INSTALLATION, OPERATION AND MAINTENANCE MANUAL – COSA

9610™

9 | Page

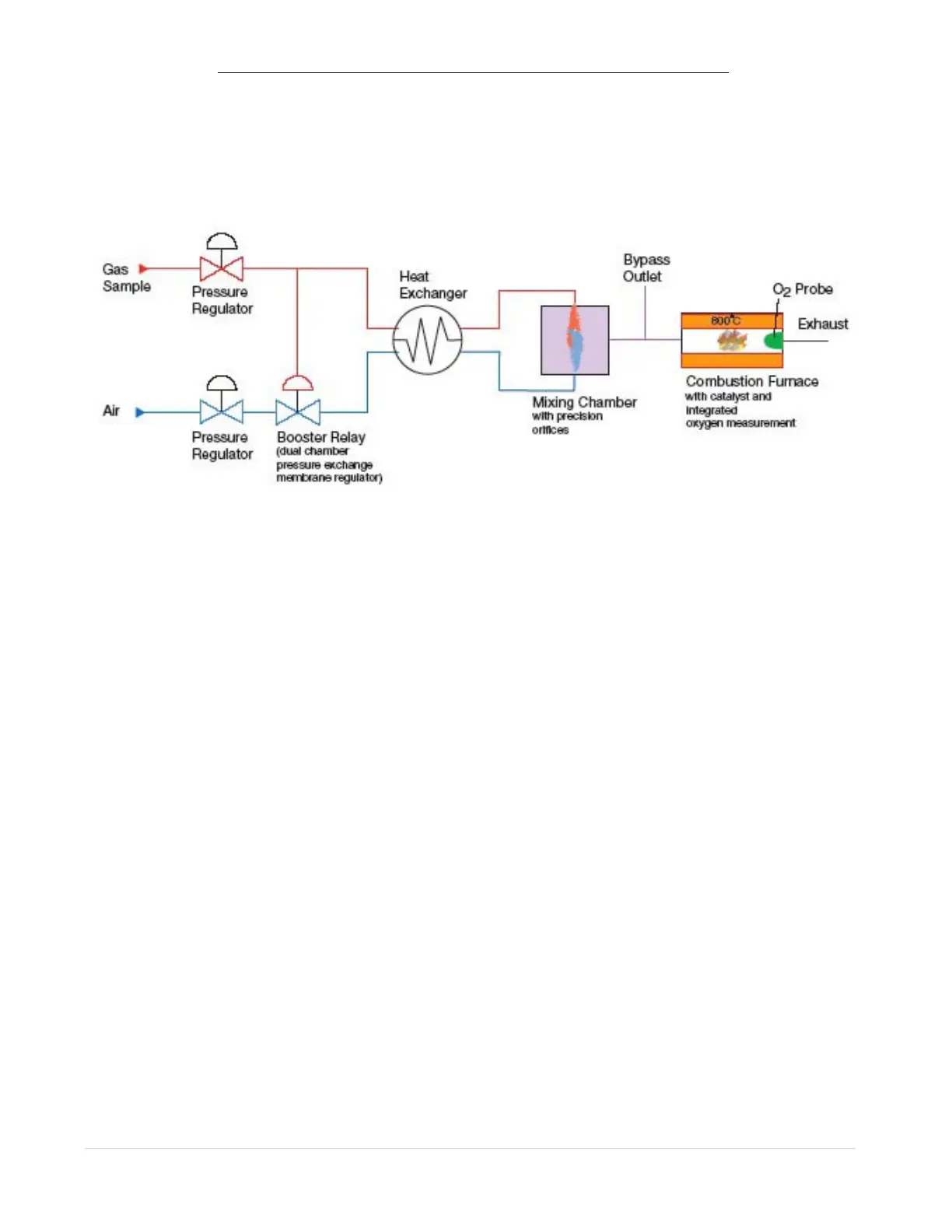

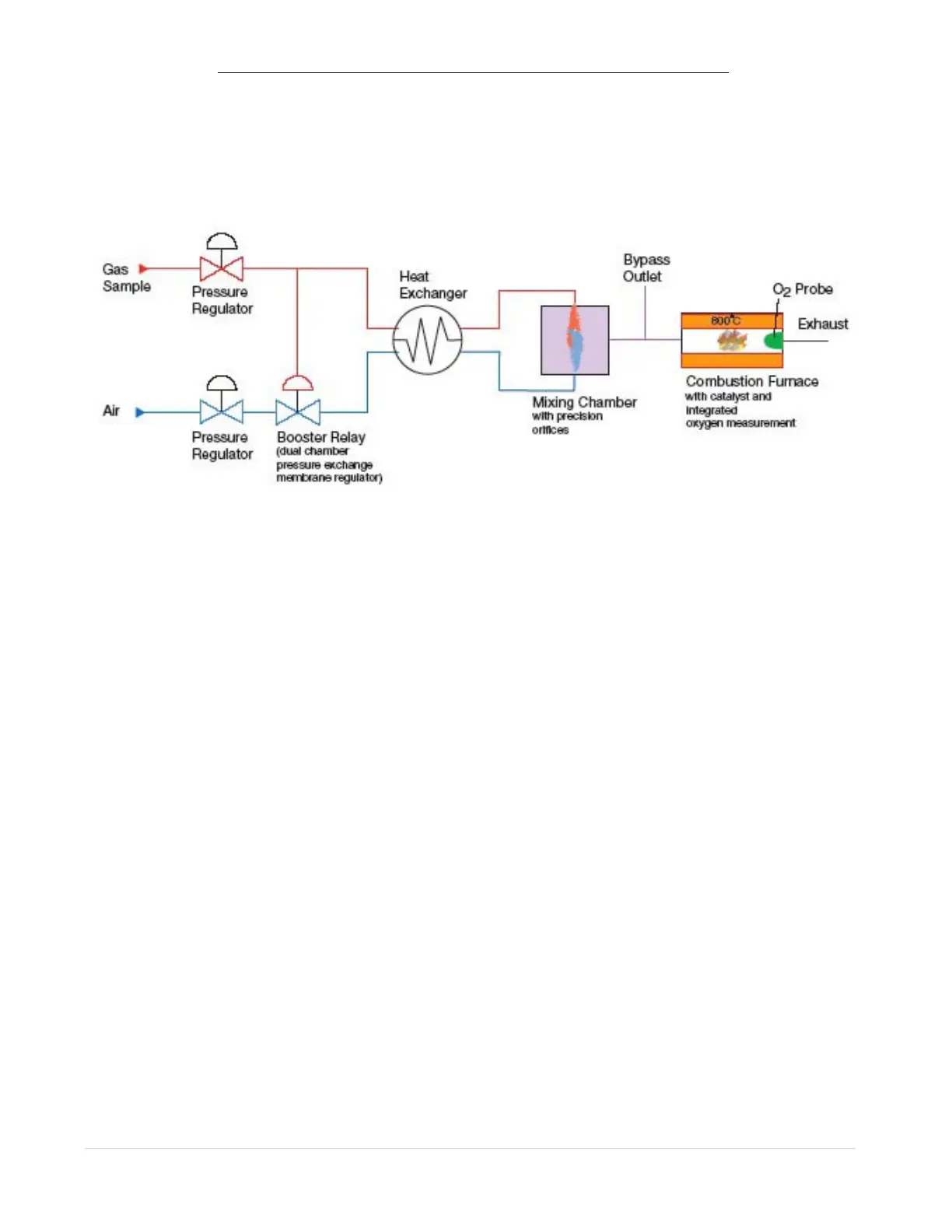

After the mixing chamber, the mixture flow is divided into an excess flow to vent and a

flow to oven. The flow to the burning oven will be approximately 30-50 Nl/hr (500 - 800

Ncc/min). The vented stream is approximately 500 Nl/hr (8000 Ncc/min) with a maximum

1000 Nl/hr (16,000 Ncc/min).

1.3. CALIBRATION PROCEDURE

The analyzer can be calibrated in three different ways:

•

Single point calibration

Only one calibration gas is used. The value of the gas is chosen middle of the

measuring range. This is only used to correct any offset error to the measurements.

•

Two-point calibration

Two calibration gases are used. The low calibration gas is set at ± 20% of the

measuring range. The high calibration gas is set at ± 80% of the measuring range.

The advantage over a single point calibration is the increased accuracy over the entire

span.

•

Three-point calibration

This method uses three calibration gases and is mandatory for a dual range analyzer.

The medium range calibration gas must be in the middle of the measuring range.

All three calibration methods can be performed both manually and automatically:

•

Manually

The operator navigates the procedure via on-screen menu to open the correct gas

valves to the analyzer. The operator controls the timing.

•

Automatically

Loading...

Loading...