INSTALLATION, OPERATION AND MAINTENANCE MANUAL – COSA

9610™

8 | Page

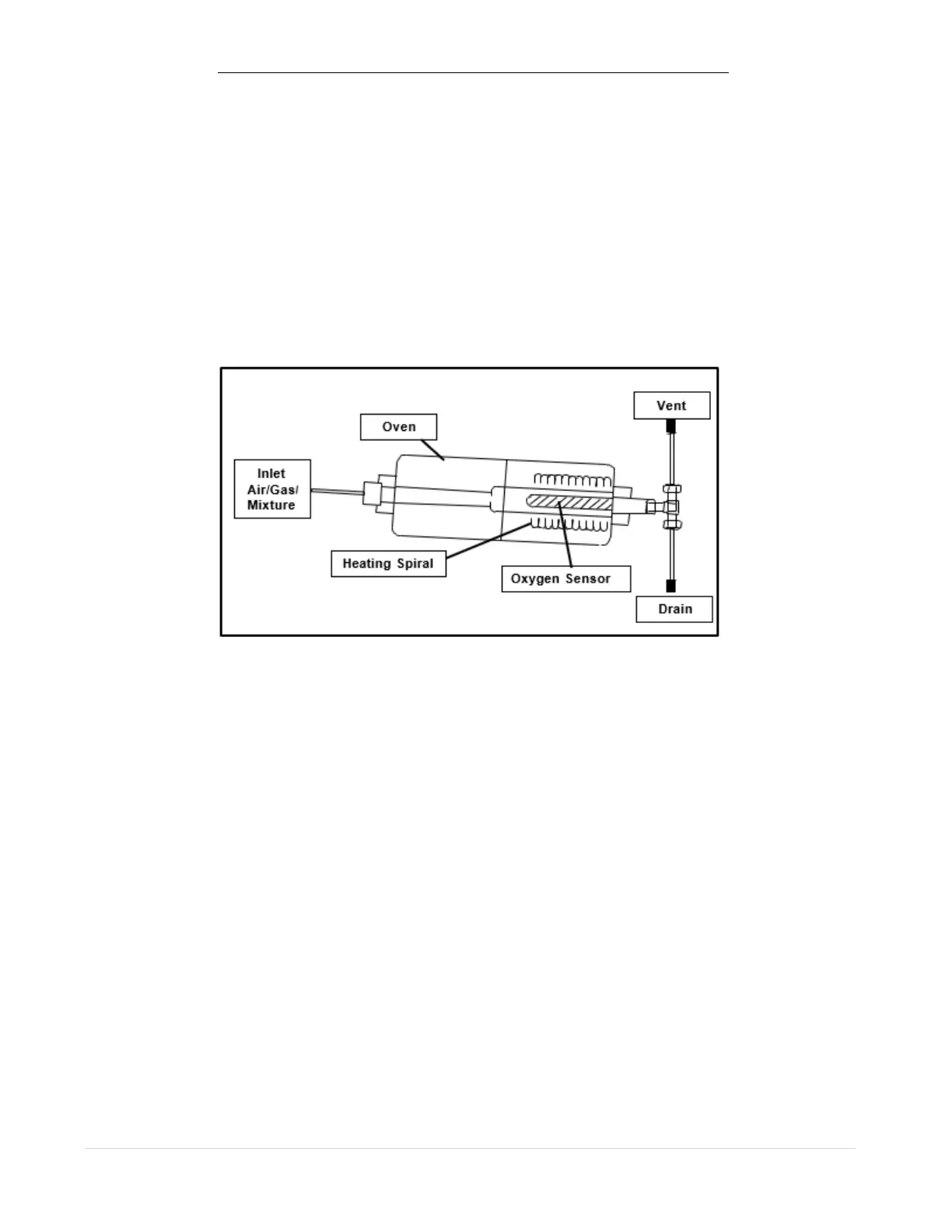

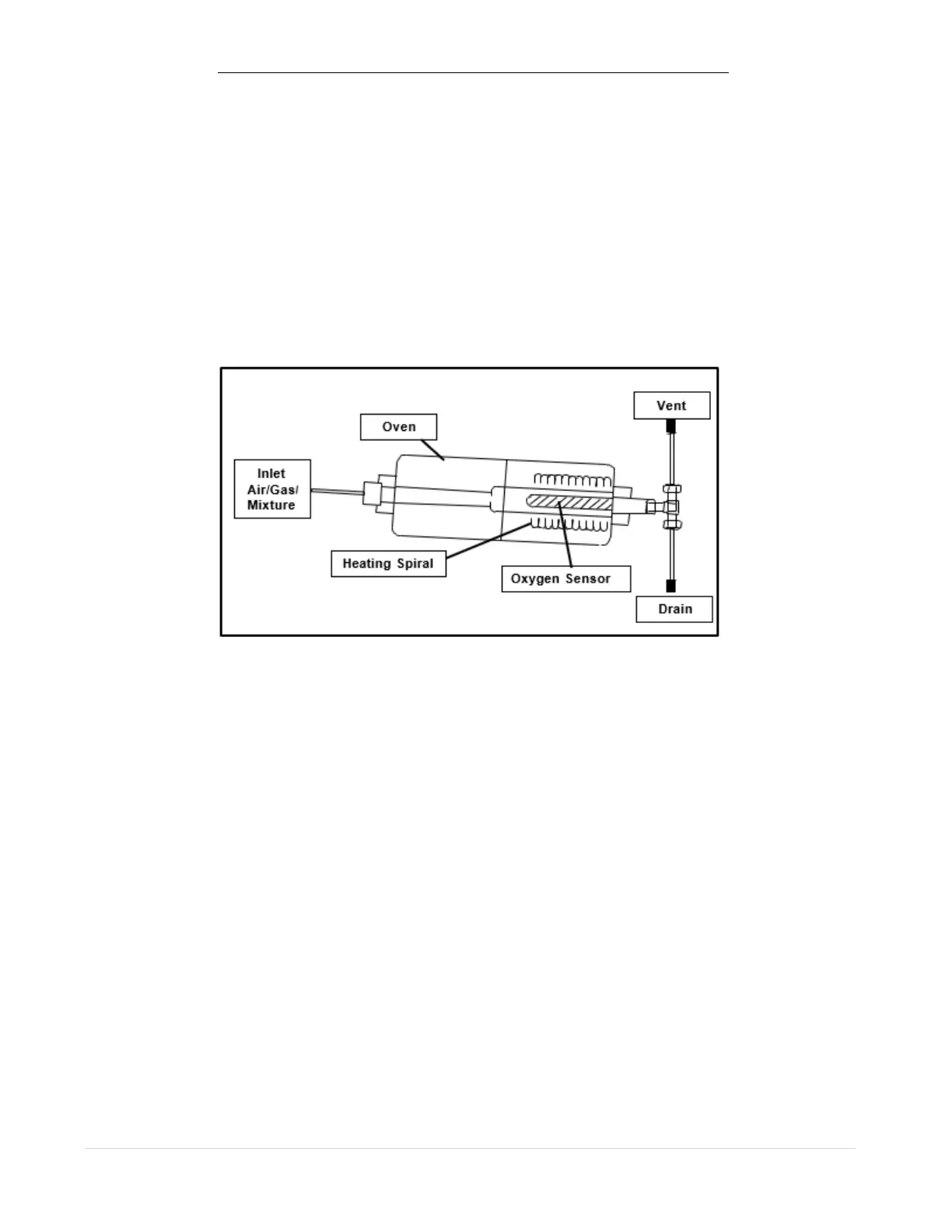

1.2.1. Oven with oxygen sensor

The gas/air mixture is burnt catalytically in an oven, which is kept at 812ºC with a heating

spiral. The temperature is maintained with temperature control using a K-type

thermocouple. The oxygen sensor in the oven is a zirconium oxide cell. This is mounted

such, that one side is in contact with the outside air and the other side with the flue

gasses. At high temperatures, (600ºC) O

2

-ions in the ZrO

2

grating become mobile through

vacancies therein. By fixing porous Pt-electrodes at both sides of the ZrO

2

, O

2,

gas

molecules can, through diffusion by and uptake of two electrons from the Pt electrode,

enter the ZrO

2

as O

2

-ion, move to the other electrodes, and be converted in gaseous O

2

again by release of the two electrons.

1.2.2. The sample system (SCS)

In the sample conditioning system (SCS), gas and air are mixed in a constant proportion,

such that a small excess of air is present (± 2.5% oxygen) in the flue gas. The gas and air

pressure are equalized by a dome-loaded pressure reducer (or booster relay), where the

gas pressure governs the air pressure.

The booster relay has a temperature reducing effect; the gas/air mixing proportion can

therefore vary as consequence of variations in viscosity. Therefore, the temperature of the

gas and the air are equalized in a heat exchanger. The gas and air temperature are still at

surrounding temperatures, however, as long as gas and air fluctuate to the same extent

this hardly influences the mixing proportion. In case of large surrounding temperature

fluctuations, the calibration sequence has to be performed more often. Hereafter gas and

air are mixed in the mixing chamber. The mixing chamber is equipped with orifices in the

inlet nozzles. The gas and airflow are determined by a critical expansion over the orifices.

The turbulence created provides a homogeneous mixture.

The diameter ratio of the orifices, together with the ratio between gas and air pressure,

determine the mixing proportion.

Loading...

Loading...