PILOT ADJUSTMENT

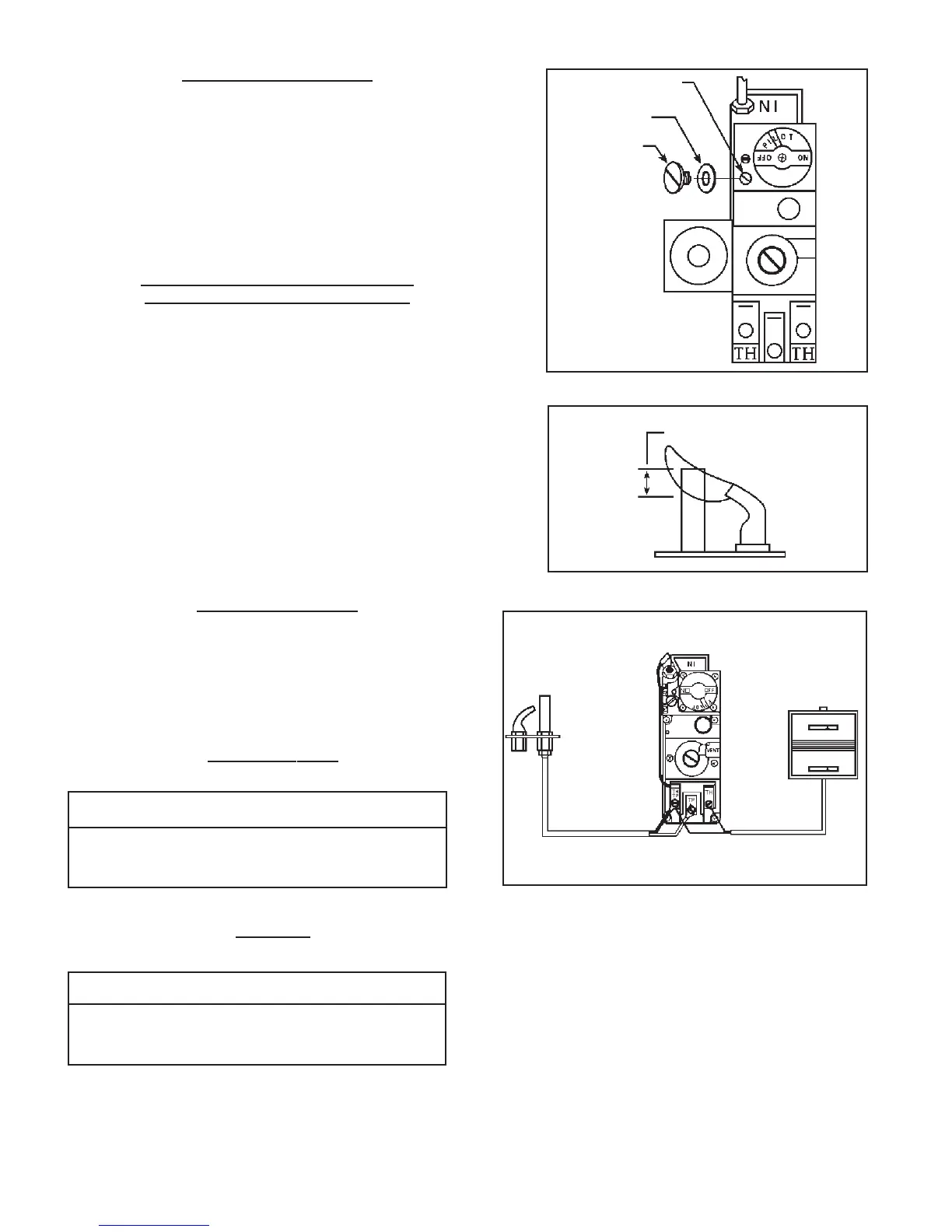

Locate pilot adjustment cap on valve and remove. See Figure 8.

