C. CHAIN REPLACEMENT

1.) Replace the chain when cutters or links

break.

2.) See your Sears Service Centerto replace

and sharpen individual cutters to match

your chain.

3.) Always replace a worn sprocket when

installing a new chain toavoid excessive

wear to the chain.

2. GUIDE BAR MAINTENANCE

• Conditions which can require guide bar

maintenance:

saw.cuts to one side

saw has to be forced through a cut

inadequate supplyof oiltobar and chain.

,, Check the condition ofthe guide bar each

time the chain is sharpened. A worn guide

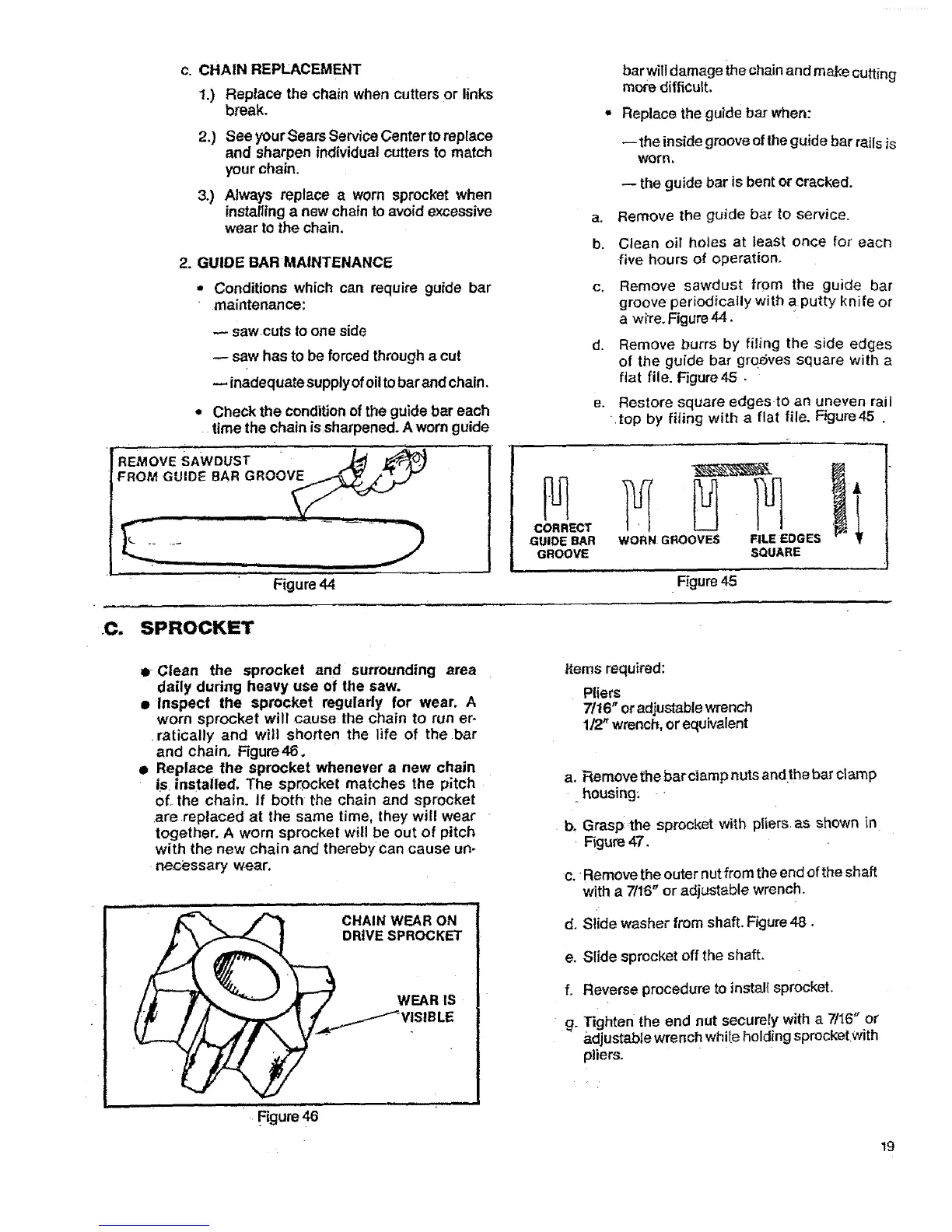

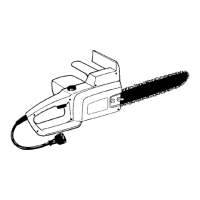

REMOVESAWDUST " _ ""'_

FROM GUIDE BAR GROOV_j_/"

Figure44

a.

b.

