INSTALLATION, OPERATION AND MAINTENANCE MANUAL – COSA 9610™

46 | Page

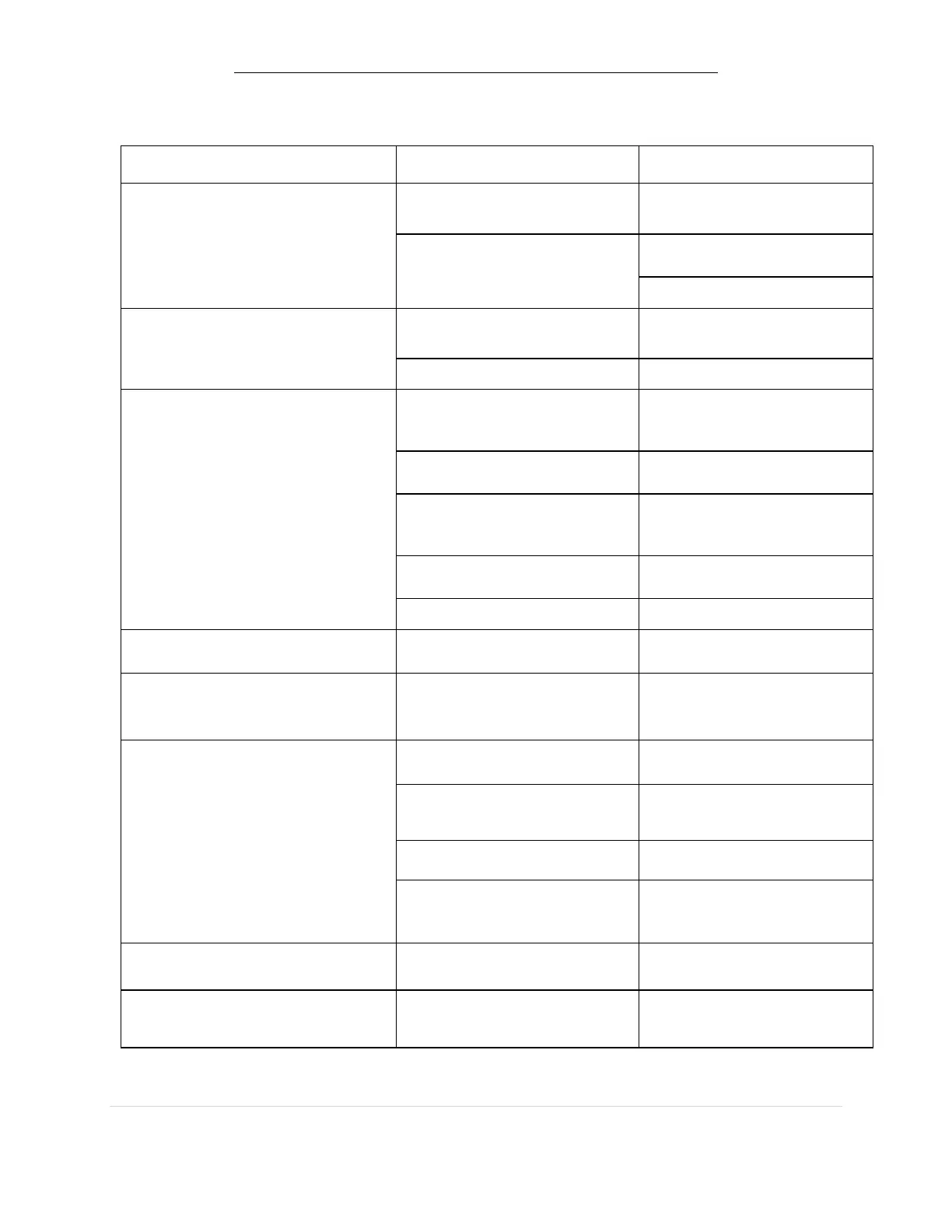

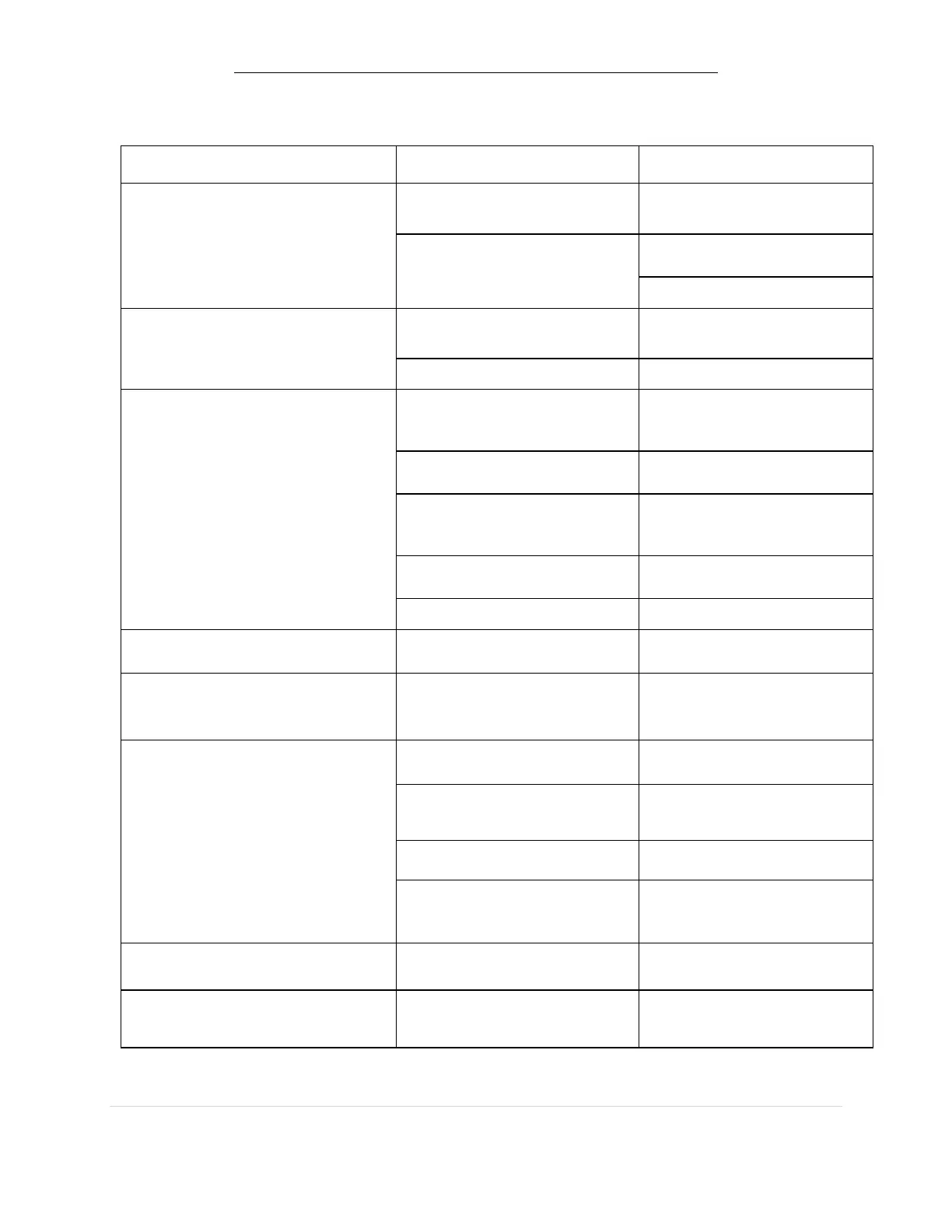

4.3. TROUBLESHOOTING

Breakdown -> fault report

Test

Action

No air pressure

->

flow

alarm

For Z-purge

tube

fracture, leak in the system

Check for leak

Replace

tube

Measuring pressure

behind

reducing

valve (for z-purge)

Open valve for reducing valve

No gas pressure -> flow

alarm

Tube

fracture

Close main valve

immediately

and replace

pipe

Check/clean/replace

tubing

Oven temperature below 750°C

->

temp low

alarm

Controller. Check fuse 1 in

TB1

of regulated

supply

Reset

Check fuse 4 in TB4 of

temp.

controller (display is

off)

Replace

Check output voltage

temp.

controller (0-5 VDC) to

Solid

State

Contact

supplier

Check pulsating voltage

(0-60

VAC) to

oven

Contact

supplier

Check oven resistance ± 13 Ω

Contact

supplier

Analyzer becomes slow > 20

seconds

Check system flows and

gas

pressures

Clean system and/or adjust

to

correct

values

Check resistance of cell,

when

sample gas is “shut off” it

should

be lower than 1000 Ω

No response from

analyzer

Response to mV signal on

cell

input

terminals

Electronic problem.

Check

interface board or

computer

Response to mV signal on

cell

input

terminals

Clean systems and/or adjust

to

correct

values

Check or the test value is set

to

“NO”

Simulate mA signal

wiring.

Check test value on 0%,

25%,

Contact

supplier

Loading...

Loading...