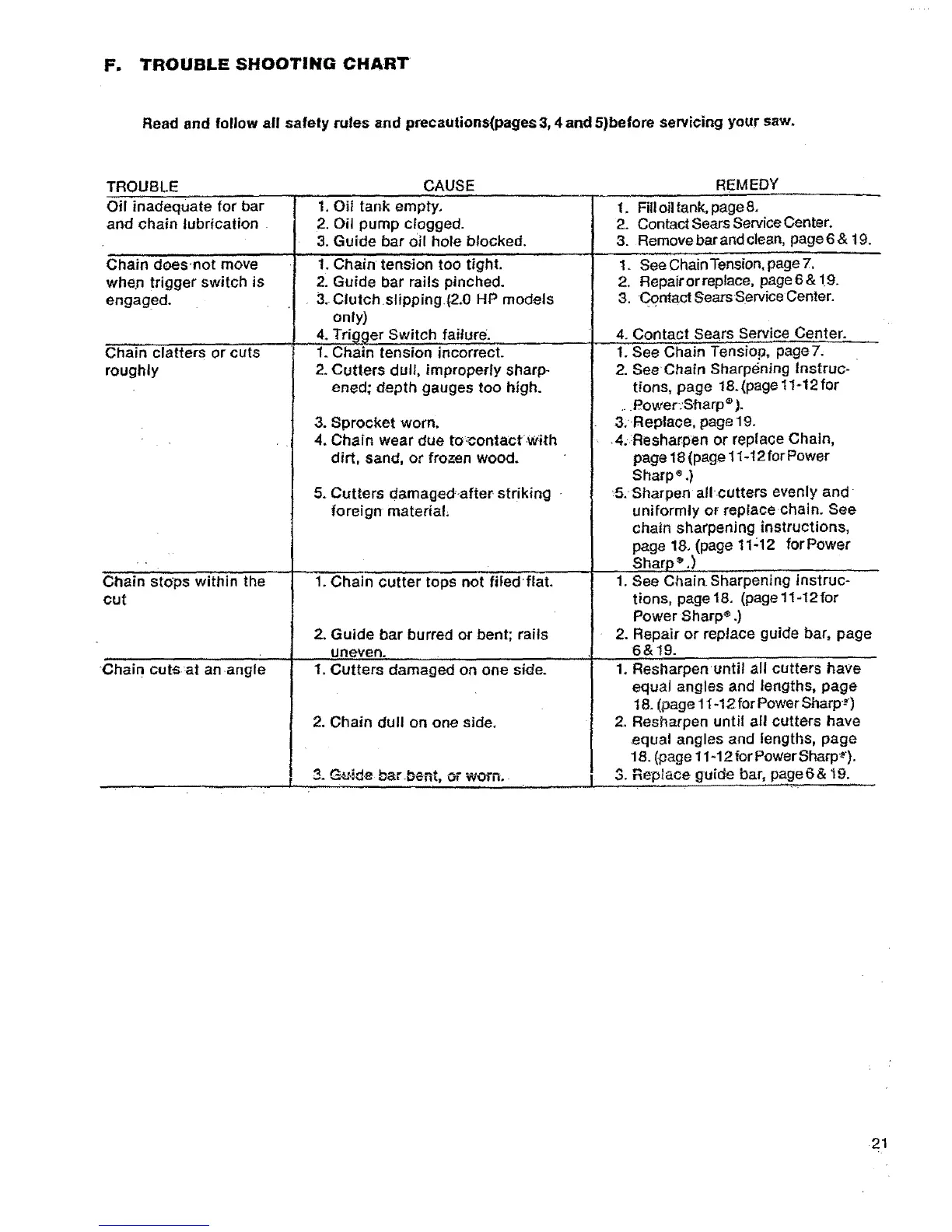

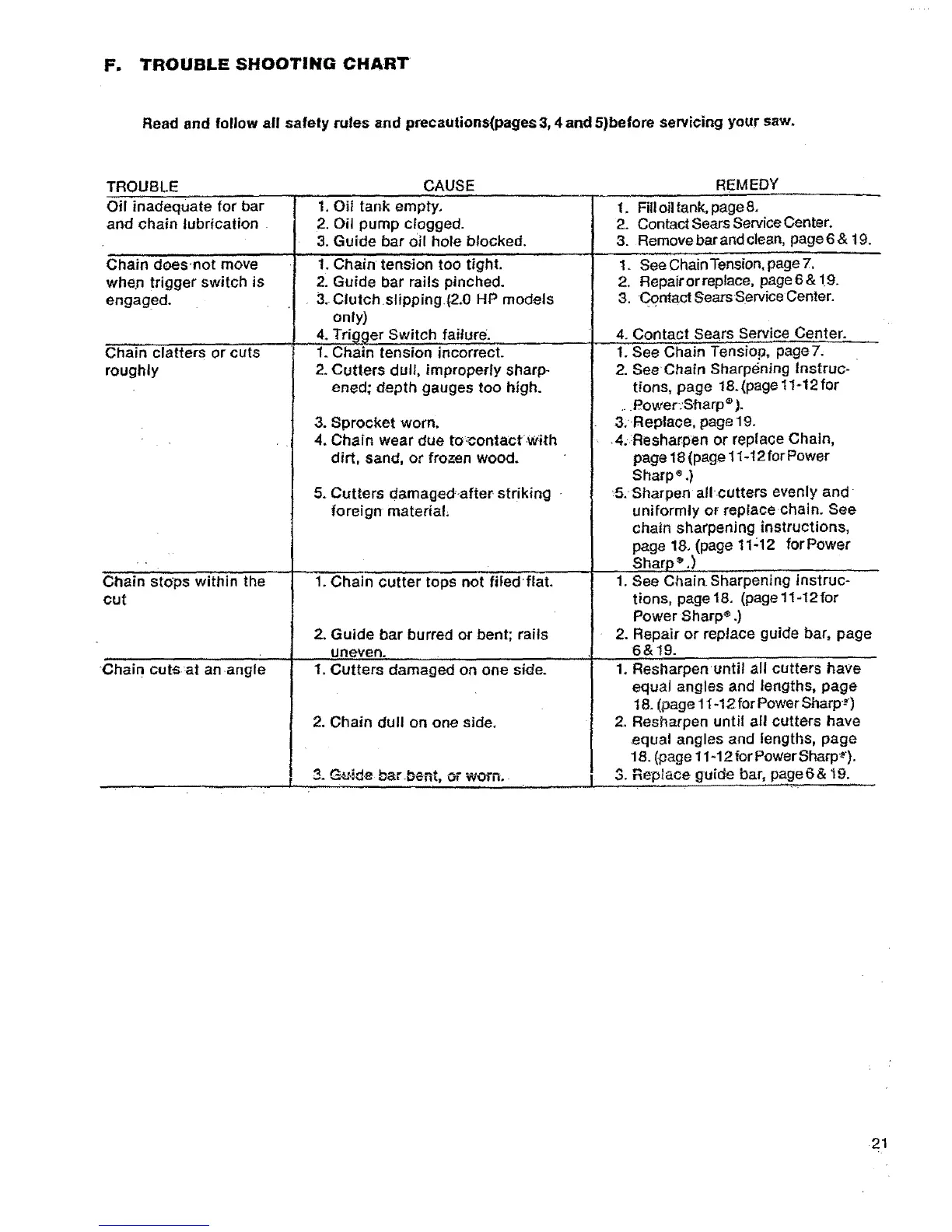

F. TROUBLE SHOOTING CHART

Read and follow all safety rules and precautions{pages 3, 4 and 5)before servicing your saw.

TROUBLE

Oil inadequate for bar

and chain lubrication

Chain does,not move

when trigger switch is

engaged.

Chain clatters or cuts

roughly

Chain stops within the

cut

Chain cutsat an angle

CAUSE

1, Oil tank empty,

2. Oil pump clogged.

3. Guide bar 0il hole blocked.

1. Chain tension too tight.

2. Guide bar rails pinched.

3. Clutchslipping(2.0 HP models

only)

4. Trigger Switch failure.

I. Chain tension incorrect.

2. Cutters dull, improperly sharp-

ened; depth gauges too high.

3. Sprocket worn.

4. Chain wear due to contactW:ith

dirt, sand, or frozen wood.

5. Cutters damaged'after striking

foreign material,

1. Chain cutter tops not filed flat.

2. Guide bar burred or bent; rails

uneven.

1. Gutters damaged on one side.

2. Chain dull on one side,

3. G_,_de bar.bent, or worn°

REMEDY

1. Filloil tank, page 8.

2. Contact Sears Service Center.

3. Remove bar and clean, page 6 & t9.

1. See Chain Tension, page 7.

2. Repairorreplace, page6& 19.

3. Contact Sears Service Center.

4. Contact Sears Service Center.

1. See Chain Tensiop, page7.

2. See Chain Sharpening Instruc-

tions, page 18.(page 11*12for

.. Power:Sharp® ).

3..Replace, page 19.

A.Resharpen or replace Chain,

page 18 (page 11-12 for Power

S harp _.)

5. Sharpen aft.cutters evenly and

uniformly or replace chain. See

chain sharpening instructions,

page 18. (page 11:12 forPower

Sharp _ .)

1. See Chain. Sharpening instruc-

tions, page18. (page11-12for

Power Sharp ®.)

2. Repair or replace guide bar, page

6&19.

1. Resharpenuntil all cutters have

equal angles and lengths, page

t 8. (page 11-12 for Power Sharp -_)

2. Resharpen until all cutters have

equal angles and lengths, page

18. (-page11-12 for Power Sharp'_).

3. Replace guide bar, page6& t9.

21

Loading...

Loading...