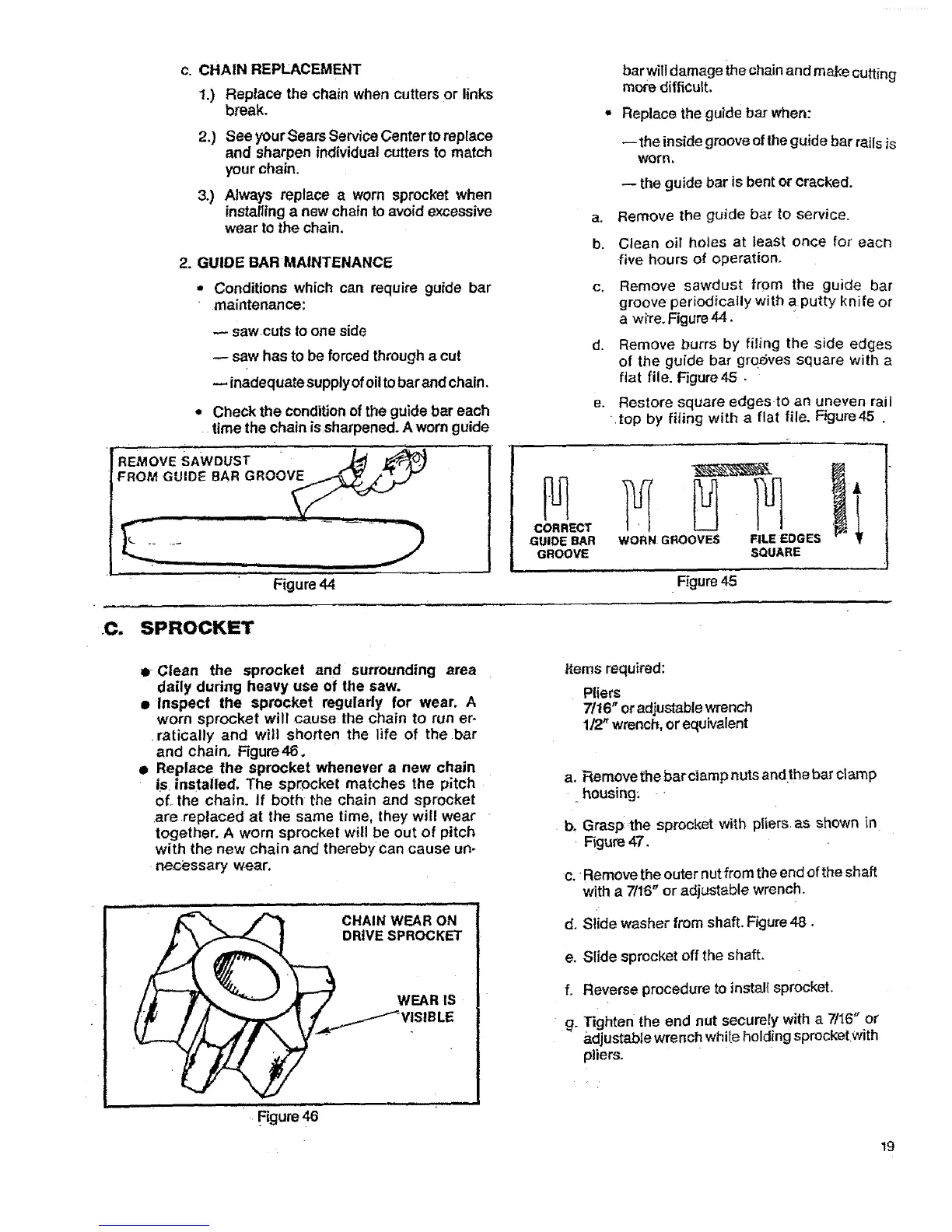

C. SPROCKET

• Clean the sprocket and surrounding area

daily during heavy use of the saw.

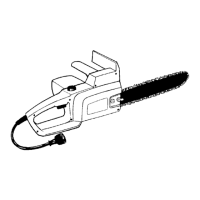

• Inspect the sprocket regularly for wear. A

worn sprocket will cause the chain to run er-

•ratically and will shorten the life of the bar

and chain, Figure46o

• Replace the sprocket whenever a new chain

iS_installed. The sprocket matches the pitch

of the chain. If both the chain and sprocket

are replaced at the same time, they will wear

together. A worn sprocket will be out of pitch

with the new chain and thereby can cause un-

necessary wear.

WEAR IS

' g re46

C_

bar will damage the chainan dmake cutting

more difficult,

Replace the guide bar when:

-- the inside groove of the guide bar rails is

worn,

the guide bar is bent or cracked.

Remove the guide bar to service.

Clean oil holes at least once for each

five hours of operation.

Remove sawdust from the guide bar

groove periodically with a putty knife or

a w_re. Figure44.

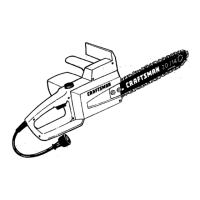

d. Remove burrs by filing the side edges

of the guide bar grodves square with a

fiat file. Figure45.

e. Restore square edges to an uneven rail

,top by fiiing with a flat file. F_gure45 .

GUIDE BAR WORN GROOVES FILE EDGES

GROOVE SQUARE

Figure 45

Items required:

Pliers

7116"or adjustable wrench

1/2_wrench, or equivalent

a. Remove the bare|amp nuts andthe bar clamp

.housing:

b. Grasp_the sprocket with pliers as shown in

Figure 47,

c. Remove the outer nutfrom the end of the shaft

with a 7116"or adjustable wrench.

d, Slide washer from shaft. Figure48.

e. Slide sprocket off the shaft.

f. Reverse procedure to instal{ sprocket.

g. Tighten the end nut securely with a 7116"or

• adjustable wrench while holding sprocket with

pliers.

19

Loading...

Loading...