CROSSCUTTING m Continued

covers table in front of blade, the

gage should be reversed. Square __

cr scuttlngisdonewiththe;niter

gage set at "90" (at a right angle __f,_,_

to the slide and groove). "l-'he _-'_

splitter need not im removed, but

is not needed for this operation.

Start_the cut slowly and hold work _ luIlt_

firmly to table to prevent kick- _ii',iUlltl tlllll_

back or Chatter. (Loosely held

workpieces will sometimes vibrate

against table when crosscutting.

tends to bind blade and dull

teeth.) An auxiliary wooden ex-

tension bolted to miter gage

greatly improves the gage as a

sup oft If fitted with pin points

p •

(phonograph needles are excel- /_fw_

lent) or sandpaper, the extension : //_ €

will help prevent side creep of _/}(I \_

the work. If workpiece overhangs '_ '_----"

table enough to sag at each end, _/_

provide.. supports the same as in

rtppmg operations. The stop rod _/: t\

on the miter gage, or a stop block _/_ _._' :_i

fastened to _e _ension, is used ___, I"

to fix position of left-hand edge __/_/

of work for measuring length of

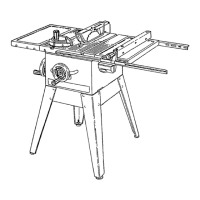

inch wide can be cut. Outside blades can be used alone,

chippers cannot.

A dado insert (part 9-2212, fig. 4) must be used to re-

place the standard table insert. Whenever two or more

chippers are used, stagger the swaged ends as evenly as

possible around the circumference. Fractional adjust-

ments in thickness of the head can be made by using

paper washers between the outside blades and chippers.

Dado head operations are much

the same as those with a standard

blade _ but the dado head takes

a bigger bite, so that workpiece

should be held more firmly. It is

good practice to use a hold-down

jig like the one illustrated.

When a groove wider than the _-

dado head is needed, make two

or more passes. Best method is

to use a notched stop block to po-

sition each successive cut. Block

is fastened to edge of table where

it can be used to position work

before starting the cut; but in such a position that it will

not contact work during the cutting operation. Space

cuts so that they overlap a trifle.

When cutting a gain _ a groove that is closed at one

BEVELAND MITER CUTS end use a stop block to fix the end of the cut. To lo-

cate the stop, place work alongside dado head in position

Bevels from 1° to 45° are cut by tilting the saw blade in wh ...............

Operations are me"same as for ripping'" or crosscutu'ng_" mn It wm De when cut Is nmsneo, then rig the stop

but work should be extra well sup_ortecl to prevent creep, at the end of the work. When

Miters are crosscuts at an angle cutting a stopped groove---which

to the edge of the workpiece. The _ is closed at both ends--also use

miter gage is set at the required a starting block, as shown in the I

angle to make the cut. Here also, •..... _._ ......

•" -- "- ' n - r umstratlon. £111S lS locatea In

precauuons must De rage to p e-

vent same manner as the stop block.

creep. _ .i: _:

USE OF THE DADO HEAD

The dado saw or head, as it is

SANDING

A sanding

mounted

'forfine

Loading...

Loading...