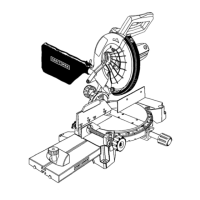

Do you have a question about the Craftsman PROFESSIONAL 315.273731 and is the answer not in the manual?

Step-by-step guide to assemble the saw's leg stand.

Securing the saw to the assembled leg stand.

Installing the handwheel for adjusting blade height.

Mounting the yoke assembly onto the carriage.

Procedure to ensure the saw arm is at 0° for cross cuts.

Squaring the blade to the table at a vertical bevel.

Ensuring the blade is square to the fence for rip cuts.

Aligning the blade parallel to the table at 90° bevel.

Overview of the saw's capabilities and intended use.

Procedure for making a standard cross cut.

Procedure for making a miter cut with an angled arm.

Procedure for making a bevel cut with an angled blade.

Procedure for making a cut with both angled arm and blade.

Procedure for performing a rip cut.

| Model Number | 315.273731 |

|---|---|

| Type | Circular Saw |

| Blade Size | 7-1/4 inches |

| Blade Diameter | 7-1/4 inches |

| No Load Speed | 5000 RPM |

| Weight | 11.5 lbs |

| Depth of Cut at 90 degrees | 2-7/16 inches |

| Depth of Cut at 45 degrees | 1-3/4 inches |

| Motor | 15 Amps |

| Bevel Capacity | 50 degrees |

Loading...

Loading...