Figure 8-1: No person standing here during filling.

To fill the tank, proceed as follows:

Refer to the safety notes in section 8.4, on page

22.

The tank must never be left unattended during

the filling stage.

The pressure of the supply tank or the

filling line must not exceed 3 bars.

Pressure as read on the gauge does not

need to be monitored.

1. Before starting, blow dry air or nitrogen through the

lines and the valves to remove any moisture.

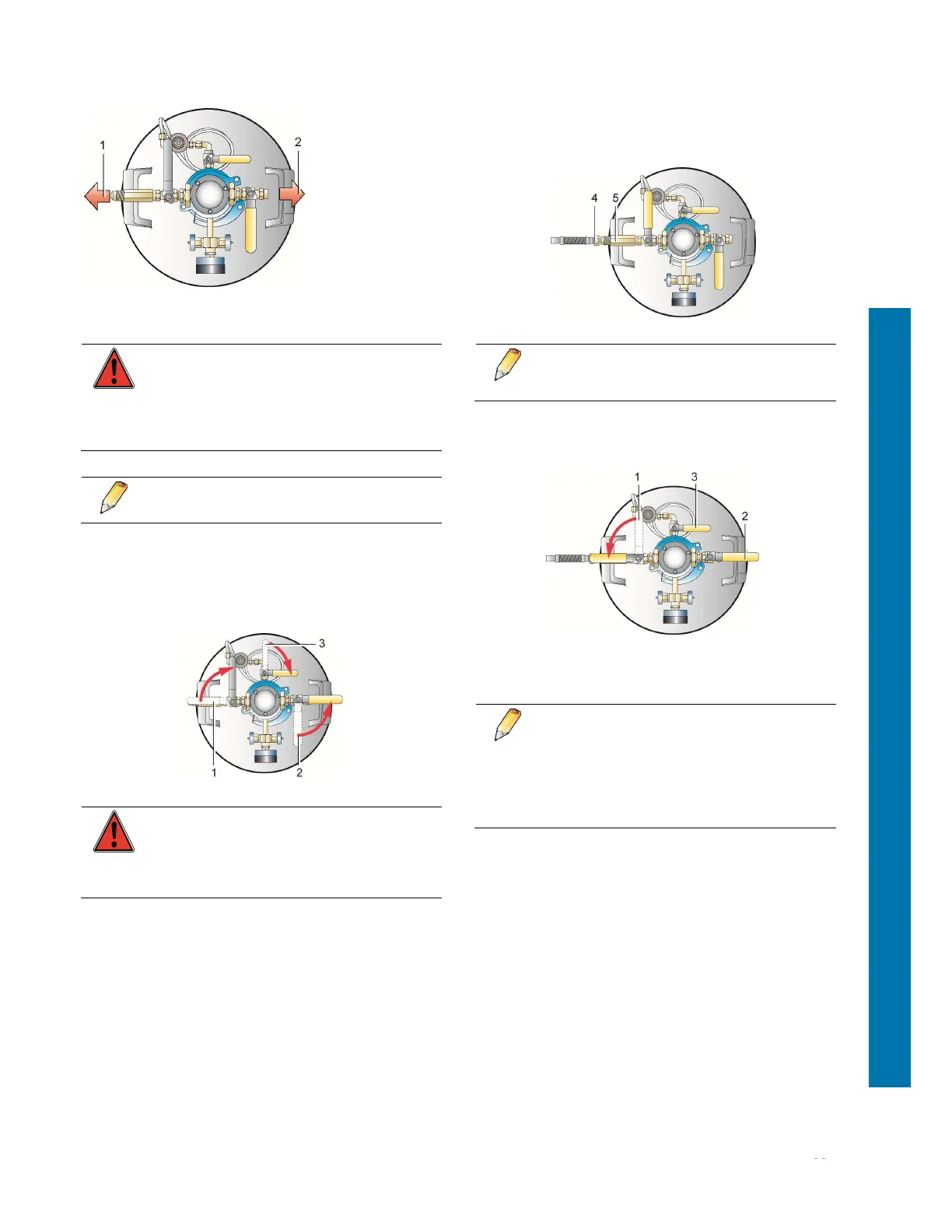

2. Open the vent valve (2). Close the

filling/withdrawal valve (1). Close the pressure-

building valve (3).

This enables you to check that the tank is

no longer pressurized. If the tank were still

pressurized (a jet of gas would appear),

there would be a danger of cryogenic

burns.

