Service Handbook OEB/OES/OGB/OGS

Safety:

When working on the operation module, make sure that the main power

supply is disconnected (an all-pole isolation switch with a minimum contact

opening of 3mm must be located close to the unit- on site) and ensured

against switching on again.

This work should only be performed by a CONVOTHERM trained electrician.

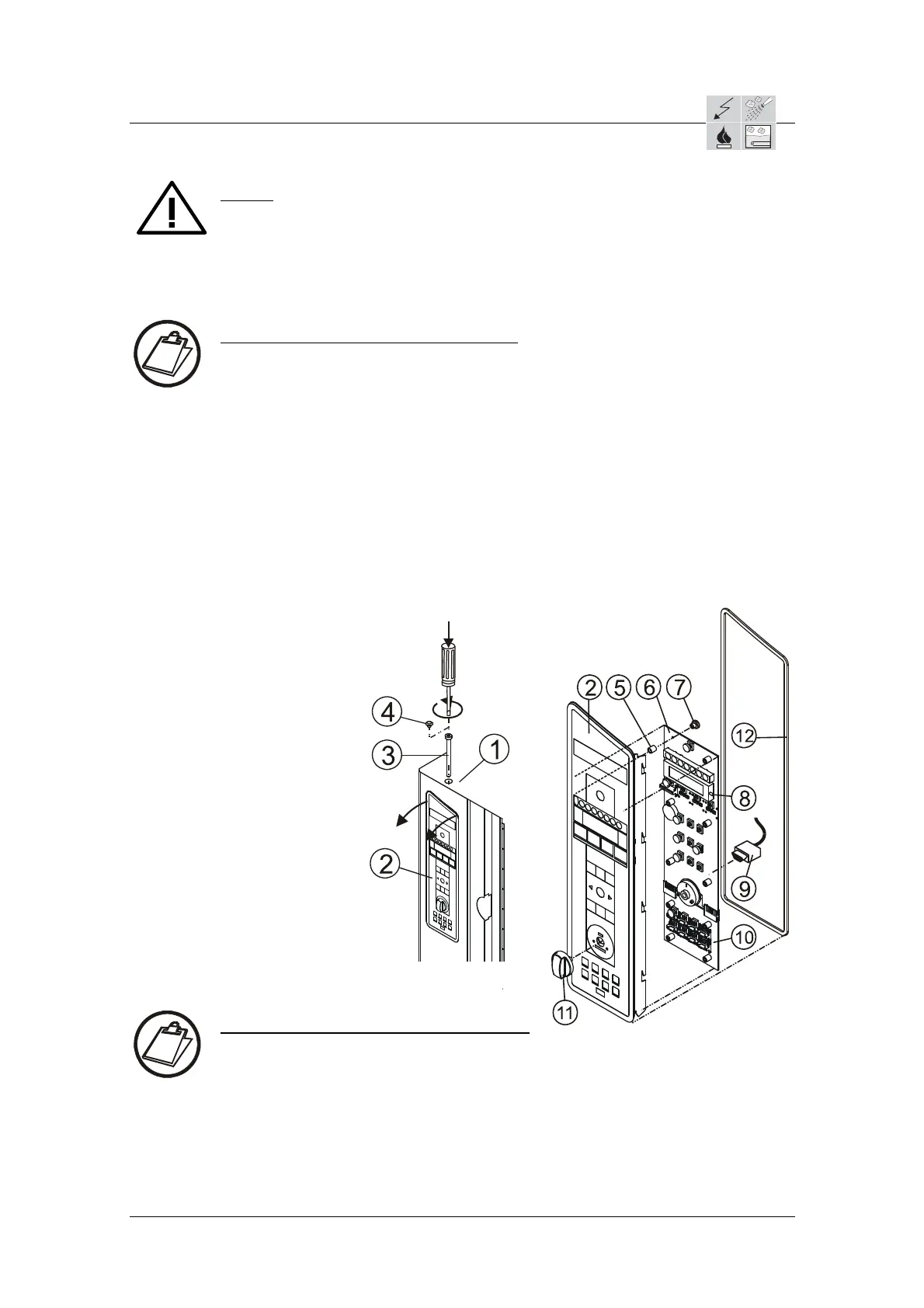

Instructions: Operation module removal

Remove the cap 4 from the hexagon locking screw 3 on the unit top 1.

Turn the hexagon locking screw 3 counterclockwise approx. 12 times.

To release the front plate 2 press the hexagon locking screw 3 as far down as

it will go. By lightly tapping the front part, the front plate 2 will clap out forward.

Lift the front plate 2 downwards out of the holder and lay it next to the unit.

(cable length 1,8m).

Loosen and unplug the 9 pole connector 9 on the back side of the operation

module 6.

Unscrew the 6 knurled nuts 7 and pull out the operation module 6 straight and

evenly from the fastening.

