INSTALLATION, OPERATION AND MAINTENANCE MANUAL – COSA 9610™

30 | Page

adjusted based on the application.

After this throttle back the output of the analyzer flow to 40 liter/hr (660 CCM or 1.4

CFH) using the needle valve on flow meter tagged "Analyzer flow".

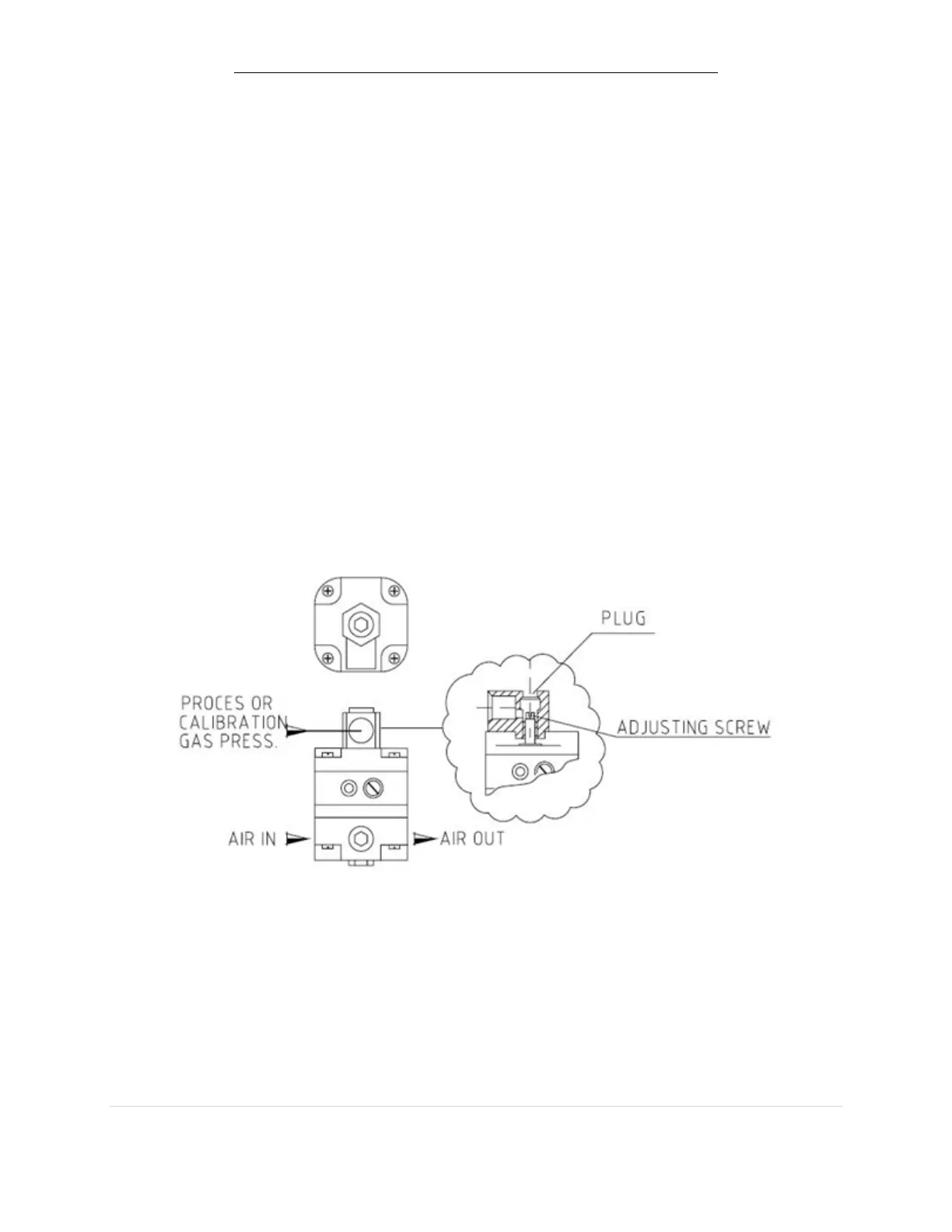

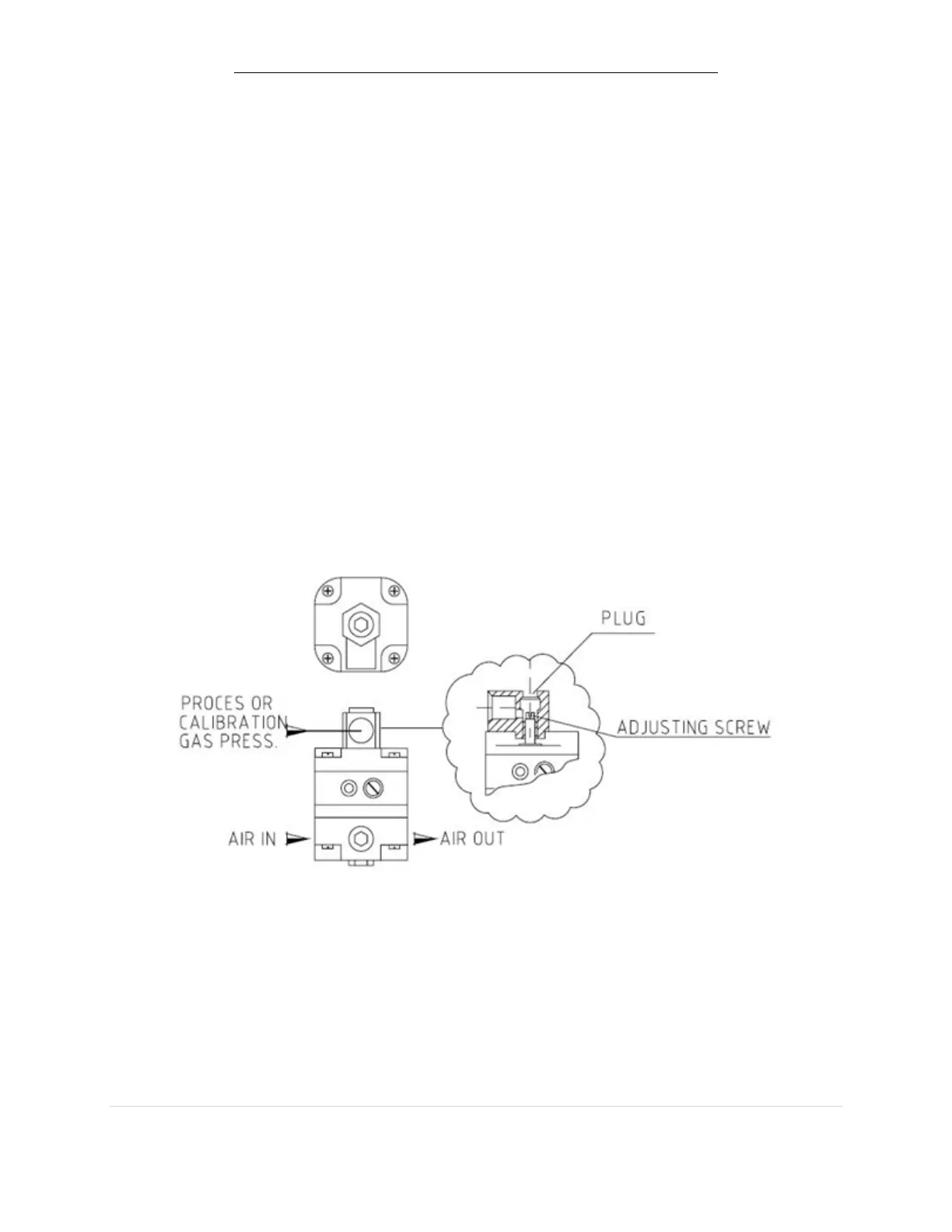

3.1.6. Adjusting booster relays

Set the chosen residual O

2

set point with help of the booster relay. With the

booster relay it is possible to give a small negative (i.e., the gas pressure is higher

than the air pressure) or positive offset of max 0.5 bar, as set point correction or as

pressure drop compensation over the air- and gas tubes in the heat exchanger.

To change the offset pressure, remove a plug on the top the top of the booster

relay. Using a screwdriver slowly turn CCW until a decent negative offset is reached.

In other words, the air pressure is lowered in comparison with the gas

pressure. The correct choice of a negative rather than a positive offset needs to be

used for proper analyzer operation. The chosen residual oxygen concentration,

combined with the average of the chosen range of measurement, gives according to

these curves the selection of the air nozzle and an indication for the booster offset.

!

Caution

The adjusting screw is located in the gas compartment of the relay. When the plug

is released, gas will escape. Be prepared before the relay is going to be adjusted,

e.g., have the right equipment readily available, so the gas compartment must be

open for only a minimum of time.

Loading...

Loading...