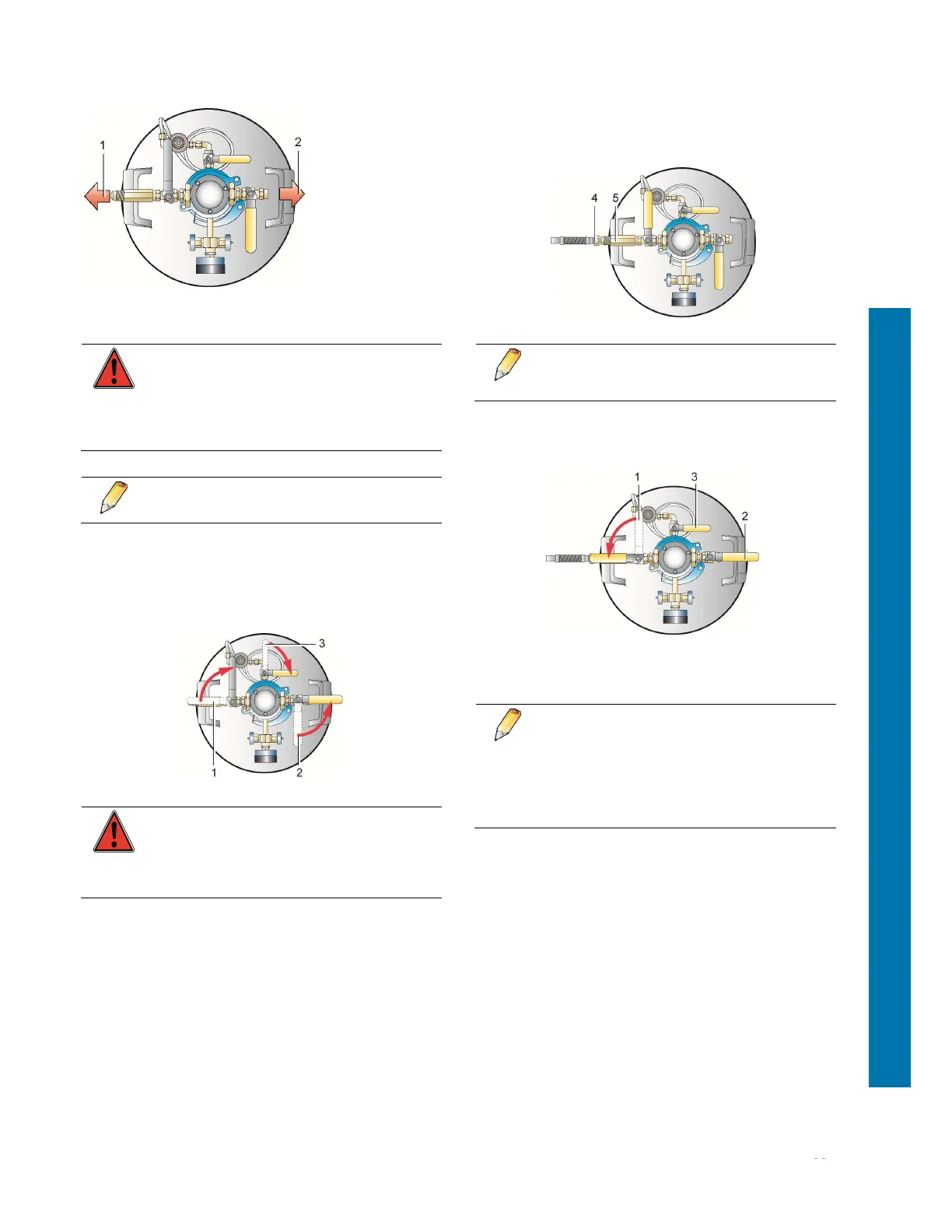

3. Fit the filling valve's connector (5) onto the supply

line by means of a transfer hose (

130 TC

or

130/130

) (4).

To limit filling time, it important to use the

shortest possible transfer line (1.1 or

1.5 m).

4. Open the TP filling valve (1). Check that the

pressure-building valve (3) is closed. Check that

the vent valve (2) is open.

5. Open the line or supply tank's valve slightly (to

allow a low flow).

If the tank is not cold (new tank, or tank has

not been used recently) you must open the

withdrawal valve of the supplying tank very

gently so as not to send too much liquid

nitrogen into the tank. This precaution will

prevent excessive pressure in the tank

being filled.

6. Now open the line (or supply tank) valve gradually

to speed up the filling operation.

Opening the withdrawal valve of the supplying tank

gradually prevents the pressure in the vessel being filled

from rising too suddenly.

Loading...

Loading...