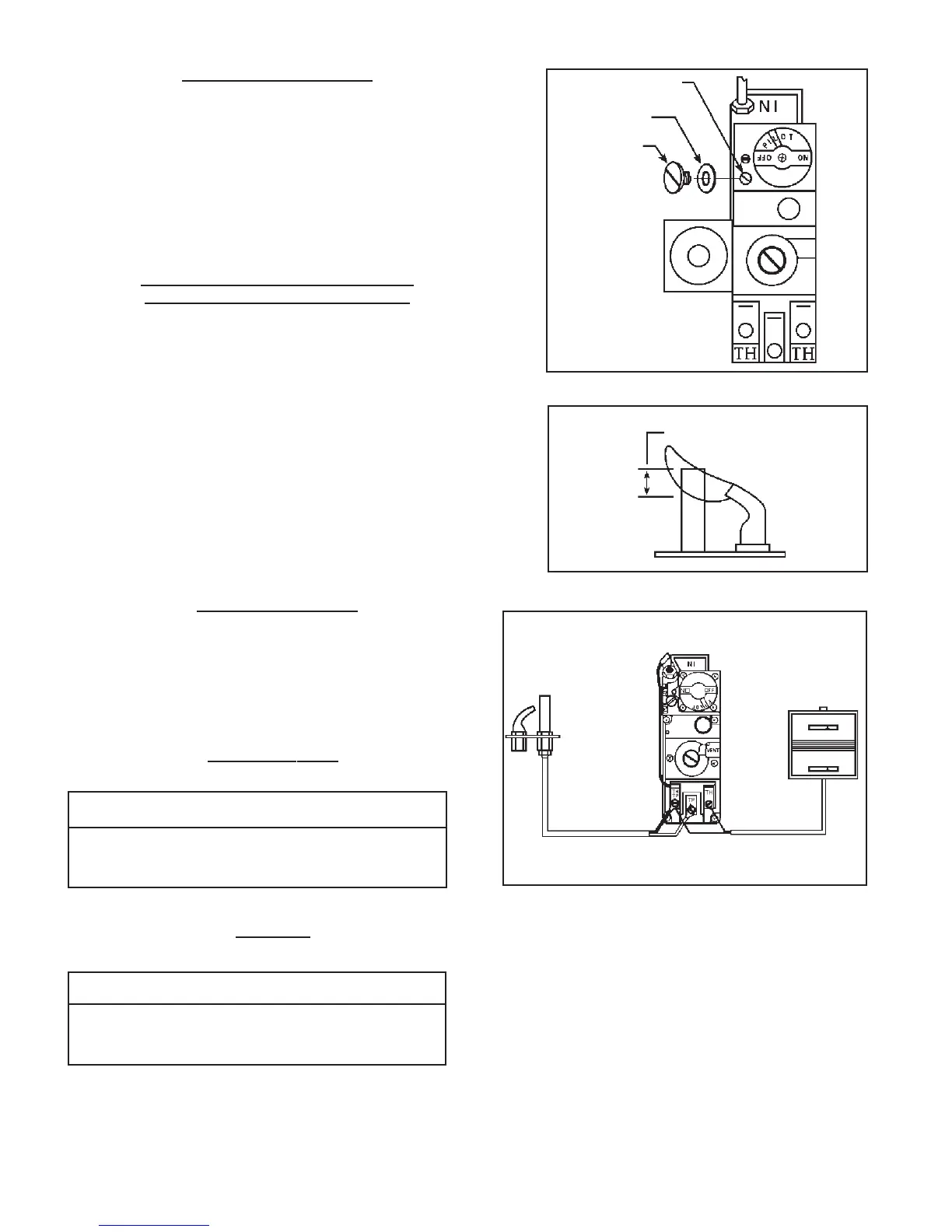

Pilot flame should surround the top 3/8 to ½ inch of powerpile or

thermocouple, see Figure 9. To increase pilot flame, turn pilot

adjustment screw, see Figure 8, counterclockwise. To decrease pilot

flame, turn screw clockwise. After a proper pilot flame is established

replace pilot adjustment cap, be sure gasket located on bottom of

cap head is in place. The gas supply to the pilot is unregulated.

When line pressure exceeds 7” w.c. Natural Gas, 11” w.c. L.P. Gas,

pilot adjustment must be made.

TO REMOVE MAIN BURNER FOR

INSPECTION AND CLEANING

1. Remove outer casing.

2. Disconnect gas supply to valve.

3. Remove 11 screws holding burner door to heat exchanger and

lift out complete burner, valve assembly.

4. After inspecting burner, place back into heat exchanger. Be

sure door gasket is not damaged and will effect a proper seal or

pilot outage will occur.

5. Tighten screws holding burner door to heat exchanger.

6. Connect gas supply back to valve.

7. Install front panel and follow lighting instructions.

NOTE: The furnace and all components must be inspected at least

annually by a qualified service technician. This should include

the burner, heat exchanger, and vent system. Be sure that the

flow of combustion and ventilation air are not obstructed.

BURNER ORIFICE

This appliance is orificed at the factory for elevations up to 2,000 ft.

If installed above 2,000 ft., the BTU input must be reduced 4% per

1,000 ft. See the following orifice chart for the proper orifice for a

specific elevation. Orifice change must be completed by a qualified

installer or service technician.

Pilot Adj. Screw

Gasket

Pilot Adj. Cap

FIGURE 8

WIRING DIAGRAM

Pilot Generator

Leads

Thermostat

Wire

WIRING DIAGRAM

CAUTION: Label all wires prior to disconnec-

tion when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify

proper operation after servicing.

Page 10

FIGURE 9

Pilot flame should envelop

3/8” - 1/2” of powerpile

or thermocouple

NATURAL GAS

SPECIFIC ELEVATIONS

MODEL 0 TO 2,000’ 4,000’ 6,000’ 8,000’

NUMBER 2,000’ 4,000’ 6,000’ 8,000’ 10,00’

CDV155B 48 49 50 51 52

CDV255B 2.45mm 41 42 43 44

CDV335B 2.75mm 37 38 40 42

ORDER KIT #49800 44-1 HIGH ALTITUDE KIT

L.P. GAS

SPECIFIC ELEVATIONS

MODEL 0 TO 2,000’ 4,000’ 6,000’ 8,000’

NUMBER 2,000’ 4,000’ 6,000’ 8,000’ 10,00’

CDV156B 1.2mm 56 57 59 60

CDV256B 1.55mm 54 54 55 55

CDV336B 1.65mm 51 52 52 53

ORDER KIT #49800 44-1 HIGH ALTITUDE KIT

Loading...

Loading...