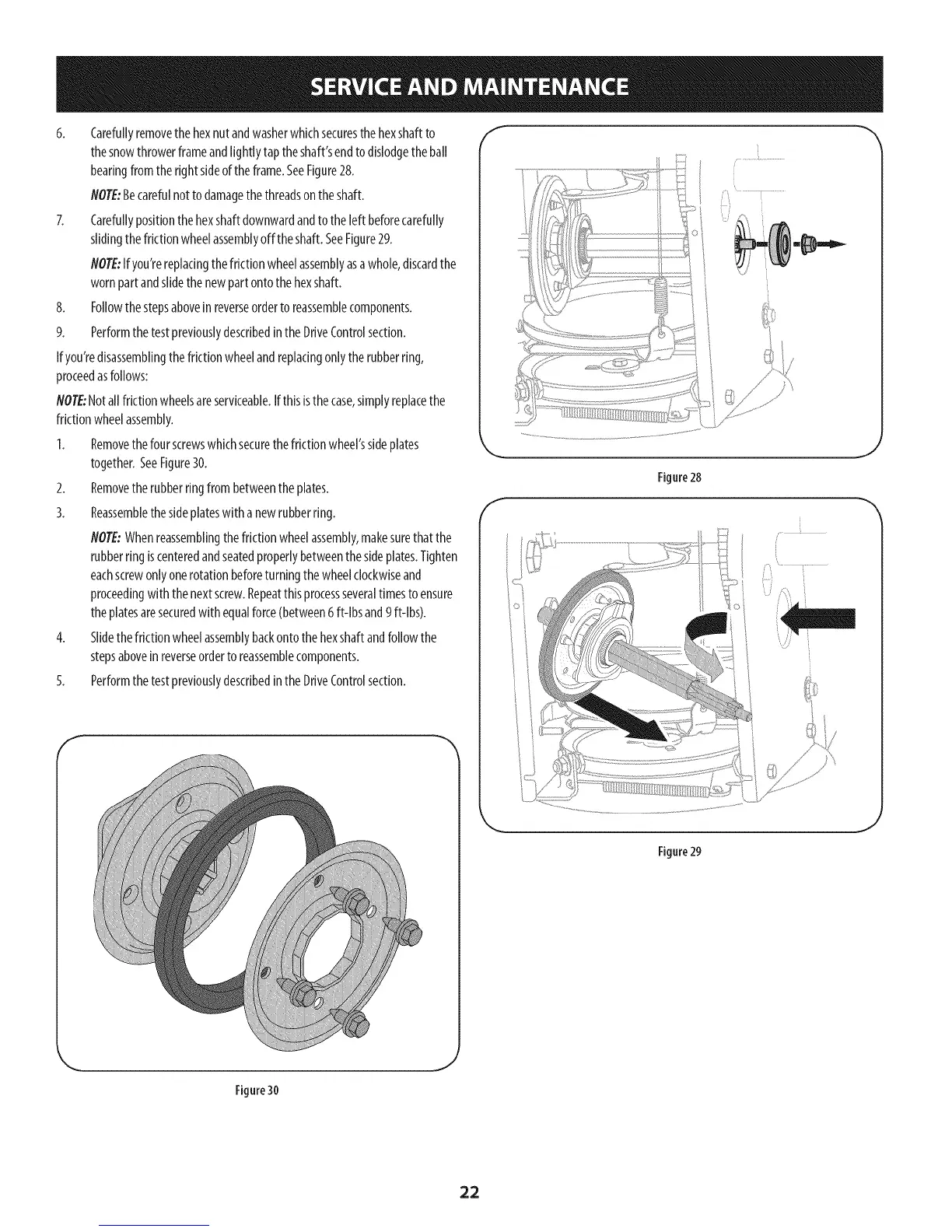

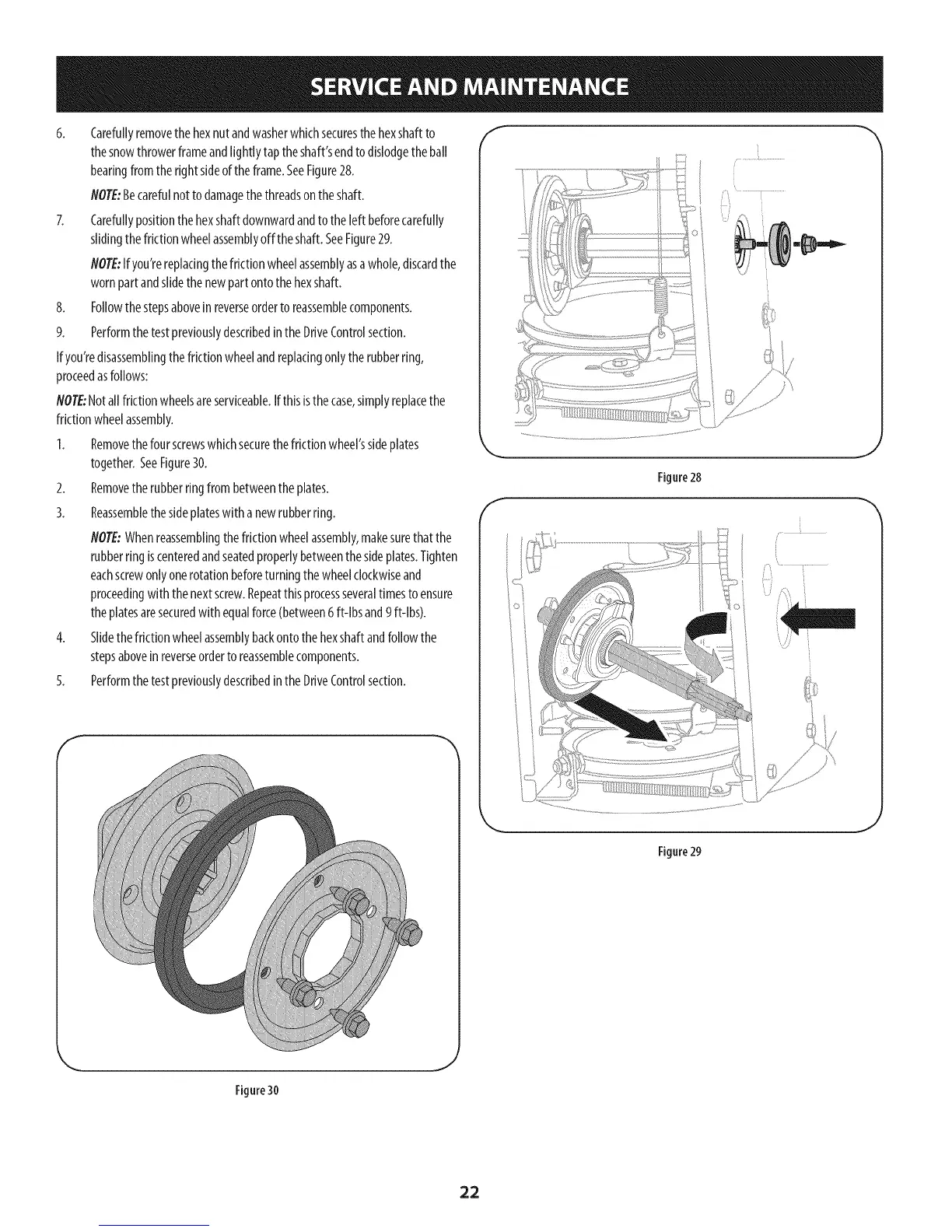

6. Carefullyremovethehexnutandwasherwhichsecuresthehexshaftto

thesnowthrowerframeandtightlytaptheshaft'sendtodislodgetheban

bearingfromtherightsideoftheframe.SeeFigure28.

NOTE:Becarefulnotto damagethethreadsontheshaft.

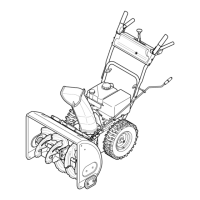

7. Carefullypositionthehexshaftdownwardandtothe[eftbeforecarefuNy

slidingthefrictionwheelassemblyoff theshaft.SeeFigure29.

NOTE:Ifyou'rereplacingthefrictionwheelassemblyasawhole,discardthe

wornpartandslidethe newpart ontothehexshaft.

8. Followthestepsaboveinreverseorderto reassemblecomponents.

9. Performthetestpreviouslydescribedinthe DriveControlsection.

If you'redisassemblingthefrictionwheelandreplacingonlytherubberring,

proceedasfollows:

NOTE:Notallfrictionwheelsareserviceable.Ifthisisthecase,simplyreplacethe

frictionwheelassembly.

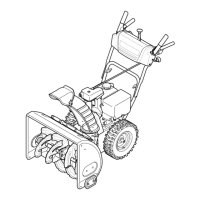

1. Removethefourscrewswhichsecurethefriction wheel'ssideplates

together.SeeFigure30.

2. Removetherubberringfrom betweenthe plates.

3. Reassemblethesideplateswith a newrubberring.

NOTE:Whenreassemblingthefrictionwheelassembly,makesurethatthe

rubberring iscenteredandseatedproperlybetweenthesideplates.Tighten

eachscrewonlyonerotationbeforeturningthewheelclockwiseand

proceedingwith thenextscrew.Repeatthisprocessseveraltimestoensure

theplatesaresecuredwith equalforce(between6 ft-lbsand9 ft-lbs).

4. Slidethefrictionwheelassemblybackontothehexshaftandfollowthe

stepsaboveinreverseorderto reassemblecomponents.

5. Performthetestpreviouslydescribedinthe DriveControlsection.

f

f

Figure28

J

Figure29

J

Figure30

,J

22

Loading...

Loading...