_w

r=AP=_ r =L|NI,t M Hequiredafter every 3rdto 5th

time thePowerSharp® Systemis usedto correctthe

side l_latesand depth gauges.

NOTE: If abrasive materials such as rocks, nails,

sand, or.dirt are contacted by the chain, the side

plates should be checked more often. Damage

to the cutters caused by abrasive materials

usually results in discoloration spots where the

chrome has been Worn away. Side plates should

be filed until these spots are removed.

Items Required: Gloves, 5!32" round file, File

holder, flat file, screwdriver, Vise.

1. Disconnect your saw from the power source.

2. Adjust the chain for proper tension, page 7.

3.'Clamp the bar in a vise to hold the chain

steady. Do not clamp the chain.

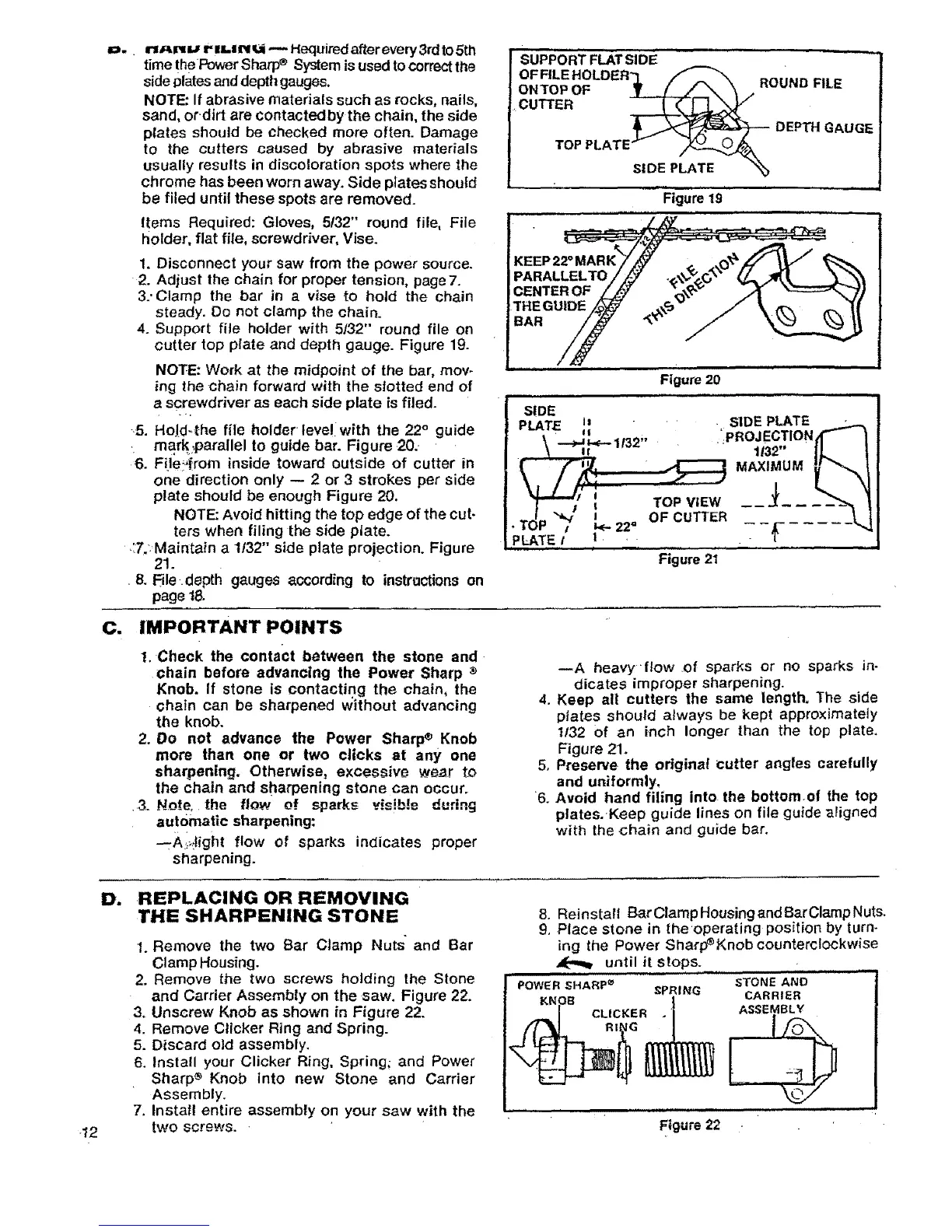

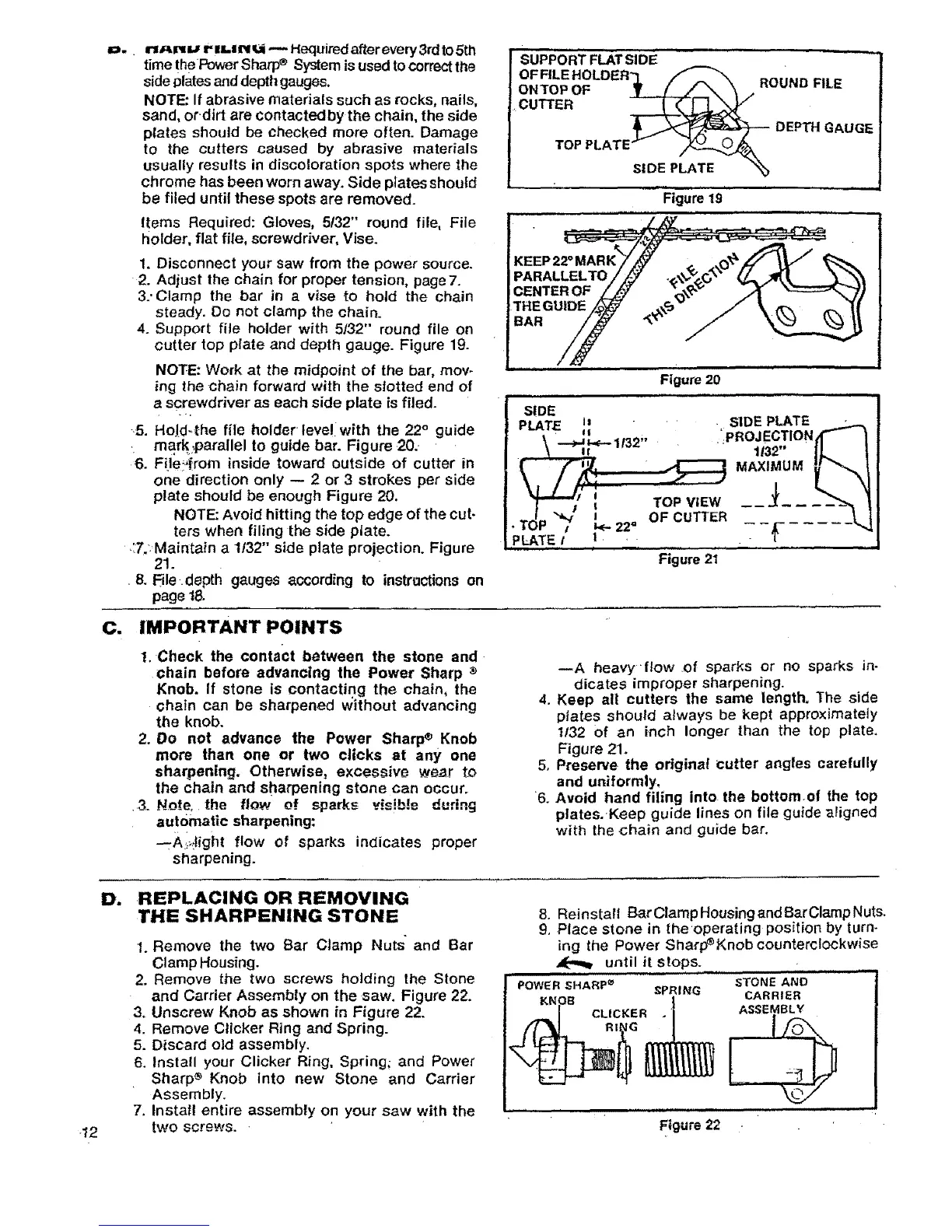

4. Support file holder with 5/32" round file on

cutter top plate and depth gauge. Figure 19.

NOTE: Work at the midpoint of the bar, mov-

ing the chain forward with the slotted end of

a screwdriver as each side plate is filed.

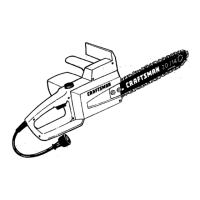

5. HoJd.{he file holder feve!iwith the 22° guide

mark:parallel to guide bar. Figure 20.

6. File_.,{rom inside toward outside of cutter in

one direction only -- 2 or 3 strokes per side

plate should be enough Figure 20.

NOTE: Avoid hitting the top edge of the cut.

ters when filing the side plate.

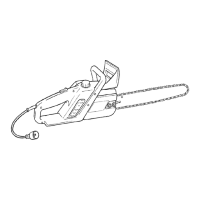

.:T.:Maintain a 1/32" side plate projection. Figure

21.

8. Ble.depth gauges according to instractions on

page l&

suPPoRT FLATSiDE ................ -

OFFILE HOLDER

ONTOP OF _-X_ i ROUND FILE

DEPTHGAUGE

TOPPLATE- ,/_

SIDE PLATE "_

Figure 19

CENTER OF

THEGUIDE