Attention: Don‘t lose distancing bushes 5 and the light guide around the keys

and don‘t damage vacuum cylinders 8 on the side of the display Display

defect!

SW5

8 = Unit top

9 = Front plate

10 = Loc

king screw with

hexagon socket

11 = Cap

12 = Distancing bushes

13 = Operation module (BM)

14 = Knurled nuts

15 = Vacuum cylinders

16 = 9 pole connector to

Control module

17 = Picto module (PM)

18 = Adjustable knob

19 = Sealing frame part no. 7011010

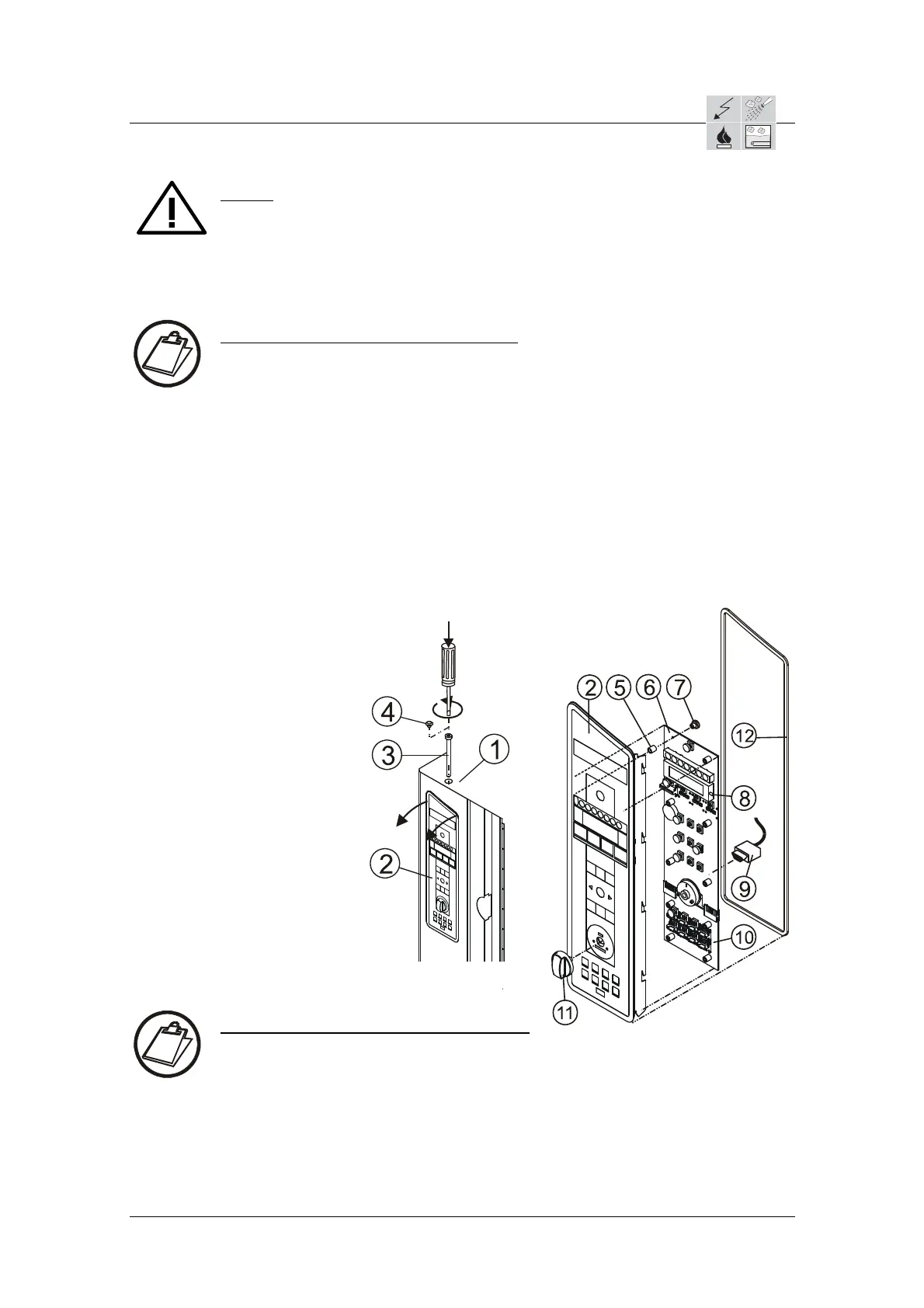

Instructions: Operation module assembly

Place operation module 6 straight and evenly onto the fastening bolts.

Attention: Make sure that the distancing bushes are present 5 and push the

light conductor straight and evenly onto the loop element.

Screw on the 6 knurled bushes 7 and tighten.

Plug in the 9 pole connector 9 on the back side of the operation module 6 and

tighten.

Check the sealing frame part no. 7011010 and replace if damaged.

AS/11-2011 6_01e_Electronic Control Board installation_c

Page 2 / 8

Loading...

Loading...