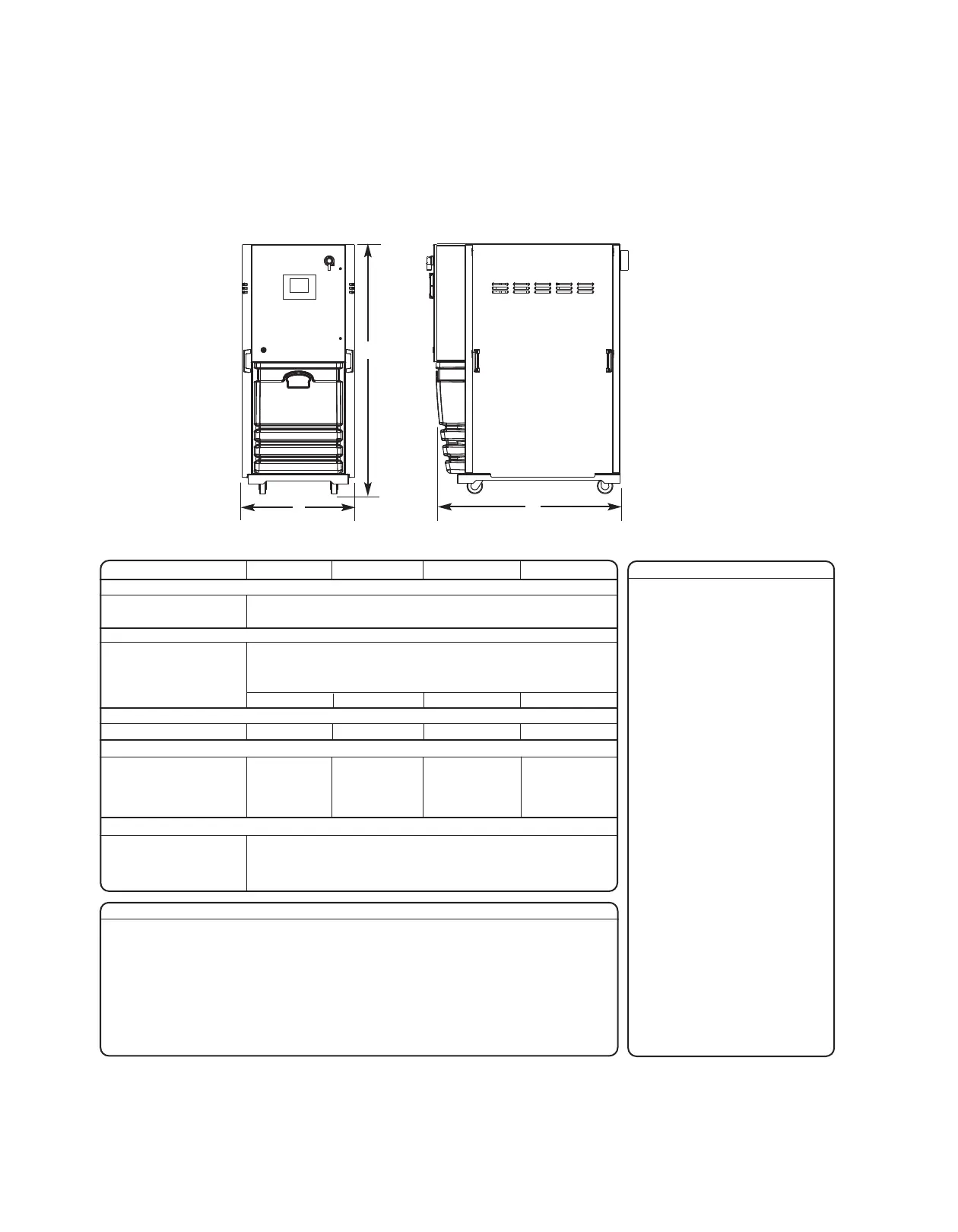

Dimensions inches {cm}

A - Height 64.3 {163.3}

B - Overall width 29 {73.7}

C - Depth 51.5 {130.8}

Outlet/inlet tube size OD 2.5 {63.5} 5.0 {127.0} 5.0 {127.0} 5.0 {127.0}

Weight lbs {kg}

Standard dryer installed 600 {272} 660 {300} 710 {322} 760 {345}

Voltage - Full load amps Standard/Central drying

230 V/3 phase/60 Hz 47.1 / 16.7 57.6 / 19.9 67.7 / 30.0 N/A

400 V/3 phase/50 Hz

*

23.4 / 8.9 32.1 / 10.4 37.9 / 16.2 64.5 / 21.1

460 V/3 phase/60 Hz 21.0 / 8.4 28.9 / 10.0 34.0 / 15.1 56.3 / 18.6

575 V/3 phase/60 Hz 16.8 / 6.7 23.7 / 8.6 27.3 / 12.2 43.2 / 13.0

Water requirements {for aftercooler or optional precooler}

†

Recommended temperature

‡

45

°

- 85

°

F

Water flow

gal./min. {liters/min.}

3 {11.4}

Water connections NPT 3/4 inch NPT

SPECIFICATION NOTES:

* Dryers running at 50 Hz will have 17% less airflow, and a 17% reduction in material throughput.

†

When drying below 150°F {66°C} a precooler is required.

‡

Temperatures above or below the recommended levels may affect dryer performance.

Tower, chiller or municipal water sources can be used.

Specifications may change without notice. Consult a Conair representative for the most current information.

C

B

A

APPLICATION NOTES:

All dryers are supplied with an aftercooler

as standard. The aftercooler reduces the

temperature of the return air from the dry-

ing hopper, improving the efficiency of the

desiccant. The aftercooler must be connect-

ed with the proper water flow rate and tem-

perature to attain the rated throughput.

When to use central models

Central dryers do not have process

heaters. These models should be used

when drying multiple materials that

require different drying temperatures.

Central models dehumidify the process

air, which is then heated to the correct

setpoint by a Heater Pack mounted on the

hopper and controlled from the dryer.

When to use additional filtration

The standard return air cartridge filter is

sized for the airflow of each dryer model

and is suited for most applications. You

should consider adding an optional dust

collector and/or volatile trap if:

●

The material contains excessive fines. An

additional dust collector or cyclone will

extend time between filter cleaning.

●

The material produces volatiles during

drying which condense into a waxy or

oily residue. A volatile trap will help to

protect the desiccant.

TPDX018-0113

Loading...

Loading...