ADJUSTING TILT GAGE -- Using

an accurate square, set saw blade at _-L_

right angles tO table top. Then adjust

the pointer on the tilt gage (C, fig. 2)

to 0.

ADJUSTI OMITER SCALE

Using an accurate square, block the _ i_

check this cut with the square. If cut

is accurate, set the pointer on the miter

gage scale (J, fig. 2)to "90".

ADJUSTING FENCE II_

_Adjust right-hand fence indicator

(part 135, fig. 4) by positioning fence

so that it touches the right side

of the saw blade- then set indi-

qtO_S

cator at . Move fence to left

side of blade and adjust left-hand

indicator in like manner.

ADJUSTING CAM CLAMP

LEVER If clamping action of

lever (G, fig. 2) is too tight or '_!ili lid! -

too loose, it can be adjusted by in-

creasing or decreasing the effec-

tive length of the rip fence clamp rod (part 6409, fig. 4)

This is done by readjusting the clamp rod nut (part

6407, fig. 4) on the end of the clamp rod in back of the

fence. When properly adjusted, the clamping lever

should lock in a horizontal position or slightly lower.

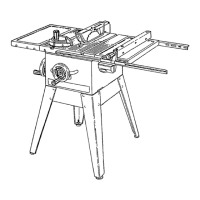

Figure 3

quire no additional lubrication. Other parts requiring

lubrication should be oiled frequently with SAE No. 20

or No. 30 Automobile Engine Oil. See figure 3.

1N Table trunnions m in which cradle tilts.

P Lift screw block, lift screw threads, and lift nut.

Q -- Tilt screw block, tilt screw threads, and tilt nut.

R--Friction points in saw guard.

-T S--Spindle arm pin and saw arbor housing guide

bosses.

T--Saw tilt clamp screw.

AII other points where there is friction between two

or more moving surfaces or where a slip fit is

necessary for adjustment purposes.

Special attention should be given to the moving parts

in the rip fence and miter gage.

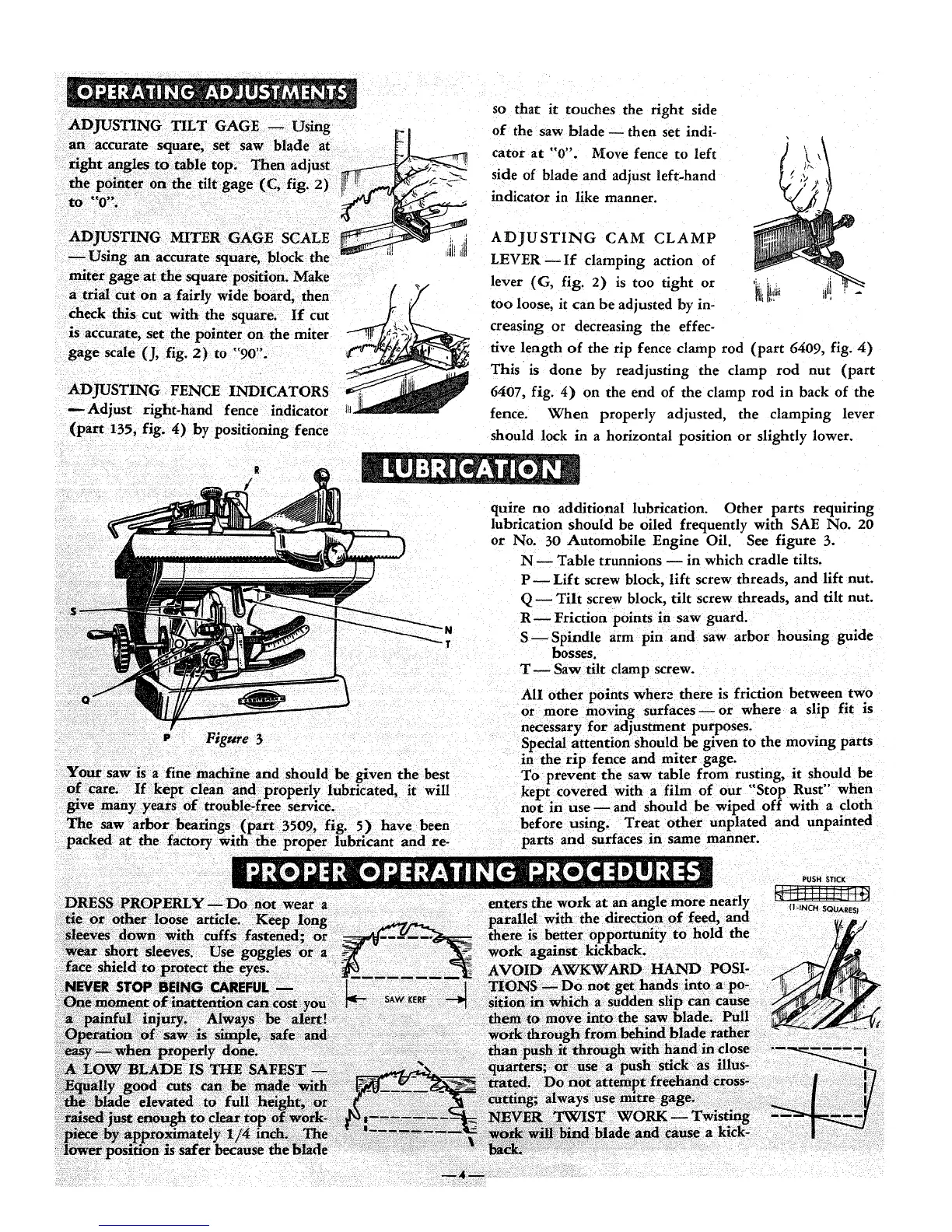

PUSH STICK

enters the work at an angle more nearly

parallel with the direction of feed. ancl .,NO.SOUARES,

there iS better opportunity to hold the

work against kicf_back.

Loading...

Loading...