BAR

Figure 20

S!DE

PLATE is StDE PLATE

\ --_ L<---11._P,, , ':pROJECTION

.... 1132"

Figure21

C. IMPORTANT POINTS

1. Check the contact between the stone and

chain before advancing the Power Sharp •

Knob. If stone is contactin.g the chain, the

chain can be sharpened without advancing 4.

the knob.

2, Do not advance the Power Sharp® Knob

more than one or two clicks at any one

sharpening. Otherwise, excessive wear to 5,

the chain and sharpening stone can occur.

.3. No_re. the flow of =.sparks visi.b!e during 6.

automatic sharpening:

-.Ai,_ight flow of sparks indicates proper

sharpening.

--A heavyflow of sparks or no sparks in-

dicates improper sharpening.

Keep all cutters the same length, The aide

plates should always be kept approximately

t/32 of an inch longer than the top plate.

Figure 21.

Preserve the origina! cutter angles carefully

and uniformly,

Avoid hand filing into the bottom.of the top

plates.,Keep guide lines on file guide aligned

with the chain and guide bar.

D. REPLACING OR REMOVING

THE SHARPENING STONE

-12

1. Remove the two Bar Clamp Nuts and Bar

Clamp Housing.

2. Remove the two screws holding the Slone

and Carrier Assembly on the saw. Figure 22.

3. Unscrew Knob as shown in Figure 22.

4. Remove Clicker Ring and Spring.

5. Discard old assembly.

6. Install your Clicker Ring, Spring; and Power

Sharp ® Knob into new Stone and Carrier

Assembly.

7. install entire assembly on your saw with the

two screws.

8. Reinstall BarClampHousingandBarClampNuts.

9. Place stone in the operating position by turn-

ing the Power Sha_p_Knobcounterclockwise

,_ until it stops. . --

SPRING

STONE AND

CARRIER

ASSEMBLY

Loading...

Loading...